BG MOTOR

Model Number: BG 63ZYT-30k

Range of Power: 52-125W

Range of Voltage:12-110VDC

Range of Rated Speed: 1500-5000rpm

Range of Rated Torque: 0.15-0.4N.m

Lifespan: 1000Hours

Model Number: BG 800

Range of Power: 800-3000W

Range of Voltage:36-72VDC

Range of Rated Speed: 3000-5000rpm

Range of Rated Torque: 2.2-5.4N.m

Lifespan: 5000-20000Hours

Model Number: BG60

Range of Power: 500W-1600W

Range of Voltage: 230V 50/60Hz

Max Air Flow: 145m³/h

Maximum Vacuum Presure: 18Kpa

Weight: 2.6kg

Fan System:Tangential By Pass

Application:Fume/Smoke extraction、Speayer、Dental equipment、Care equipment、Laser machine、Sterilization equipment

Model Number:BG154

Range of Power:1300W

Range of Voltage:220/380V 50/60Hz

Max Air Flow: 1800m³/h

Maximum Vacuum Presure: 4.5Kpa

Weight: 11.5kg

Application: 11Fume/Smoke extraction、Laser machine

We have various connecters.

We can provide customized requirements.

Two channel quadrature TTL compatible outputs

96 ~ 1250 cycles per resolution (CPR)

Widely operating environment temperature from -40℃ ~ 85℃

Intelligent mounting design

Compact size appearance

Cost effectively

Single 5V DC supply

RoHS compatible

Model Number:BL4815L Brushless Motor Drive

Output current: 15-35A

Range of Voltage:24-60VDC

Range of Rated Speed: 3000-20000rpm

Size:/

Lifespan:/

Model Number:BL2408L Brushless Motor Drive

Output current: 8A

Range of Voltage:12-32VDC

Range of Rated Speed: 3000-20000rpm

Size:/

Lifespan:/

Model Number:BL2406 Brushless Motor Drive

Output current: 3-8A

Range of Voltage:12-24VDC

Range of Rated Speed: 150-30000rpm

Size:60*45*33 Unit MM

Lifespan:/

Model Number: BG AC9540

Range of Power: 800-1200W

Range of Voltage:110-240VDC

Range of Rated Speed: 4000-15000rpm

Range of Rated Torque: 0.5-1N.m

Lifespan: 1000Hours

Model Number: BG AC65118

Range of Power: 100-300W

Range of Voltage:110-240VDC

Range of Rated Speed: 4000-15000rpm

Range of Rated Torque: 0.1-0.3N.m

Lifespan: 1200Hours

Model Number: BG YJ6315

Range of Power: 10-75W

Range of Voltage:110-240VDC

Range of Rated Speed: 3-69rpm

Range of Rated Torque: 2.41-8N.m

Lifespan: 1000Hours

Model Number: BG YJ6126

Range of Power: 10-75W

Range of Voltage:110-240VDC

Range of Rated Speed: 3-69rpm

Range of Rated Torque: 2.41-8N.m

Lifespan: 1000Hours

Model Number: BG YJ6125

Range of Power: 10-75W

Range of Voltage:110-240VDC

Range of Rated Speed: 3-69rpm

Range of Rated Torque: 2.41-8N.m

Lifespan: 1000Hours

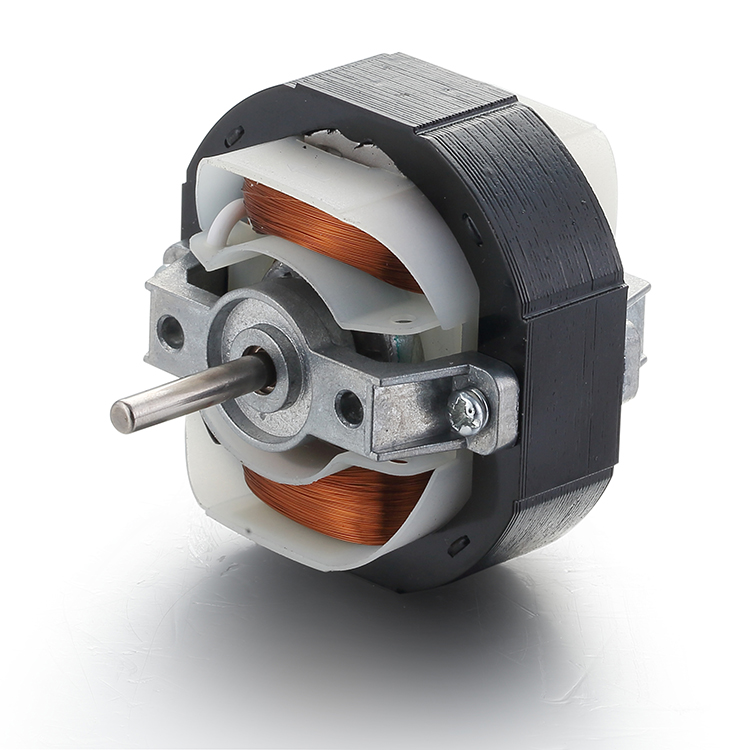

Model Number: BG YJ5812

Range of Power: 6-25W

Range of Voltage:110-240VDC

Range of Rated Speed: 1500-2600rpm

Range of Rated Torque: 0.02-0.08N.m

Lifespan: 1000Hours

What is a DC Motor?

A direct current motor is a type of electric motor that operates on direct current (DC). It converts electrical energy into mechanical energy through the interaction of magnetic fields. Here's a basic overview of how it works:

1. Basic components: DC motors typically consist of a rotor (or armature), stator, brushes, and commutator. The rotor is the rotating part of the motor, while the stator is the stationary part that generates the magnetic field. Brushes and commutators help to switch the direction of the current flowing through the rotor windings, which is essential for continuous rotation.

2.Operation: When a DC voltage is applied to the motor, the current flows through the rotor windings, generating an electromagnetic force. This force interacts with the magnetic field of the stator, causing the rotor to rotate. The commutator and brushes work together to ensure that the direction of the current in the rotor windings is constantly changing, thus maintaining continuous rotation.

3.Types of DC motors: There are many types of DC motors, including: DC brushed DC motors: use brushes and commutators to switch the direction of current. Brushless DC Motor (BLDC): Uses an electronic controller instead of brushes and commutators. With fewer friction parts, they tend to be more efficient and last longer. As well as the DC servo motor that adjusts the operating state of the motor in real time by the feedback system and the DC stepper motor that rotates the rotor step by step by sequentially excites the stator winding, so as to achieve accurate angle control.

4.Application: DC motors are widely used in various applications where speed control and smooth operation are important, such as electric vehicles, home appliances, robots and small machinery, different motors have different application places and best configurations, if needed, please contact our engineers for one-on-one communication.

5.Overall, DC motors are valued for their simplicity, ease of control, and ability to deliver a wide range of speeds and torques.

Types of DC Motors

There are several types of DC motors, each with unique advantages and applications:

It has a commutator and brushes that can switch the direction of current in the rotor windings, allowing continuous rotation. The electric energy of DC is through the brush and commutator into the armature winding, and the stator magnetic field interacts to produce torque, DC brush motor is simple and cost-effective, good control performance, smooth operation, high efficiency. However, due to the wear and tear of the brushes, it requires maintenance, and it is noisy and has a short life. It is mainly used in small electric equipment, remote control cars, electric drills, electric fans, etc.

Using an electronic controller instead of brushes and commutators, it is essentially an AC synchronous motor driven by an electronic drive with feedback control from position sensors. They offer high accuracy, high speed, high reliability, low noise, and require less maintenance, but they also increase technical complexity and manufacturing costs. It is suitable for electric vehicles, professional-grade drones, office automation equipment, medical instruments, high-speed centrifuges, and energy-saving household appliances for environmental protection purposes.

3. DC Servo Motor:

Similar to brushed or brushless motors, but equipped with a feedback system (such as an encoder) and a precision controller, it adjusts the operating status of the motor in real time through the feedback system to achieve high-precision control. It has the main advantages of high precision, high performance, and precise control of position, speed, and torque, but the system is complex and costly. It is widely used in automatic control systems, robots, aerospace.

4. DC Stepper Motor

The structure consists of multiple stator windings and segmented rotors (usually multipole). By sequentially exciteting the stator windings, the rotor rotates step by step to achieve precise angle control. Enables precise position control, good start and stop control. However, the speed range is limited, and vibration and noise may occur. It is widely used in printers, scanners, CNC machine tools, and CNC equipment.

5.Summary

-DC Brushed Motors: Ideal for cost-sensitive, easy-to-control applications.

-Brushless DC motor: suitable for high-efficiency, long-life, low-noise applications.

-DC Servo Motors: Ideal for applications that require high-precision and high-performance control.

-DC stepper motors: suitable for applications that require precise position control.

Brushed DC Motor is a traditional type of electric motor, and its main features include:

1.Structure and working principle

Stator: Usually composed of a permanent magnet or electromagnet that provides a fixed magnetic field.

Rotor: Contains brushes and commutator. The brushes are in contact with the commutator and are responsible for the commutation of the current.

Brushes and commutators: The brushes are in contact with the commutator and change the direction of the current to maintain the rotation of the rotor.

2. How it works

The electrical energy of direct current enters the armature windings through the brushes and steering gear, and interacts with the stator magnetic field to generate torque.

3. Pros & Cons

Advantages:

Simple structure: low design and manufacturing cost.

Simple control: no need for complex electronic control, easy to operate.

High starting torque: Able to provide high torque at start-up.

It is mainly manifested in wide control performance, wide speed regulation range, huge starting rotation, good vulgar performance, stable operation and high efficiency, and the application occasions are very wide from industrial to civil.

Disadvantages:

Wear and maintenance: Brushes and commutators are worn, frequent maintenance, and short life.

Low efficiency: Brush friction leads to energy loss and low operating efficiency.

Noise: Brush friction and electric sparks from the commutator can produce noise.

It is mainly manifested in high noise, short life, poor reliability, many faults, and frequent maintenance.

It is widely used in small electrical appliances, power tools, toys and other scenarios with low cost and maintenance requirements. Due to their simple design and low cost, DC brushed motors still have a place in many low-power and cost-sensitive applications.

Brushless DC motor (BLDC motor) is a new type of mechatronics motor that appears with the development of semiconductor electronic technology, which is the product of the combination of modern electronic technology (including power electronics and microelectronics technology), control theory and motor technology. It is widely used in applications that require high efficiency, long life, and low maintenance. In contrast to traditional Brushed DC motors, BLDC motors do not have brushes and commutators, which are common wear and tear parts in conventional motors.

The following is the basic concept of BLDC motors:

1.Structure and working principle

Stator: The stator of a BLDC motor is equipped with electromagnetic coils (multiphase windings) that generate a rotating magnetic field when the motor is running.

Rotor: The rotor of a BLDC motor is equipped with a permanent magnet that generates rotation through interaction with the magnetic field of the stator.

Sensors & Controllers: In order to accurately control the operation of the motor, BLDC motors are usually equipped with position sensors (e.g., Hall sensors) and electronic controllers (ECUs). The controller adjusts the current flow into the stator's coil based on the feedback from the sensor, thus controlling the speed and direction of the motor.

Therefore, a brushless DC motor is essentially an AC synchronous motor driven by an electronic inverter with feedback control from a position sensor.

2. Advantages;

High efficiency: The motor is more efficient due to less energy loss due to the absence of brushes and commutators.

Long life: Reduced wear parts, BLDC motors generally have a long service life.

Low maintenance: Brushless motors have less maintenance requirements and lower failure rates due to the absence of brushes.

High speed and high power density: Able to operate at higher speeds and provide high power output.

3. Application scenarios

Electric Vehicle: The wheels used to drive an electric vehicle.

Household appliances: such as vacuum cleaners, air conditioning fans, etc.

Drones: provide stable and efficient power.

Computer equipment: Drives for fans and other internal components.

4. Control mode:

Open-loop control: simple control method, no feedback information required. Typically used for low power and simple applications. Closed-loop control: Feedback sensors, such as Hall sensors, are used to adjust motor operating parameters in real time to ensure accurate control of speed and position.

5. Disadvantages:

Higher cost: The initial cost is usually high due to the need for electronic controllers and sensors.

Complexity: Complex control systems are required, making design and commissioning difficult.

-The rotor permanent magnet material limits the ambient temperature of the motor and is not suitable for high-temperature fields

Brushed DC motors VS brushless DC motors

Brushless DC motor (BLDC motor) and brushed DC motor (Brushed DC motor) are two common types of motors, each with its own advantages and disadvantages, suitable for different application scenarios. Here's a comparison of the two types of motors:

1. Structure:

Brushless DC motor (BLDC motor):

Stator: Equipped with an electromagnetic coil.

Rotor: Equipped with permanent magnets.

Control: The current flow into the coil is controlled by an electronic controller and a position sensor, and the speed and direction of the motor are controlled.

DC Brushed Motor:

Stator: Usually a permanent magnet or electromagnet.

Rotor: Equipped with brushes and commutator.

Control: The speed and direction of the motor are controlled by changing the direction of the current through mechanical brushes and commutators.

2. How it works

Brushless DC Motor (BLDC Motor): Uses electronic control to achieve the commutation of the motor without the need for physical brushes. The current flows through the stator coil, creating a rotating magnetic field that interacts with the permanent magnets on the rotor to create torque.

DC Brushed Motor: The commutation of the motor is realized by changing the direction of the current through the mechanical contact between the brush and the commutator. The current flows through the brushes into the rotor coil, creating a magnetic field that interacts with a permanent magnet or electromagnet on the stator.

3. Pros & Cons:

Brushless DC motor (BLDC motor):

Merit:

High efficiency: There is no friction loss of brushes, and the energy conversion efficiency is high.

Long life: no brush wear, long service life.

Low maintenance: The brushless design reduces the need for maintenance.

Low noise: Low noise during operation.

Shortcoming:

High cost: Complex electronic controllers and sensors are required, resulting in high initial costs.

Complex control: Complex electronic control systems are required.

DC Brushed Motor:

Merit:

Low cost: simple structure and low cost.

Simple control: no need for complex controllers, easy to use.

Shortcoming:

Inefficiency: Brush friction and sparks lead to energy loss.

Shorter lifespan: Brush wear leads to frequent maintenance.

High noise: The friction between the brushes and the commutator produces noise.

4. Application scenarios

Brushless DC Motors (BLDC Motors): Ideal for applications that require high efficiency, low maintenance, and high performance, such as electric vehicles, drones, high-end home appliances, and industrial automation equipment.

DC Brushed Motors: Suitable for cost-sensitive and low-maintenance applications such as small household appliances, power tools, and some low-power applications.

5. Operational characteristics

Brushless DC Motor (BLDC Motor): Provides smooth and high-precision control capable of achieving high rotational speed and high load capacity.

DC Brushed Motors: Speed and torque control is relatively simple, but performance degradation may occur at high loads or high speeds.

Application of brushless DC motor and brushed DC motor

Brushless DC motors (BLDC motors) and brushed DC motors (Brushed DC motors) perform differently in different application scenarios due to their different characteristics. Here are some of the main areas of application for each:

Brushless DC motor (BLDC motor)

1. Electric vehicles: Because of their high efficiency and long life, they are used to drive the wheels of electric vehicles and make a great contribution to environmental protection.

2. UAV: provides high power and high efficiency for driving the rotors. The motor drive controller is used to control the speed and direction of the drone to improve stability, accuracy and reliability.

3. High-end household appliances: such as "inverter" high-efficiency air conditioning fans, washing machines and vacuum cleaners, which have the advantages of energy saving and high efficiency, low noise, comfort and intelligence.

4. Industrial automation: It is used to drive robotic arms and conveyor belts in automated production lines. As well as the latest generation of elevator toothless traction machine, causing a revolutionary change in elevators.

5. Medical equipment: such as electric surgical instruments and hospital bed adjustment systems, due to their reliability and precise control capabilities.

6. Computers and office equipment: such as computer fans and printers, due to their high efficiency and low noise characteristics.

DC brushed motor

1. Household appliances: such as small electric fans, blenders, etc., because of their low cost and simple control.

2. Power tools: such as electric drills, screwdrivers, etc., because of their high starting torque and relatively low cost.

3.Toys: such as remote control cars and other electric toys because of their simple structure and cost-effective.

4. Small electric equipment: such as electric curtains and electric switches, because of its simple operation and economy.

summary

BLDC motors: for applications that require high efficiency, low maintenance and high performance.

Brushed motors: Ideal for cost-sensitive, low-maintenance applications, or applications that require high starting torque.

Which is better, DC countless motor or DC brush motor

Brushless DC motors (BLDC motors) and brushed DC motors (Brushed DC motors) have their own advantages and disadvantages, and which is better depends on the specific application needs and priorities. Here's a comprehensive comparison of these two motors to help you decide which is better for your needs:

brushless DC motor (BLDC motor):

Advantages:

High efficiency: Due to the absence of friction between brushes and commutators, BLDC motors have high energy conversion efficiency and are suitable for high-efficiency applications.

Long life: Reduced wear parts (e.g. brushes) result in a longer service life and less maintenance required.

Low Maintenance: The brushless design reduces maintenance requirements and is suitable for applications where reliability is critical.

Low noise: Low noise during operation, suitable for noise-sensitive environments.

High speed and high power density: Stable operation at higher speeds for applications that require high performance.

Applicable Scenarios:

Electric Vehicles Drones High-end household appliances (e.g., high-efficiency air conditioning fans, washing machines) Industrial automation equipment Medical equipment (e.g., electric surgical instruments) High-performance computers and office equipment

DC brushed motors

Advantages:

1.Low cost: Simple structure, low manufacturing cost, suitable for applications with limited budget.

2.Simple control: no need for complex electronic controllers, easy to operate and debug.

3.High starting torque: Able to provide high torque at start-up, suitable for applications that require high starting torque.

Applicable Scenarios:

Small household appliances (e.g. fans, blenders) Power tools (e.g. drills, screwdrivers) Toys (e.g. remote control cars, electric toys) Small electric devices (e.g. electric curtains, door locks)

Compare and summarize

If you need a high-efficiency, long-life and low-maintenance motor, e.g. for electric vehicles or high-performance industrial equipment, brushless DC motors (BLDC motors) are more suitable.

If you need a motor that is cost-effective and easy to operate, such as for small appliances or toys, a DC brush motor may be a better choice. The final choice depends on your specific needs, including budget, efficiency, longevity, maintenance requirements, and performance metrics.

How to choose brushless DC and brushed DC motors

When choosing a brushless DC motor (BLDC motor) and a brushed DC motor (Brushed DC motor), there are several key factors that can be used to make a decision:

1. Application requirements

High efficiency and long life: If you need a motor with high efficiency, long life and low maintenance, choose a brushless DC motor (BLDC motor).

Cost-sensitive and simple control: If you have a limited budget and low control complexity, choose a DC brush motor.

2. Operating environment

Noise and Vibration: In environments with strict requirements for noise and vibration, BLDC motors are generally quieter due to their brushless design.

Harsh environment: If the motor is operating in a harsh environment, the long life and low maintenance requirements of the BLDC motor may be more suitable.

3.Cost

Budget: DC brushed motors are typically less expensive and suitable for applications with limited budgets.

Long-term investment: If long-term use and maintenance costs are taken into account, BLDC motors may be more cost-effective in the long run, despite their higher initial costs.

4.Performance requirements

1.High power and high speeds: If the application requires high speeds or high power outputs, BLDC motors excel due to their high power density and efficiency.

2.Starting torque: If the application requires a high starting torque, the DC brush motor provides a higher torque during the start-up phase.

5.Control complexity

Simple control: The brush motor control system is simple, does not require complex electronic controllers, and is easy to debug and operate.

Precision control: BLDC motors require electronic controllers and sensors for applications that require precision control.

6.Maintenance:

Low maintenance requirements: BLDC motors reduce wear parts and require low maintenance, making them suitable for maintenance-intensive applications.

Regular maintenance: Brushed motors require regular maintenance due to brush wear and are suitable for applications where maintenance costs and cycles are acceptable.

7.Application examples

Brushless DC motors (BLDC motors): electric vehicles, drones, high-end household appliances, industrial automation equipment.

DC brushed motors: small household appliances (such as fans), power tools (such as electric drills), toys. Based on a comprehensive evaluation of these factors, select the motor that best suits your specific application needs.

What can be included in the motor customization program

1. Motor type customization

-Brushless DC motor (BLDC): high efficiency, long life, low noise, low maintenance.

-DC brushed motor: low cost, simple control, high starting torque.

2.Size and shape customization

Dimensions: Customize the size and shape of the motor according to the space requirements.

Installation: Different mounting options are available, such as flange mounting, bracket mounting, etc.

3. Performance parameter customization

Power and speed: Customize the power and speed of the motor according to the load requirements.

Torque: The rated torque of the motor can be customized according to the application needs.

Efficiency: Optimize the motor design to improve operational efficiency.

4. Material and structure customization

Material selection: Choose the right material to meet different environmental requirements (e.g. high temperature, corrosion, etc.).

Insulation Grade: Customize the insulation grade of the motor according to the application environment.

5. Control system customization

Controllers: Different types of controllers are available according to requirements, such as open-loop or closed-loop control.

Feedback system: Integration of different sensors (e.g. Hall sensors, encoders) for precise control.

6. Customization of electrical characteristics

- Voltage and current: The working voltage and current specifications of the motor are customized according to customer needs.

- Starting and running characteristics: Adjust the starting and running characteristics of the motor to suit the specific application.

7. Environmental adaptability customization

Protection level: Different protection levels (such as IP rating) are provided according to the application environment.

Temperature range: Motors designed to adapt to different operating temperature ranges.

8. Customization for special requirements

Noise & Vibration: Optimize the design to reduce noise and vibration.

Heat dissipation design: design a suitable heat dissipation system according to the use environment and load conditions.

9. Appearance and logo customization

- Exterior Design: Customized exterior design and color options are available.

- Brand logo: Add brand logo or mark on the motor according to customer requirements.

10. Service and Support:

Technical support: provide technical consultation, design advice and application support.

After-sales service: Provide comprehensive after-sales service, including warranty, maintenance and repair. Depending on the customer's specific needs, these customized solutions can be combined to provide the most suitable motor solution.

11. Provide data confidentiality services and confidentiality agreements with legal effect