Model Number: BG AC9540

Range of Power: 800-1200W

Range of Voltage:110-240VDC

Range of Rated Speed: 4000-15000rpm

Range of Rated Torque: 0.5-1N.m

Lifespan: 1000Hours

Model Number: BG AC65118

Range of Power: 100-300W

Range of Voltage:110-240VDC

Range of Rated Speed: 4000-15000rpm

Range of Rated Torque: 0.1-0.3N.m

Lifespan: 1200Hours

Model Number: BG 90AC105

Range of Power: 40-60W

Range of Voltage:110-240VDC

Range of Rated Speed: 8-500rpm

Range of Rated Torque: 0.5-10N.m

Lifespan: 1200Hours

Model Number: BG AC4445

Range of Power: 15-20W

Range of Voltage:110-240VDC

Range of Rated Speed: 6000-20000rpm

Range of Rated Torque: 0.02-0.06N.m

Lifespan: 1000Hours

Model Number: BG 70AC80

Range of Power: 15W

Range of Voltage:110-240VDC

Range of Rated Speed: 1200-1450rpm

Range of Rated Torque: 0.1-0.12N.m

Lifespan: 1200Hours

Model Number: BG AC5445

Range of Power: 20-50W

Range of Voltage:110-240VDC

Range of Rated Speed: 6000-10000rpm

Range of Rated Torque: 0.03-0.08N.m

Lifespan: 1000Hours

Model Number: BG AC9338

Range of Power: 800-1200W

Range of Voltage:110-240VDC

Range of Rated Speed: 4000-15000rpm

Range of Rated Torque: 0.5-1N.m

Lifespan: 1000Hours

Model Number: BG AC9540

Range of Power: 800-1200W

Range of Voltage:110-240VDC

Range of Rated Speed: 4000-15000rpm

Range of Rated Torque: 0.5-1N.m

Lifespan: 1000Hours

Model Number: BG AC02

Range of Power: 35-40W

Range of Voltage:110-240VDC

Range of Rated Speed: 6000-10000rpm

Range of Rated Torque: 0.06-0.08N.m

Lifespan: 1200Hours

Model Number: BG AC01

Range of Power: 15-20W

Range of Voltage:110-240VDC

Range of Rated Speed: 6000-12000rpm

Range of Rated Torque: 0.02-0.04N.m

Lifespan: 1200Hours

Model Number: BG AC9538

Range of Power: 800-1200W

Range of Voltage:110-240VDC

Range of Rated Speed: 4000-15000rpm

Range of Rated Torque: 0.5-1N.m

Lifespan: 1000Hours

Model Number: BG AC7630

Range of Power: 300-500W

Range of Voltage:110-240VDC

Range of Rated Speed: 4000-15000rpm

Range of Rated Torque: 0.29-0.48N.m

Lifespan: 1000Hours

Model Number: BG AC9538

Range of Power: 800-1200W

Range of Voltage:110-240VDC

Range of Rated Speed: 4000-15000rpm

Range of Rated Torque: 0.5-2N.m

Lifespan: 1200Hours

Model Number: BG AC7630

Range of Power: 300-500W

Range of Voltage:110-240VDC

Range of Rated Speed: 4000-15000rpm

Range of Rated Torque: 0.29-0.48N.m

Lifespan: 1000Hours

Model Number: BG AC6325

Range of Power: 200-400W

Range of Voltage:110-240VDC

Range of Rated Speed: 4000-15000rpm

Range of Rated Torque: 0.1-0.38N.m

Lifespan: 1000Hours

Model Number: BG AC7630

Range of Power: 300-500W

Range of Voltage:110-220VDC

Range of Rated Speed: 4000-15000rpm

Range of Rated Torque: 0.29-0.48N.m

Lifespan: 1000Hours

Because of its versatility and high efficiency, the universal motor has a wide range of application cases in life, such as washing machines, juicers, electric fans, window regulators, compressors, etc., all of which are inseparable from the operation of the universal motor. You may think that there are so many types of motors, but why only universal motors are so widely used and can be seen everywhere in daily life.

This is a good question, mainly due to the high adaptability of universal purpose motors, their compatibility with a wide range of power supplies, their ability to support different load conditions, their use of durable materials and precision design, and their ability to maintain long-term stable operation in different environments, making them widely used in domestic and industrial environments.

Read this article in detail, you will learn what a universal motor is, the structure of a universal motor and how they work under different currents, and other related knowledge, hoping to help you make more accurate judgments and choices.

A universal motor is a motor that can work normally in both alternating current (AC) and direct current (DC) environments, and its structure and performance characteristics determine its high flexibility and wide application.

The principle of universal motors is based on electromagnetic induction. The electromagnetic field interaction between the rotor and stator creates a torque that drives the machinery to rotate. Whether AC or DC power supplies are used, the current path and magnetic field strength can be adjusted to suit different power supply methods.

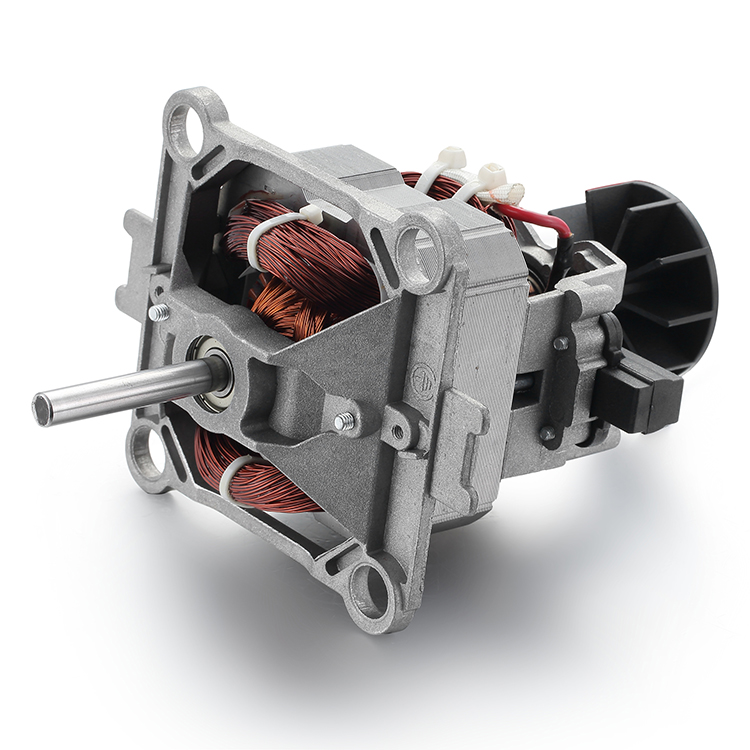

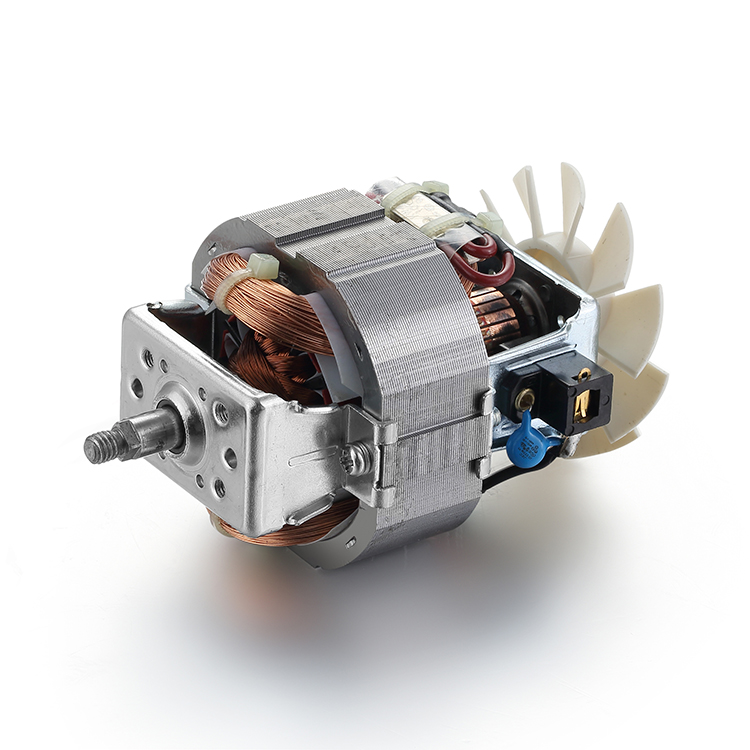

Main components:

· Stator: Consists of coil windings and an iron core that generates a magnetic field.

· Rotor: Usually made of wound or conductive material, which interacts with the stator magnetic field to achieve rotation.

· Brushes and commutators: to ensure the commutation of DC power supply to ensure continuous operation.

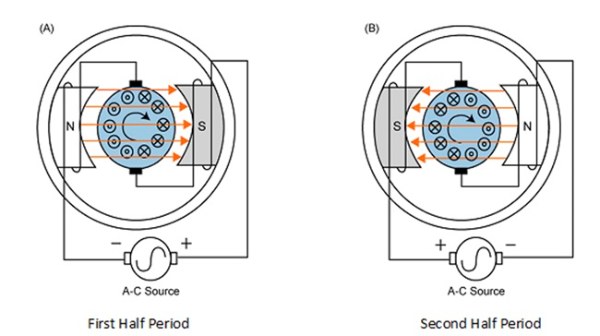

Universal motors have a wide range of applicability because they are compatible with alternating current (AC) and direct current (DC) power supply. It operates in two current modes as follows:

In DC power supply mode, the current of the universal motor enters the rotor windings through the brushes and commutators, forming a magnetic field that interacts with the magnetic field of the stator and drives the rotor to rotate.

1、Maintenance of current direction: The commutator periodically changes the direction of the current in the rotor windings to ensure that the direction of the magnetic field always pushes the rotor to rotate in a single direction.

2、Running characteristics: When DC power supply, the universal motor has a more stable speed control ability, which is suitable for application scenarios with high speed requirements.

In AC power mode, the direction and magnitude of the current change periodically with time, but due to the action of brushes and commutators, the direction of the current in the rotor windings is automatically adjusted to ensure that the direction of the magnetic field is consistent, so that the rotor continues to rotate.

1、Adaptability of current switching: The commutator of the universal purpose motor automatically processes the positive and negative half-cycle switching of the alternating current and adjusts it to the directional current that suits the winding.

2、Running characteristics: Under AC power supply, the universal motor is easy to adapt to the input of different frequencies and voltages, and is suitable for a wide range of industrial and household equipment.

1、Efficiency: DC mode is generally more efficient than AC power because of its lower energy loss.

2、Speed control: In DC mode, the voltage or current can be adjusted to achieve precise speed control, while in AC mode, the speed control depends on the input frequency.

3、Power Adaptability: General purpose motors often use AC mode in high-power applications, while DC mode is more commonly used in small portable devices.

The dual-mode adaptability of general-purpose motors allows them to be used in a wide range of applications, such as household appliances, portable equipment, and industrial machinery.

Universal motors are popular in both domestic and industrial sectors due to their wide range of adaptability and reliability. Here are the main features of the universal motor:

Dual power supply compatibility

1、Able to work under direct current (DC) and alternating current (AC), without replacing the motor to adapt to different power supply environments.

2、This feature makes it effective in both portable devices (e.g. DC power supply) and industrial equipment (e.g. AC power supply).

High speed performance

1、Speeds up to 10,000 RPM or higher are suitable for equipment that requires high-speed operation, such as blenders, vacuum cleaners, etc.

2、At the same time, the speed can be adjusted by voltage or frequency to achieve flexible speed control.

High power density

1、Provides high power output in a compact design.

2、Meets the requirements for miniaturized devices and high power requirements, such as hand tools or household equipment.

Simple structure and easy maintenance

1、Designed with carbon brushes and commutators, the structure is compact and easy to disassemble and replace.

2、Durable parts, long service life and low maintenance costs.

Adapt to a variety of application scenarios

1、Able to handle different load conditions, such as light and heavy duty working environments.

2、Suitable for household, industrial, medical equipment and other fields.

Cost-effective

1、Low production costs and excellent performance, especially suitable for large-scale application scenarios such as household appliances and industrial drives.

Flexible customization capabilities

1、By adjusting the motor winding, brush material, housing design, etc., it can adapt to the needs of different customers.

2、BG Motor offers a full range of customization services from power, speed to form factor to meet the requirements of specific application scenarios.

Summary

Universal motors have become a widely used motor type with their high compatibility, high performance and high cost performance, providing users with reliable power solutions and adapting to a variety of complex working environments.

BG Motor has rich experience in the production of universal purpose motors and strong R&D capabilities, and is committed to providing customers with high-performance, high-quality motor solutions. Here are the advantages of its expertise in the field of general motors:

Profound R&D strength

1、Professional team: composed of electrical engineers with more than 30 years of industry experience, covering the fields of electromagnetic, structural and mechanical design.

2、Advanced software support: Proficient in the use of ANSYS, JMAG, MotorCAD and other professional simulation tools to ensure the optimal performance and efficiency of general-purpose motors.

3、Technological innovation: A number of patents have been applied for in total, and continuous breakthroughs have been made in high speed, high torque and high reliability.

1、Provide comprehensive customized services from motor size, power to running speed to meet the diverse needs of customers.

2、Parameter range:

(1).Power range: 10W-1200W

(2).Voltage range: AC 110V-220V

(3).Speed range: 4000-15000 RPM

(4).Protection level: up to IP68

3、Component support: equipped with planetary gearboxes, electromagnetic compatibility components, overheat protectors, etc., to meet complex application scenarios.

1、Automated production line: The 12,000 square meter factory is equipped with fully automated equipment, which greatly improves production efficiency and reduces costs.

2、High-precision testing equipment: comprehensive testing of motor performance, vibration, noise, etc., to ensure that the quality is up to standard.

3、Strict quality control: Each motor has passed the 99.99% pass rate test, with detailed test report and performance curve.

1、Use lead-free, harmless raw materials, products in line with CE, RoHS and other international certification standards.

2、Equipped with environmentally friendly equipment, optimize the production process, and reduce the impact on the environment.

1、Export experience: The products are widely sold to the United States, Germany, Italy and other developed countries, and the customers cover many industry leaders.

2、Reputation accumulation: With high performance and excellent service to win the trust of customers, to become a high-quality supplier in the field of global general motor manufacturing.