What is the role of air gap magnetic flux in the motor ?

Air gaps are one of the main issues in motor design, and electromagnetic devices contain low-resistance materials (such as iron) in the magnetic circuit, which minimizes the electrical energy required to generate the magnetic field. Gaps in magnetic circuits are usually unavoidable, they contain air, which provides a high resistance to the magnetic flux, such gaps need to be detrimental in terms of magnetizing current and associated electrical losses.

The air gap is the non-magnetic part of the magnetic circuit that is usually connected in series with the rest of the circuit so that a significant portion of the magnetic flux flows through the gap. Air gaps can be filled with non-magnetic materials such as gas, water, vacuum, plastic, wood, etc., not necessarily just air.

1. Effect of air gap

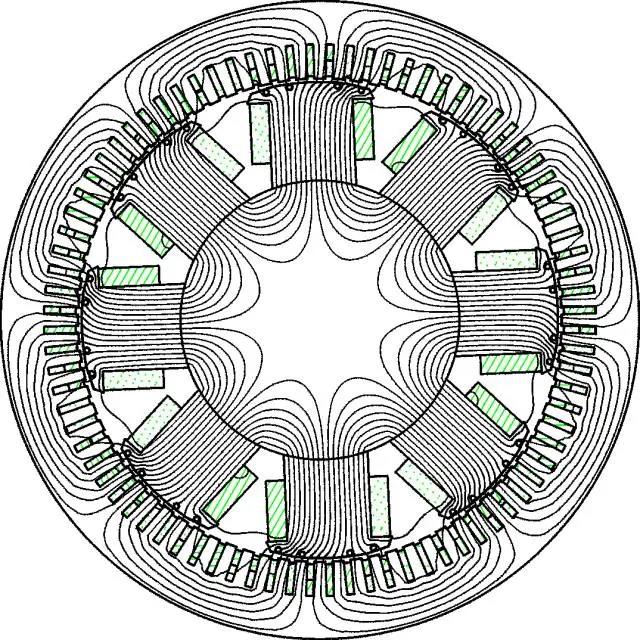

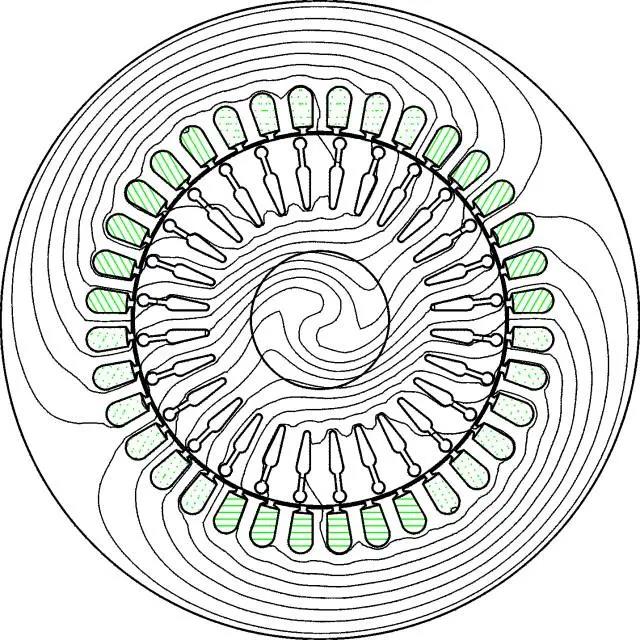

The stator and the rotor are the two main parts of the motor. They are magnetically coupled, and the energy is transmitted through the machine from both sides through the magnetic field. The small air gap can bring low noise and less unbalanced magnetic pull. Due to the increased reluctance of the air gap, the magnetic flux diffuses into the surrounding medium, causing the flux fringing effect, an unwanted phenomenon that increases proximity and eddy current losses in conductors located near the air gap. The air gap causes a reduction in the flux linkage between the rotor and stator, which is seen as a loss. Since the magnetic flux between the stator and rotor windings is reduced, which weakens the transfer of magnetic energy, a large air gap means more magnetizing current and a low power factor, and the positive side of the large air gap has a better effect on the overload capacity of the motor.

The air gap may be an integral part of ensuring the correct performance of the device, it should be as small as possible, the form, shape and size of the air gap depends on the type and shape of the magnetic circuit, which is determined by the principle of operation, performance, size, efficiency and many other technologies factors determine. In rotating machinery, due to the physical movement required between the stator and rotor, an air gap is usually not required, but inevitably, the minimum practical air gap for industrial machines is about 0.2 mm. In relays, the air gap is usually an integral part that facilitates movement between the stationary parts (such as windings and cores) and the active armature, mechanically driving the connection or disconnection of the main electrical contacts. In conventional transformers, air gaps are usually avoided, and the role of the transformer is to instantaneously transfer the energy of the primary winding to the secondary winding without the need for energy storage.

2. Air gap of the motor

The air gap is the gap between the rotor and stator of a motor. A "free open space" physically separates the two motor components. Since the rotor and stator are not magnetically coupled, there is an air gap between them. When properly fed (depending on the type of machine), the magnetic field is established and connects the stator and rotor, due to the presence of the air gap, some part of the magnetic field passes through the rotor or the stator, but not both, this part of the magnetic flux is called Leakage or air gap flux (as it passes through the air gap alone). This leakage flux does not play a role in power transfer because it is not connected to neither the stator nor the rotor, and the current created to create the leakage flux loses power to the machine.

Both the stator and the rotor are made of magnetic materials (usually silicon steel). The higher the magnetic permeability of the core medium, the smaller the magnetic resistance, and the lower the magnetic permeability of the air; Larger results in less power. Therefore, the air band length is kept as short as possible in order to separate between the rotor and stator and to provide the required mechanical balance of the machine. A free-spinning rotor leaves a gap of about 2 mm as a sacrificial loss of magnetic force, allowing normal mechanical operation of the motor or generator.

In synchronous and DC motors, two independent magnetic fields interact in the air gap, and the AC magnetic field generated by the armature (stationary in a synchronous motor and rotating in a DC motor) distorts the supply of the DC magnetic field, reducing efficiency, Decreased motor performance, increasing the air gap will reduce the effect of "armature reaction", so the air gap of these machines will be several times larger than that of an induction motor. In an induction motor, the electromotive force induced in the rotor windings is the electromotive force induced by each other. When the electromotive force induced in the rotor is generated by mutual induction, the induction motor can be regarded as a resolver. The larger the air gap, the greater the leakage flux. Larger, the smaller the mutual magnetic flux, thereby reducing the electromotive force, current and torque of the rotor.

In a synchronous motor, the magnetic flux is set separately by the magnetic field winding, and the electromotive force induced in the stator armature winding is not generated by mutual induction, but is a dynamic induced electromotive force generated by the relative motion between the magnetic field and the conductor. Therefore, it is not Consider air gaps. For salient pole motors, the air gap will be much larger in the area between the poles. The air gap required to separate the rotating rotor from the stator in a generator should be as small as possible to reduce magnetizing power requirements, but large enough to prevent contact between the two, manufacturing tolerances in their dimensions, or due to mechanical deflection and Movement caused by loose support bearings.

3. Conclusion

Through the above understanding, we understand the importance of the air gap to the motor in the design and construction of the entire motor. In the case of motors with the same appearance and the same size, the unreasonable air gap design will lead to a decrease in output torque; the back EMF of the rotor to the coil will decrease, resulting in an increase in current, power consumption and motor heating.

The air gap is the space between the stator and rotor of the motor. The stator does not rotate, the rotor needs to rotate, so the air gap is necessary, and the size of the air gap varies according to the motor. Generally speaking, the air gap of the asynchronous motor is small, and the air gap of the synchronous motor is large. If the air gap increases, the magnetic flux leakage will increase; if the air gap decreases, the rotor iron core will soon rub against the stator iron core due to the wear of the bearing. Reduce motor life.

The above problem is to let more customers understand the design principle of the entire motor, not just the appearance of the motor, but the quality control needs to pay attention to the design and production quality control of every detail. Our BG Motor technical team engineers pay great attention to a detail of motor design to ensure that the motor does not heat up and maximizes operating efficiency, reducing the loss of electrical energy.

BACK

BACK