what's app

what's appFunction:

BG Motor has a professional technical team and advanced R&D experience in vacuum cleaner manufacturing, and has a professional production line. BG production and development of vacuum cleaners mainly include BG26, BG36, BG43, BG51 and other series, in the vacuum cleaner product page has their specific data sheet and size drawing, (click the link to enter). They are mainly used in vacuum cleaners, sprayers, hand dryers, sterilizers, ventilation and smoke exhaust equipment, dental medical equipment, nursing equipment, etc. It has the characteristics of high efficiency and energy saving, adjustable speed, large vacuum, signal feedback, low noise and long life. And provide 100% calibration and factory inspection.

The main data ranges include:

Power range: 5W-20KW

Voltage range: DC6V-310V or AC110V-220V

Speed: Up to 100,000 RPM

Customizability: Shafts, mounting holes, and mounting methods can be customized according to customer requirements

Durability: Long service life and IP68 protection.

These characteristics make BG Motors' vacuum cleaner motors ideal for manufacturers looking for reliable, high-torque motors for their cleaning equipment.

Technical Features

BG Motor focuses on innovation and technological progress in the production and development of brushless vacuum cleaner motors, and is committed to providing customers with high-performance, customized motor solutions. The following are our main innovations and technical highlights in this field:

High-efficiency design

We use advanced electromagnetic design technology and professional simulation software such as ANSYS and jmag to optimize the power density and energy efficiency of the motor. With this technology, the motor can provide higher speeds at lower power consumption, improving the overall efficiency and service life of the vacuum cleaner.

Low noise and low vibration technology

BG Motor's brushless motor uses advanced balancing technology and noise reduction design, making the motor run with less than 40dB noise and vibration controlled within 6.1mm/s². This technological breakthrough allows our motor to work efficiently while remaining quiet, suitable for home or commercial environments with high noise requirements.

Long life and high reliability

We extend the service life of brushless motors through strict material selection and structural optimization. The core components of the motor are made of high-temperature and wear-resistant materials, combined with innovative heat dissipation design to ensure that the motor can maintain stable performance under high-load conditions. This design makes our motor life significantly longer than traditional motors.

Intelligent control and integrated solutions

BG Motor provides intelligent drive systems that are compatible with brushless motors and support multiple control modes (such as PWM, Hall sensor control), allowing customers to adjust the speed and power of the motor according to different application requirements. At the same time, we also provide integrated gearboxes, encoders and brake systems to provide customers with complete motor drive solutions and simplify the development and integration process for customers.

Environmentally friendly materials and energy-saving technologies

We always follow environmental standards in motor research and development, use heavy metal-free and pollution-free materials, and the motor production process has passed multiple environmental certifications such as FCC, CE, ROHS and CCC. Our brushless motors not only have high performance, but also can effectively reduce energy consumption, in line with the global trend of green energy conservation.

Through these innovations and technological advances, BG Motor is in the leading position in the research and development of brushless vacuum cleaner motors, and can provide customers with efficient and reliable motor products and customized solutions according to different needs.

Application:

In the special vacuum cleaner, it has the characteristics of high efficiency, low noise and long life, which is suitable for a variety of scenarios and can meet the needs of different equipment. The main application scenarios include:

Household vacuum cleaner: The brushless motor provides strong suction power and high efficiency for the vacuum cleaner, which is suitable for daily cleaning of the family, has the advantages of low noise and long-term use, and meets the user's needs for quiet and durability.

Industrial vacuum cleaner: suitable for factories, workshops, warehouses and other industrial environments, able to work for a long time, the high torque and high efficiency of the motor ensure that it can handle all kinds of dust and debris and adapt to complex working environments.

Intelligent robot vacuum: The high speed and low power consumption of the brushless motor make it an ideal driving choice for the robot vacuum, ensuring that the equipment can be cleaned efficiently while prolonging the battery life during operation.

Car vacuum cleaner: The brushless motor used in the portable vacuum cleaner is small in size, light in weight, and powerful enough to be suitable for cleaning in the car, ensuring that the equipment is easy to carry and operate.

Vertical vacuum cleaner: suitable for large-scale carpet cleaning, with large suction power, strong efficiency and long life.

Commercial places: For commercial vacuum equipment such as hotels, shopping malls and other places, brushless motors can provide quiet and stable performance, meet the needs of long-term and high-frequency use, and ensure efficient cleaning.

Through these application scenarios, BG Motor's brushless vacuum cleaner motors not only improve the performance of the equipment, but also significantly extend the service life of the product and reduce maintenance costs.

BG's real-life case of brushless vacuum cleaners

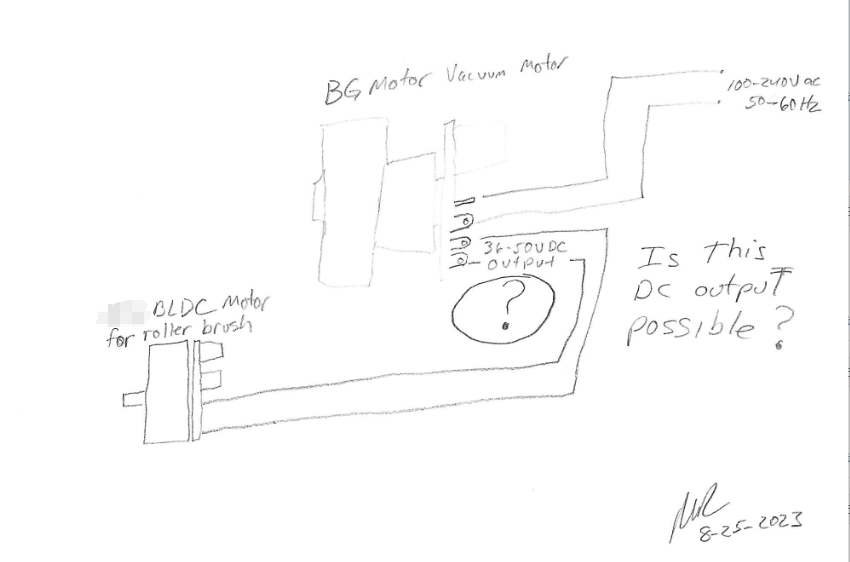

In August 2021, Mark found us through Google and sent an inquiry about a high-speed BLDC vacuum motor. After a month of exchanging 50 emails, we finally agreed on the perfect motor design. Following two rounds of sample testing over three months, everything passed with flying colors, and we moved into mass production. But that was just the beginning of our journey.

In April 2023, our colleague Anna visited the U.S. to meet with the client. They revealed a new vacuum cleaner project requiring a dual-voltage AC motor, capable of automatically switching between 110V and 230V. At first, the idea seemed impossible—creating an vacuum motor with such flexibility was unprecedented in our industry.

But Mark, ever the visionary, said, “Anna, let’s work some magic. Let’s be the first in the industry to achieve this.”

When Anna returned to China, she immediately gathered our technical team to brainstorm this challenge. After 10 days of intense research by our mechanical and electrical engineers, we realized this idea might actually be feasible.

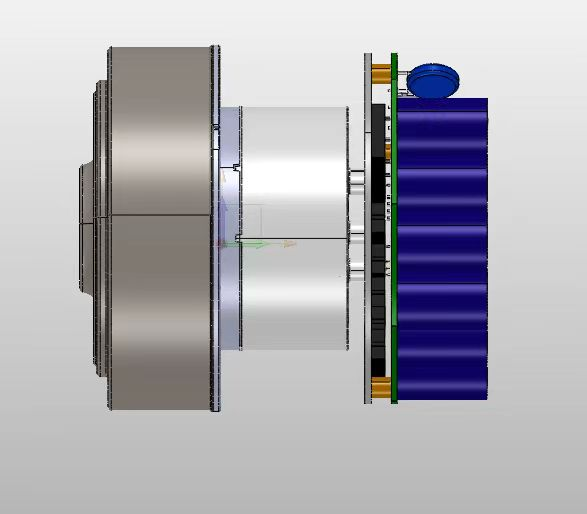

We quickly launched the project, using the client’s detailed 3D vacuum cleaner designs to tailor our motor. The dual voltage requirement, coupled with the need for overload protection and compact sizing, presented a significant challenge. But our technical and software teams collaborated closely, and after three months of relentless effort, we successfully developed the solution.

This is the spirit of BG Motor. When our clients present a challenge, we go the extra mile to meet their needs.

Trust us, BG will create unexpected miracles.

BACK

BACK