How to distinguish between bonded NdFeB magnets and sintered NdFeB magnets? --- BG Motor

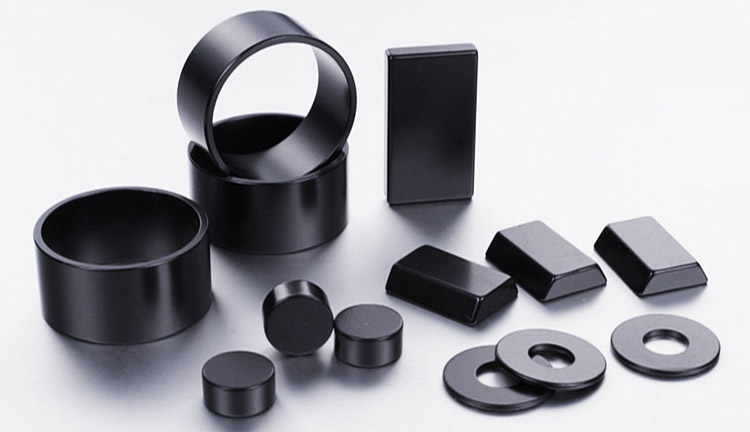

Neodymium magnets can be called NdFeB magnets, which is a general term for strong magnets. The chemical formula is Nd2Fe14B, and it is one of the artificial permanent magnet materials with the strongest magnetic force so far. The material grade of NdFeB magnets is N35-N52, which can be processed into different shapes according to specific requirements, such as round, square, punching, magnetic tile, magnetic rod, convex or trapezoidal, etc. Therefore, how to distinguish between bonded NdFeB and sintered NdFeB?

In fact, both magnets are NdFeB. These two magnets are distinguished according to their production process. Bonded NdFeB magnets are formed by injection molding, and sintered NdFeB magnets are formed by high temperature heating.

1. Production process of bonded NdFeB magnets

Bonded NdFeB magnets are formed by injection molding. The density is lower than that of sintered NdFeB because it contains a resin matrix, and the density varies according to the content of the resin matrix. However, sintered NdFeB magnets are heated at high temperature through a complicated process and do not contain non-magnetic resin components. Therefore, the performance of sintered NdFeB is higher than that of bonded NdFeB.

2. Production process of sintered NdFeB magnets

Sintered NdFeB magnets are anisotropic magnets produced by powder sintering. Generally, only blanks can be produced by sintering, and magnets of various shapes need to be mechanically processed (such as wire cutting, slicing, grinding, etc.). Sintered NdFeB is a hard and brittle material that is difficult to process, so it has large losses during processing, high cost, poor dimensional accuracy, poor corrosion resistance, and the surface needs electroplating, but the advantage is high performance, which has reached more than 50M.

To sum up, the magnetic properties of bonded NdFeB magnets are relatively low, isotropic bonded magnets are usually below 10M, while anisotropic bonded magnets can reach about 16M. However, injection-molded NdFeB magnets also have their irreplaceable advantages. For example, the effective utilization rate is relatively high; the performance can be adjusted according to the needs of different products; the injection-molded magnets have high resistivity, which can effectively reduce eddy current loss and motor heating when used in the field of high-speed rotors; the sintering process is not suitable for molding complex shapes and structures products, and injection molding can easily solve this problem.

Of course, the different materials of NdFeB magnets are recommended according to the different scenarios of customers. If you are not very clear about the magnetic materials, you can contact the customer service of our official website at any time, and they will contact and recommend to you professionally.

BACK

BACK