Client: Mr. Xue

Country: China

Industry: Sewing machine

Cooperation time: from 1995 to now

In the early 90's, with the reform and opening up of China's textile industry, there was an urgent need for a new type of fabric cutting machine to improve production efficiency, then Mr. Xue approached us to develop and produce a motor with long life and low noise. They had previously cooperate with several suppliers, but the immaturity of the technology had always led to problems such as motors that burned easily, short life, high noise and high current.

With such a high speed,16000rpm,as machine will be used by manual. The body temperature of the motor should not exceed 60 degrees Celsius and should not get hot

heat-up problem: With such a high speed,16000rpm,as machine will be used by manual.The body temperature of the motor should not exceed 60 degrees Celsius and should not get hot

low noise: For the worker’s healthy,as they will be close to use the machine, the machine can not make too much sharp and harsh noise.

lifespan:As a kind of industrial machine, it is bound to have a long lifespan and cannot be easily burned up.

low current:In order to be more energy efficient, the current is as small as possible while the power meets the requirements

no vibration: As the machine will be continuously work for a long time and Integrity of fabric cutting.The motor must run smoothly with no vibration.

In the early stage of product development, our founder and technical engineers spent more than one month in the customer's factory to study the working principle and requirements of the product, and solved the problem faced by the customer by adopting a new approach after constantly revising the design in response to the requirements raised by the customer

Heat-up problem

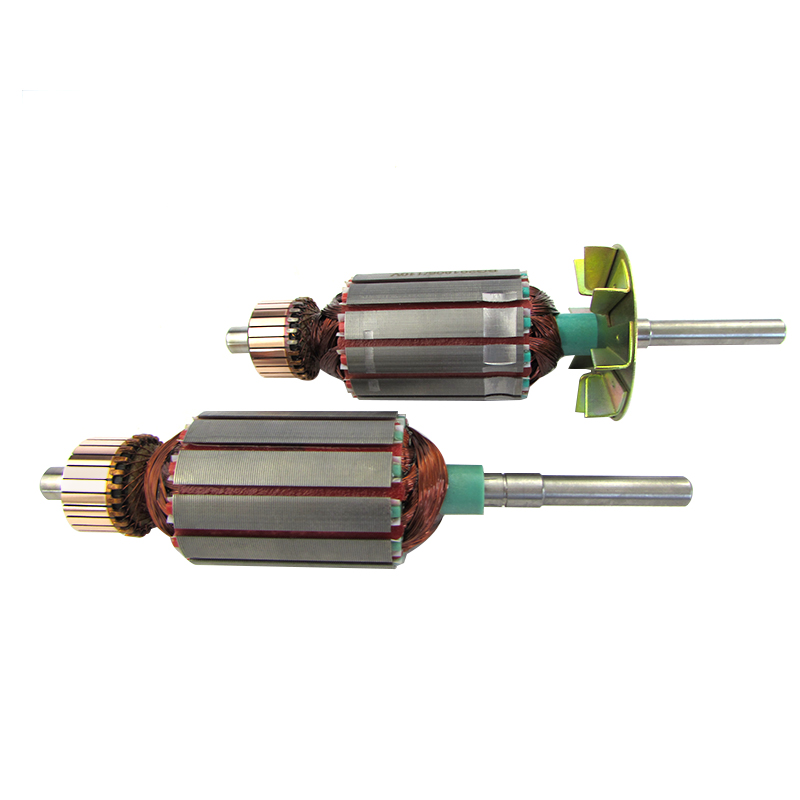

In order to make the motor's speed at a very high situation, not hot and low temperature, our engineers optimize the number of rotor slots and the shape of the airfoil by increasing the number of slots by half on the basis of the original, and the use of higher insulation grade H or higher raw materials, airfoil using the principle of mechanics, more can enhance the heat dissipation effect of the motor.

Low noise

By making the motor's straight groove into the form of oblique groove and the commutator using a severe process in the processing of the turning process, our engineers have completely reduced the noise of the motor by several dB.

Lifespan

For high speed AC motors, in addition to the rotor and stator, the main thing is the cooperation between carbon brushes and commutator. Our team of engineers has gone through thousands of experiments and verifications to finally ensure that the motor can be fully used for more than 2000 hours; usually the life span of this type of motor is around 1500 hours.

Low current

In order to save energy, our engineers use the design principle of odd number of winding turns, which distributes the rotor and stator winding turns rationally and combines the principle of multi-pole number. Thus, the efficiency of use is increased and the current is reduced as much as possible.

No vibration

In actual use, the motor is required to drive the blade to run, if the shaft has a slight wobble, it will lead to the blade and fabric in the process of cutting, there is an untidy situation, so our engineers in the design, extra more enhance the process of adjusting the shaft level, as well as the motor in the balance, we use a strict 20mg requirements, completely help customers to solve this problem.

Our customers are very satisfied when they receive our motors. They put the motors into the market with their products and got very good feedback from the market. We have developed 15 more motors of this type in succession. Now this customer is a leading manufacturer in the fabric cutting machine industry in China. Cooperation from 1995 to now, both our customer and us believe that we will have more 30 years of cooperation . AS motor is a very important component of machine, just like the human heart. We will insist on providing our customers with the highest quality motors to help their business.

In my opinion, the director manager of BG and their engineers are very professional in the motor industry. Their quality control is very good, we purchase millions dollars of motors from them every year, almost without any quality problems; and they also give us some guidance in our product design, BG Motor is our reliable and trustworthy manufacturer, we believe we will keep working together in the next 30years even longer!

--Mr.Xue(CEO)

BACK

BACK

BG Motor insisting on producing the best quality motors for our customers.