Speed control method and rotation direction change of brushless dc motor

At present, DC brushless motor is widely used in medical, robot, automobile, automation equipment, etc., because brushless motor does not need carbon brush, and it is convenient to use with long life and low noise. But in order to better use the Brushless DC motor, we need to control its speed and direction of rotation. Now let's talk about how we can control the speed and direction of the brushless DC motor.

1. Speed Control

1.1 Voltage Control:

Generally, the brushless motor will match a driver. By changing the output voltage of the driver, the input voltage of the brushless motor can be controlled to adjust the motor speed.

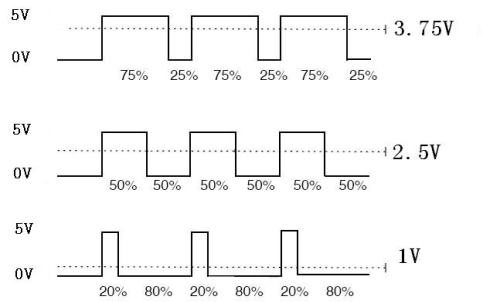

1.2 PWM Speed Control:

PWM speed control is the method of pulse width modulation. The so-called PWM is a pulse width modulator, which provides the motor with a pulse width adjustable pulse electricity with a certain frequency. The greater the pulse width, i.e. the greater the duty cycle, the greater the average voltage provided to the motor, and the higher the motor speed. On the contrary, the smaller the pulse width, the smaller the duty cycle. The smaller the average voltage supplied to the motor, the lower the motor speed.

1.3 Series Resistance Speed Control:

A potentiometer can be connected in series, but the efficiency is low and only small power motors can be used. If you want to use resistance speed control for high-power motors, you have to spend a lot of time to find a small resistance value and large power resistance. From the perspective of working efficiency, it is not cost-effective. Therefore, it is not recommended to use resistance speed control for high-power or small power brushless motors.

2. Rotation Direction Change

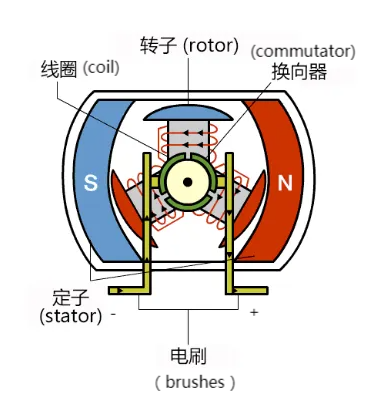

As a permanent magnet DC brush motor, the operation is very simple. Just change the positive and negative pole directions of the power supply, and the motor can be reversed.

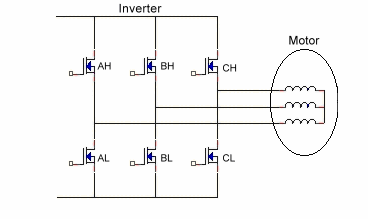

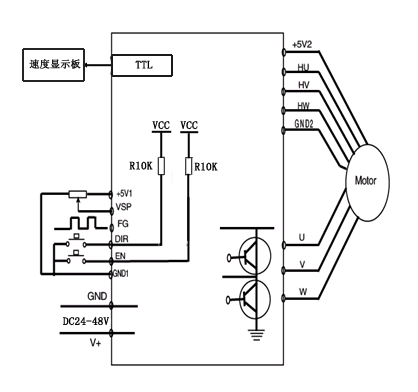

The brushless DC motor needs to change the direction of rotation, such as from Clockwise (CW) to Counter Clockwise (CCW). According to the current position of the motor rotor sensed by the hall sensor, use the logic circuit to change the conduction sequence of the power switch transistors. AH, BH, CH, AL, BL, CL in the converter make the current flow through the motor coil in sequence to generate a clockwise (or reversed) rotating magnetic field, which interacts with the rotor magnet, so that the motor can rotate CW/CCW. When the motor rotor rotates to the position where another group of signals is sensed by the Hall sensor, the control unit turns on the next group of power transistors, so that the circulating motor can continue to rotate in the same direction until the control unit decides to turn off the power transistors if the motor rotor is stopped, and the power transistors are turned on in reverse order if the motor rotor is reversed.

In operation, when DIR is connected to GND1, the motor reverses (counterclockwise); When DIR is disconnected or connected to+5V1, the motor rotates clockwise.

BACK

BACK