what's app

what's appIn today's rapidly evolving industries, standard motors often fail to meet the specific needs of specialized applications. This can lead to inefficiencies, higher costs, and poor performance. Customized motors provide the solution, offering the precision, power, and adaptability required to keep operations running smoothly. Read on to discover how customized motors can help optimize your operations.

BG Motor specializes in developing and manufacturing customized motors tailored to specific applications. Our advanced R&D capabilities ensure that each motor meets the precise demands of your project, offering unmatched performance and reliability.

When selecting the right motor for unique applications, it's essential to understand the different options available. Customized motors can optimize performance by adjusting size, voltage, noise levels, and more. In this article, we will explore the common applications of customized motors, what can be customized, and the advantages that come with tailored solutions. Read on to learn more.

Customized motors are crucial in various industries where standard solutions cannot meet the specific needs of the application. These motors are widely used in robotics, medical devices, automation systems, household appliances, and electric vehicles, among others.

For example, in the robotics industry, custom BLDC motors are essential for ensuring precise movements and reliable operation of robotic arms and automated systems. Similarly, in medical devices, motors need to meet stringent standards for size, torque, and noise levels, particularly in medical centrifuges or surgical instruments, where high precision is non-negotiable. In electric vehicles, customized motors provide efficient power transmission that matches the vehicle’s design and energy requirements.

Tailoring motors to these specific needs ensures optimal functionality, energy efficiency, and reliability, helping manufacturers and industries meet increasingly complex demands.

When customizing motors, various aspects can be adjusted to better fit the application’s requirements. Size, torque, voltage, bearings, noise levels, and protection features are among the most commonly customized items.

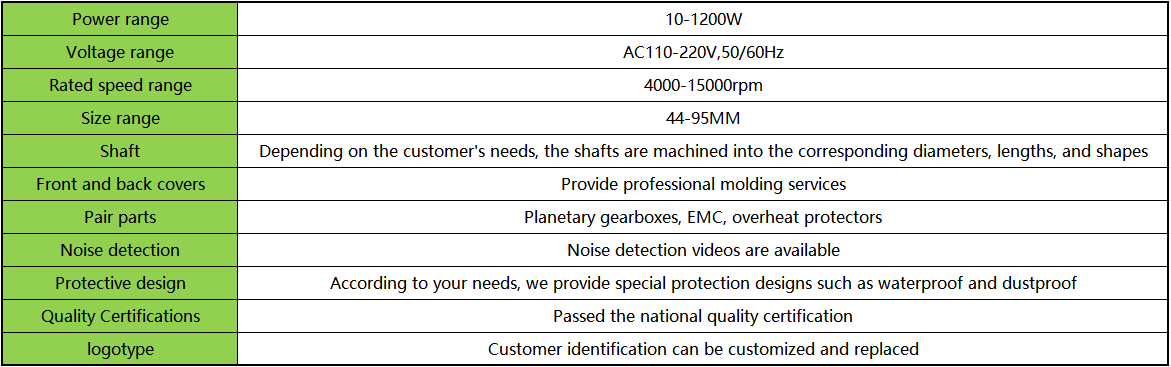

(The above is the customized data of our AC motor, please refer to the customized webpage for brushless motor and brushed motor)

Size: Motors may need to be smaller or larger to fit in constrained spaces or to provide higher output for demanding applications. Custom motors can be precisely sized to fit the design and performance parameters.

Torque: Customized motors can be engineered to deliver specific torque values, ensuring optimal performance in tasks like lifting, rotating, or moving heavy loads in automation or robotics.

Voltage and Power: Different applications require motors to operate at various voltages. Customized motors can be designed to handle the voltage range and energy output needed for specific systems.

Noise Levels: In industries such as healthcare, where noise can be disruptive, low-noise motors are often crucial. Customized motors can be designed to operate at the lowest possible decibel levels, ensuring that operations remain quiet and efficient.

Protection: Customized motors may be fitted with specialized protection features such as

IP ratings, overload protection, or thermal protection to ensure they operate safely in extreme conditions, such as high humidity or exposure to dust and debris.

Advantages of Customized Motors

The primary advantage of customized motors is their ability to meet specific performance requirements. Standard motors may not offer the flexibility needed for certain applications, leading to inefficiency, downtime, or even equipment failure. Customized motors provide several benefits:

Tailored Performance: Custom motors are designed to match the precise needs of the application, whether it’s for higher efficiency, more torque, or quieter operation.

Space Efficiency: Custom motors can be made to fit in tight spaces, where standard motors might be too bulky or inefficient.

Enhanced Durability and Reliability: By tailoring the materials and construction, custom motors are made to withstand the unique demands of the environment, ensuring long-term performance and minimal maintenance.

Energy Efficiency: Custom motors can be designed to consume less energy while providing the necessary performance, reducing operational costs in the long run.

Reduced Downtime: With the right motor tailored to the application, you can minimize breakdowns and improve the overall reliability of your equipment.

Custom motors provide a competitive edge by allowing companies to optimize their processes, improve productivity, and reduce operational costs.

At BG Motor, we are committed to providing high-quality customized motors that meet the most rigorous standards. Our motors are manufactured using state-of-the-art materials and advanced production techniques to ensure that they deliver consistent performance and durability.

We implement strict quality control measures throughout the production process, including testing each motor for performance, safety, and reliability. Our motors are certified with CE, CCC, and other relevant certifications, ensuring they meet global quality standards. Additionally, our experienced engineers work closely with customers to ensure that every motor meets the exact specifications for the application, offering both superior performance and long-lasting reliability.

Customized motors are essential for ensuring optimal performance, energy efficiency, and reliability in specialized applications. By choosing a customized motor solution, companies can improve productivity, reduce costs, and enhance the longevity of their systems. At BG Motor, we provide tailored solutions to meet your exact motor requirements, backed by rigorous quality assurance and advanced R&D capabilities.

Therefore, if you have any needs, please contact us in time, we will have professional engineers to communicate with you in detail.

BACK

BACK