BG Motor-Eight causes of motor heating

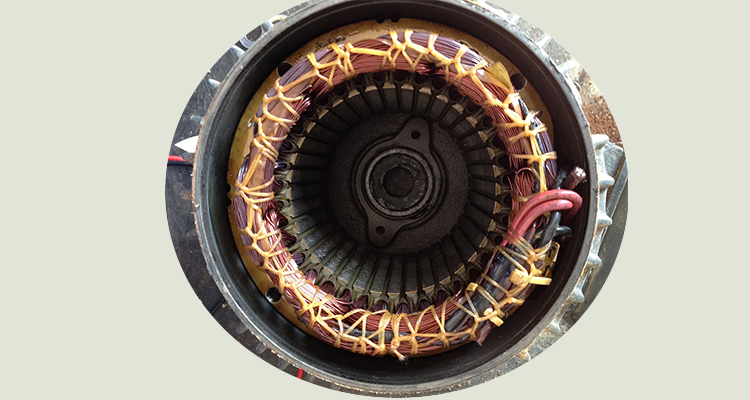

Motor as an indispensable important power provider in people's production and life, in the process of use of many electric opportunities fever is very serious phenomenon, but many times do not know how to solve, more serious is not know what is the cause of motor heating, this should be the first master in the use of the motor, let's understand why the motor fever is very serious.

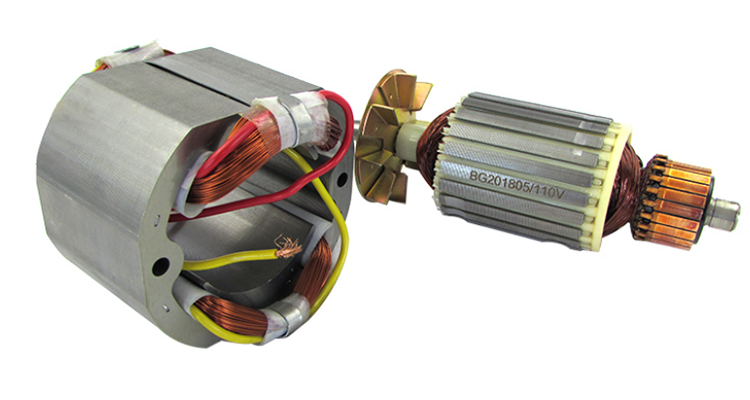

1. The air gap between the stator and rotor is very small, which easily leads to the collision between the stator and rotor.

In medium and small motors, the air gap is generally 0.2mm~1.5mm. When the air gap is large, the excitation current is high, thus affecting the power factor of the motor; the air gap is too small, the rotor may have friction or collision. Generally, due to the serious bearing tolerance and the wear and deformation of the inner hole of the end cover, the seat, end cover, rotor three different axis caused by the sweep, it is easy to make the motor heat or even burn. If the bearing wear is found, it should be replaced in time. The end cover is replaced or brushed and plated. The relatively simple treatment method is to insert the end cover.

2. The abnormal vibration or noise of the motor is easy to cause the heating of the motor.

This condition is the vibration caused by the motor itself, most are caused by poor rotor balance, poor bearing, rotation shaft bending, end cover, seat, rotor different axes, loose fasteners, or motor installation foundation, which may also be transmitted by the mechanical end, shall be excluded for the specific situation.

3. If the bearing is not working normally, the motor will be heated.

Whether the bearing works normally can be judged by hearing and temperature experience.

The bearing end detects whether the temperature is within the normal range, or the listening rod (copper rod) to contact the bearing box, if the impact sound, one or several balls may be crushed, if it is sizzling, that means that the lubricating oil of the bearing, the motor should be replaced with grease in about 3,000 hours ~5,000 hours.

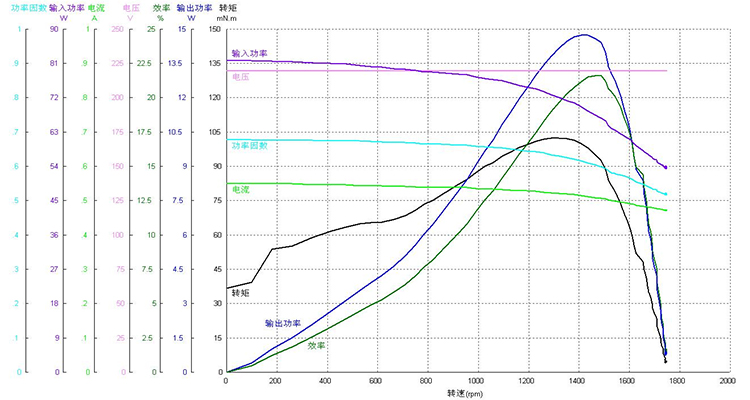

4. If the power supply voltage is too high and the excitation current increases, the motor will overheat.

Overvoltage endangers the motor insulation from being pierced. When the supply voltage is too low, the electromagnetic torque will be reduced. If the load distance is not reduced and the rotor is too low, the increased rotation rate will cause motor overload and heating, and long overload will affect the life of the motor. When the three-phase voltage is asymmetric, that is, when the one-phase voltage is high or low, it will cause a certain phase current is too large, the motor to heat, and the rotation distance reduction will sound "buzzing", which will damage the winding for a long time.

In short, whether excessive voltage, too low, or voltage asymmetry will increase the current, the motor heat and damage the motor. Therefore, according to the national standards, the motor supply voltage change should not exceed 5% of the rated ±, and the motor output power can be kept rated. The motor supply voltage shall not exceed 10% of the rated ±, and the difference between the three-phase supply voltage shall not exceed 5% of the rated ±.

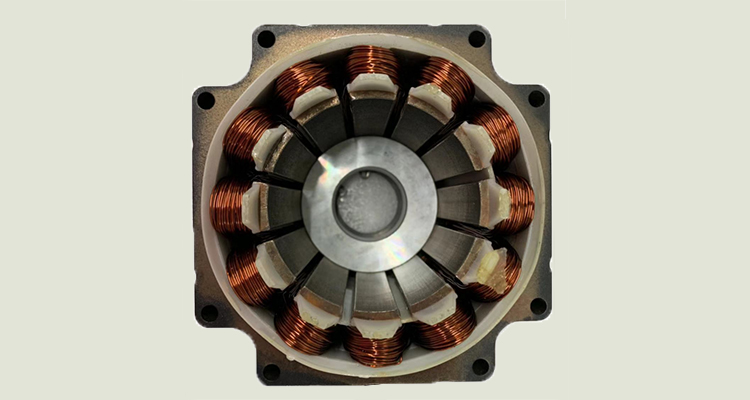

5. Winding short circuit, turn to turn short circuit, phase to phase short circuit and winding open circuit.

After the insulation between the two adjacent conductors in the winding is damaged, the two conductors collide, called the winding short circuit. A winding short circuit occurring in the same winding is called an inter-turn short circuit. A winding short circuit occurring between the two-phase windings is called an alternate short circuit. Whether that kind, it will increase a certain phase or two-phase current, causing local heating and damage to the motor. Winding open circuit is a fault caused by the breaking or burning of the stator or rotor winding of the motor. Either the winding short circuit or open circuit may cause heat or even burn of the motor. Therefore, the processing must be stopped immediately after this occurs.

6. The leakage of materials into the motor reduces the insulation of the motor and the allowable temperature rise of the motor.

Solid material or dust entering the motor from the junction box will reach the air gap between the motor stator and rotor, causing the motor to sweep until the motor winding insulation is worn out and the motor is damaged or scrapped. If the liquid and gas medium leaks into the motor, it will directly cause the motor insulation to decline and trip. General liquid and gas leakage has the following manifestations:

The leak of various containers and delivery pipes, pump body seal leakage, flushing equipment, and ground;

Enter the motor from the gap in the front-end bearing box;

The oil seal such as the reducer connected to the motor is worn, and the mechanical lubricating oil enters along the motor shaft. After the accumulation of the motor, the motor insulation paint is dissolved to gradually reduce the insulation performance of the motor.

7. Almost half of the motor burning is caused by the motor phase missing operation.

Lack of phase often causes the motor can to operate or slow after starting, or the weak turning current increases the "buzzing" sound. If the shaft load does not change, the motor is in a severe overload state and the stator current will be rated 2 times or higher. The motor will heat or even burn down in a short time. The main causes of phase operation are as follows:

One phase power failure due to other equipment failures on the power line, and the other three-phase equipment connected to the line will be out of phase operation.

A circuit breaker or contactor causes phase deficiency due to partial voltage burning or poor contact.

The motor is line due to aging, wear, and other reasons.

Motor one phase winding open circuit or one connector in the terminal box.

8. Other non-mechanical and electrical fault causes.

Motor temperature increase caused by other non-mechanical and electrical failure may also cause motor failure when serious. If the ambient temperature is high, the motor lacks a fan, the fan is incomplete, or the fan hood. In this case, forced cooling must ensure ventilation or replacement of air blades, etc., otherwise, the normal operation of the motor cannot be guaranteed.

To sum up, in order to adopt the correct method, it is necessary to be familiar with the characteristics and causes of the common motor faults, grasp the key factors, and make regular inspections and maintenance. This way to take fewer detours, save time, as soon as possible troubleshooting, make the motor in a normal operation state. Thus to ensure the normal production of the workshop.

BACK

BACK