Client: Sfintini

Industry: Industrial Manufacturing

Cooperation Time: 2022

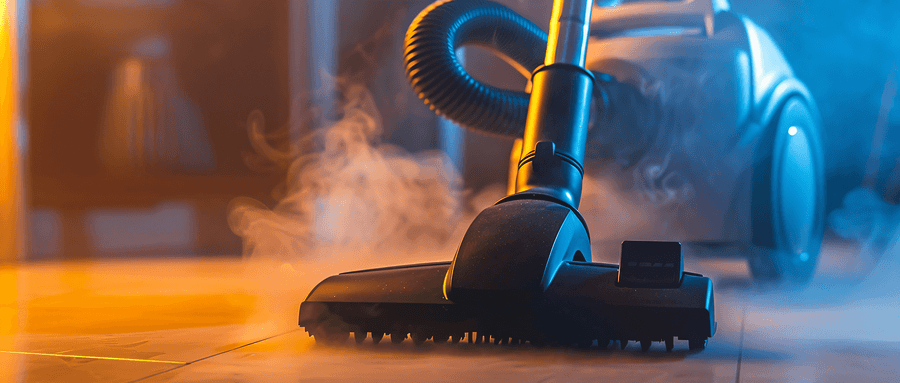

A smart manufacturing factory in Germany plans to upgrade its workshop ventilation system to increase production efficiency and improve the working environment. They needed industrial blowers to provide strong airflow to the shop floor while reducing noise levels to improve worker comfort. The project also required high durability and low energy consumption to reduce maintenance and operating costs.

1. High air volume demand: The workshop area is up to 5000 square meters, and the blower is required to provide stable and strong air volume to ensure air circulation.

2. Low noise requirements: The noise needs to be controlled below 65dB to avoid disturbing the workshop staff.

3. Durability and continuous operation capability: The factory workshop requires the equipment to run 18 hours a day, and the blower must have high reliability and long life.

4. Energy efficiency and environmental protection requirements: The customer required the motor to pass CE and RoHS certification and meet EU energy efficiency standards to reduce energy consumption.

5. Environmental adaptability: The equipment needs to operate stably in high temperature and high humidity environment, and the protection level needs to reach IP55 or above.

BG Motor provided the customer with a customized industrial blower solution with a high-performance AC motor, as follows:

High airflow design

Thanks to the optimized blade and motor matching, the blower can provide up to 5,000 m³/h of airflow to meet the air circulation needs of large workshops.

Low-noise operation

BG Motor's AC motor has greatly improved the working environment of the workshop by optimizing the electromagnetic design and selecting low-noise bearings to control the operating noise below 63dB.

Long life and high reliability

The motor is manufactured with high-quality materials and equipped with an efficient heat dissipation system that maintains stable performance for 18 hours of continuous operation and a service life of more than 30,000 hours.

Energy saving and environmental protection

The AC motor design with energy efficiency class IE3 reduces energy consumption by about 15%, which meets the customer's strict requirements for energy conservation and emission reduction.

Adapts to harsh environments

The motor housing is designed to achieve IP55 protection level, which is dustproof and waterproof, and uses high-temperature resistant painted coils to operate stably in high-temperature and high-humidity environments.

The upgraded industrial blower system has significantly improved air quality on the shop floor, with workers reporting a more comfortable working environment and a 12% increase in productivity. At the same time, due to the reduction of energy consumption, the customer saves about 15% of the annual electricity cost. The customer highly recognized the cooperation and planned to promote BG Motor's industrial blower solutions in other workshops.

BG Motor focuses on providing high-performance industrial motor solutions to global customers, if you have similar needs, welcome to contact us to create an efficient and environmentally friendly industrial future!

BACK

BACK

BG Motor insisting on producing the best quality motors for our customers.