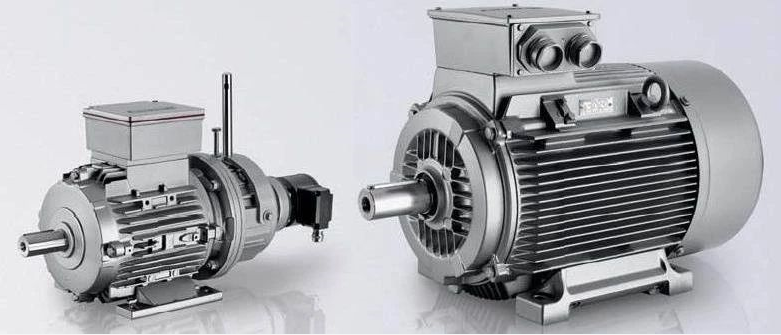

Winding type and characteristics of the motor

The winding is the key component of the motor, and it is also the link that is relatively easy to be damaged. It is affected by inductance, thermal and mechanical vibration, and environmental factors. The winding is the main factor that determines the life and operating reliability of the YE3 motor. Winding cost is the main component of the total cost of the motor. The materials used in winding are greatly affected by the market economy.

picture

The armature winding is installed in the slot of the armature core (or stator core). According to its structure and manufacturing method, it can be divided into soft winding and hard winding.

1

Soft winding

The soft winding is wound by an insulated round conductor. It is usually used for small motors with semi-enclosed slots, and the working voltage does not exceed 500 volts. The winding can be made into a single layer or a double layer, in which one coil edge is scattered in each slot of the single layer, and two coil edges are scattered in each slot of the double layer. From a technical analysis point of view, it is recommended to use single-layer windings for small AC motors below 10 kilowatts, because there is no interlayer insulation in the slot and it is convenient to plug in. The slot space utilization is good, but the ends of the winding overlap each other and are not easy to shape. For motors above 10kW, the inner diameter of the magnetic core is larger, and double-layer windings are more often used, because it can choose a suitable short pitch to weaken the harmonic magnetic potential, and the winding ends are arranged neatly.

In addition, there are single-layer and double-layer hybrid windings and Y-delta hybrid windings in AC motors. In single-layer and double-layer hybrid windings, part of the groove is single-layer, and the other part of the groove is double-layer. Compared with the double-layer winding with the same short distance, the winding end connection is shorter, which is more advantageous for 2P motors.

In Y-delta hybrid windings, the coils of each pole and phase are divided into two types, namely triangular and Y-shaped. The number of turns and diameter of the two coils are different. When the coil is inserted, the two coils are alternately distributed. When connecting, the delta system and the Y-shaped system are connected separately and then mixed into a connection method. This kind of winding can eliminate the high-order harmonic components in the magnetic potential and improve the fundamental wave distribution coefficient. However, the insertion and wiring of the two windings is troublesome and error-prone, so process management is very important.

The soft winding can be divided into embedded soft winding, winding soft winding and penetrating soft winding according to different installation methods.

(1) When the embedded soft winding is manually operated, the multi-turn scattering coil is inserted into the core slot through the slot. Mainly used in the stator or winding rotor of small AC motors and small DC armatures. Mechanized installation technology has been promoted for mass production of small stators.

(2) The insulated round wire of WOUND-IN soft winding is directly wound in the core slot, which is mainly used for DC armature or AC rotor with fewer poles. Usually, manual winding is used. For mass production of DC armatures or rotor windings, special insertion machines are used.

(3) The core of the penetrating soft winding is a closed groove or a semi-closed groove. The width of the groove is smaller than the embedded diameter. The conductor is an insulated round wire or stranded wire, which passes through the two ends of the groove and rotates in turn. The wiring work is very heavy and is only suitable for special motors, such as intermediate frequency motors and water-filled submersible motors.

2

Hard winding

The hard winding is composed of formed coils, which are made of insulated flat conductors or conductors. According to different batch methods, it can be divided into embedded and plug-in type.

(1) The iron core of the embedded winding is slotted or semi-slotted, and the winding element is a multi-turn or single-turn formed coil. When the multi-turn formed coil is used in an open slot, it is generally insulated from the ground and has been insulated. When used for semi-slotting, the coil is formed by double insulated flat wires, which are divided into slots and assembled into slots.

Single-sided forming coils can be divided into two types: full toroidal coils and half toroidal coils. The full-circle type is used for medium-sized DC armatures, and the semi-circular type is used for large-scale steam turbine generators and hydroelectric generators.

Generally, a single-sided forming coil has a large conductor cross-section, which is composed of a plurality of insulated flat conductors and is bent on a special mold or forming device. For large generators with conductors exceeding 300 kW, the leakage magnetic field in the grooves will cause uneven conductor current distribution and increase winding losses. In order to overcome this shortcoming, the coil is usually made of a plurality of insulated flat conductors by transposition braiding.

(2) The hard coil core is inserted into a closed slot or a semi-closed slot, and the winding element is a half coil rod. When used in the winding rotor of an asynchronous motor, the coil conductor is bent by a copper strip. Start bending one end and insert the other end into the groove before forming. For large motor stators, some are braided with involute semicircular transposition coils, which are welded with parallel head sleeves after being inserted into the slots. Plug-in windings are also used in squirrel cage windings of asynchronous motors, damper windings or start windings of synchronous motors, and compensation windings of large DC motors.

The pole winding is installed on the core of the magnetic pole. According to the different materials and winding methods used, it can be divided into two types: insulated wire winding (round or flat wire) and ribbon winding. Ribbon windings can be divided into flat windings (bending on the wide side) and flat windings (bending on the narrow side).

The winding manufacturing process varies with the structure. The key to soft winding manufacturing is bulk winding. Take the embedded soft winding as an example, its main manufacturing process is to check the insulation treatment of the winding coil scattered line wiring. Hard winding manufacturing is the key to coil manufacturing. According to different insulation structure and processing technology, the manufacturing method of the coil is also different. Taking the slotted embedded hard disk winding as an example, its main manufacturing process is the shuttle or wave coil protruding forming inter-turn insulation gel treatment components, and the winding insertion inspection is checked by grounding insulation thermocompression molding.

BACK

BACK