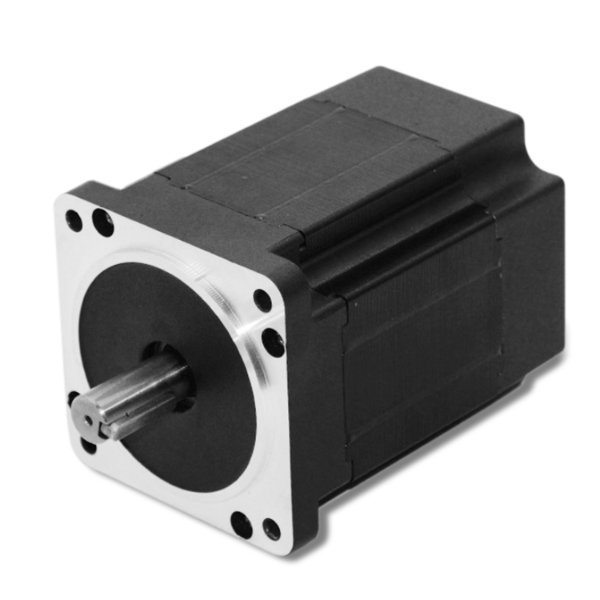

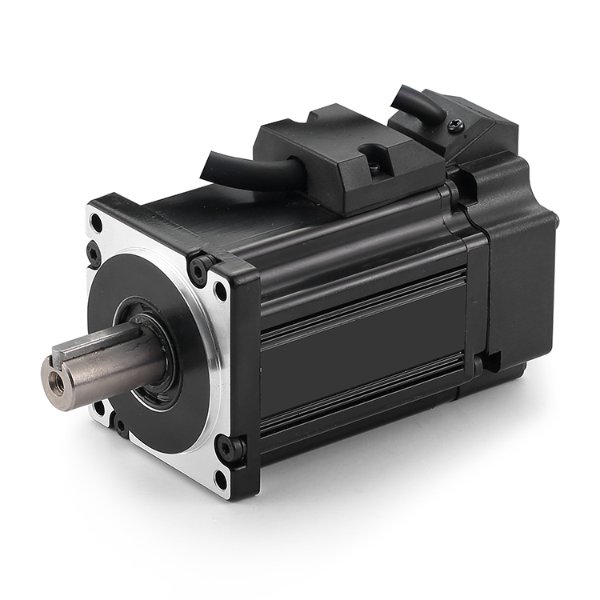

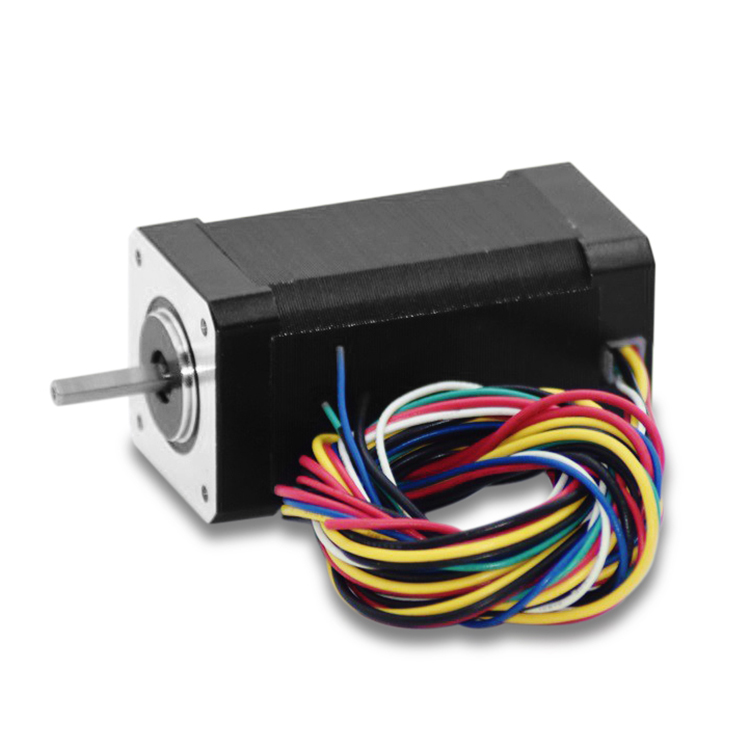

Description

| Environmental Conditons | —20℃~50℃ | Number of Phases | 3 |

| Rotation Direction | CW/CCW | Insulation Class | B-H |

| Noise | ≤60dB | Protection Class | IP40 |

| Work Condition | S1.S2.S3 |

Advantages

- 01High Efficiency

Due to the brushless design that eliminates frictional losses between the brushes and the commutator, BLDC motors are generally more efficient than brushed motors, especially under high load conditions.

- 02Low Maintenance

Since there are no brushes, BLDC motors do not need to be replaced regularly, reducing maintenance costs and time.

- 03High Reliability And Long Life

The brushless design reduces mechanical wear and improves the reliability and service life of the motor

- 04High Power Density

BLDC motors can provide high power output in a small volume, which is suitable for application scenarios where space is limited.

05Precise speed and position control

Due to the electronic commutation mode of BLDC motors, precise speed and position control can be realized, which is suitable for applications that require high-precision control.

06Quiet operation

The brushless motor operates with low noise because there is no frictional noise of the brushes and commutators.

07High speed

BLDC motor can achieve high speed, suitable for high-speed applications, such as power tools and high-speed rotating equipment.

08Better thermal management

The stator of brushless motors is usually surrounded by the rotor, which has a better heat dissipation effect and helps to improve the efficiency and life of the motor.

Motor Technical Data

| Electrical Specifications | |||||||||

| Model | RATED LOAD | NO LOAD | STALL | ||||||

| Voltage | Power | Speed | Torque | Current | Speed | Current | Torque | Current | |

| V | W | rpm | N.m | A | rpm | A | N.m | A | |

| BG 86BL80 | 48 | 314 | 3000 | 1 | 8.5 | 4000 | 1 | 3 | 25.5 |

| BG 86BL90 | 48 | 400 | 3000 | 1.27 | 10.8 | 4000 | 1.5 | 3.81 | 32.4 |

| BG 86BL105 | 48 | 565 | 3000 | 1.8 | 14.8 | 4000 | 1.75 | 5.4 | 44.4 |

| BG 86BL130 | 310 | 785 | 3000 | 2.5 | 3.3 | 4000 | 0.7 | 7.5 | 9.9 |

| We can also customize products according to customer requirements. | |||||||||

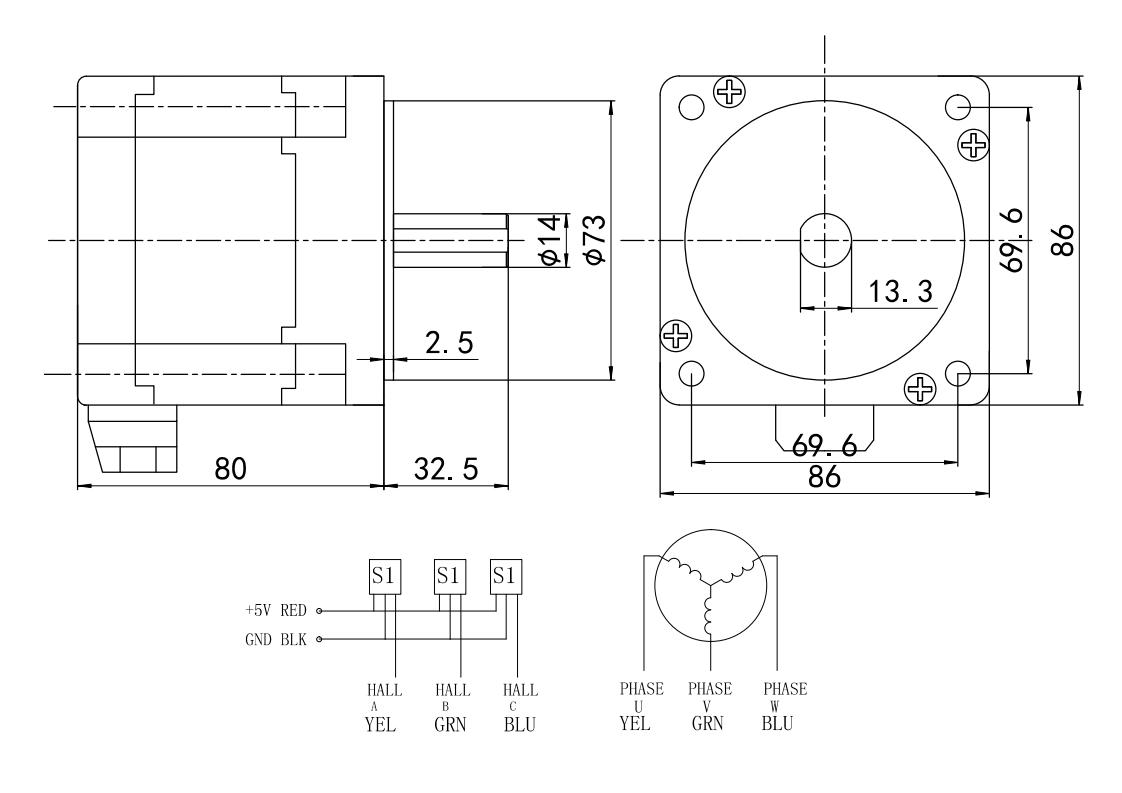

Mechanical Dimensions

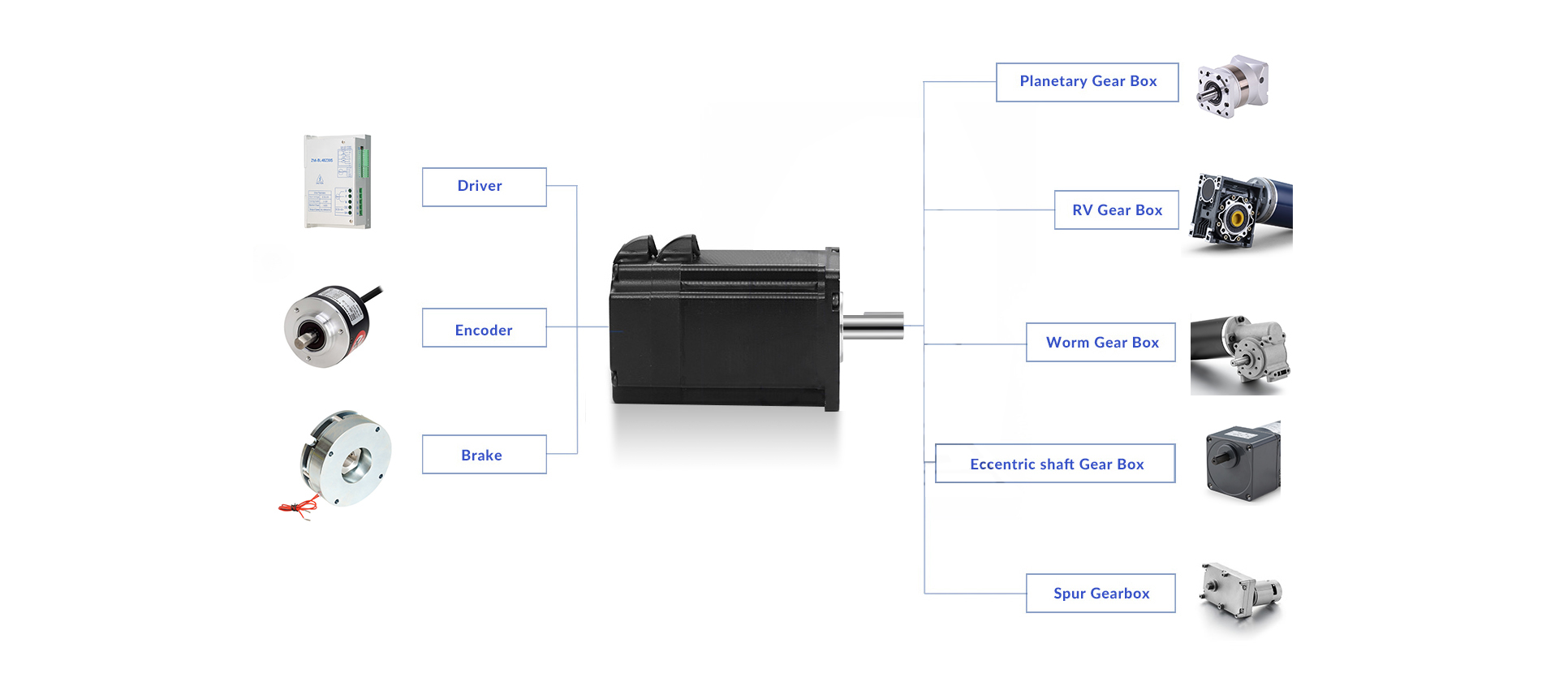

Customizable solutions

Can provide custom voltage, electrical performance, circuit, etc.

And shaft, installation flange, lead wire, high-temperature class, drive, etc.

If you have any other needs, please contact our sales engineers

Parts

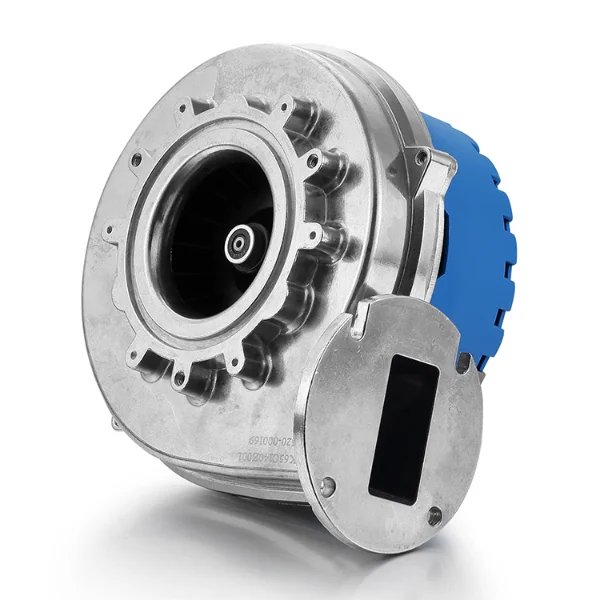

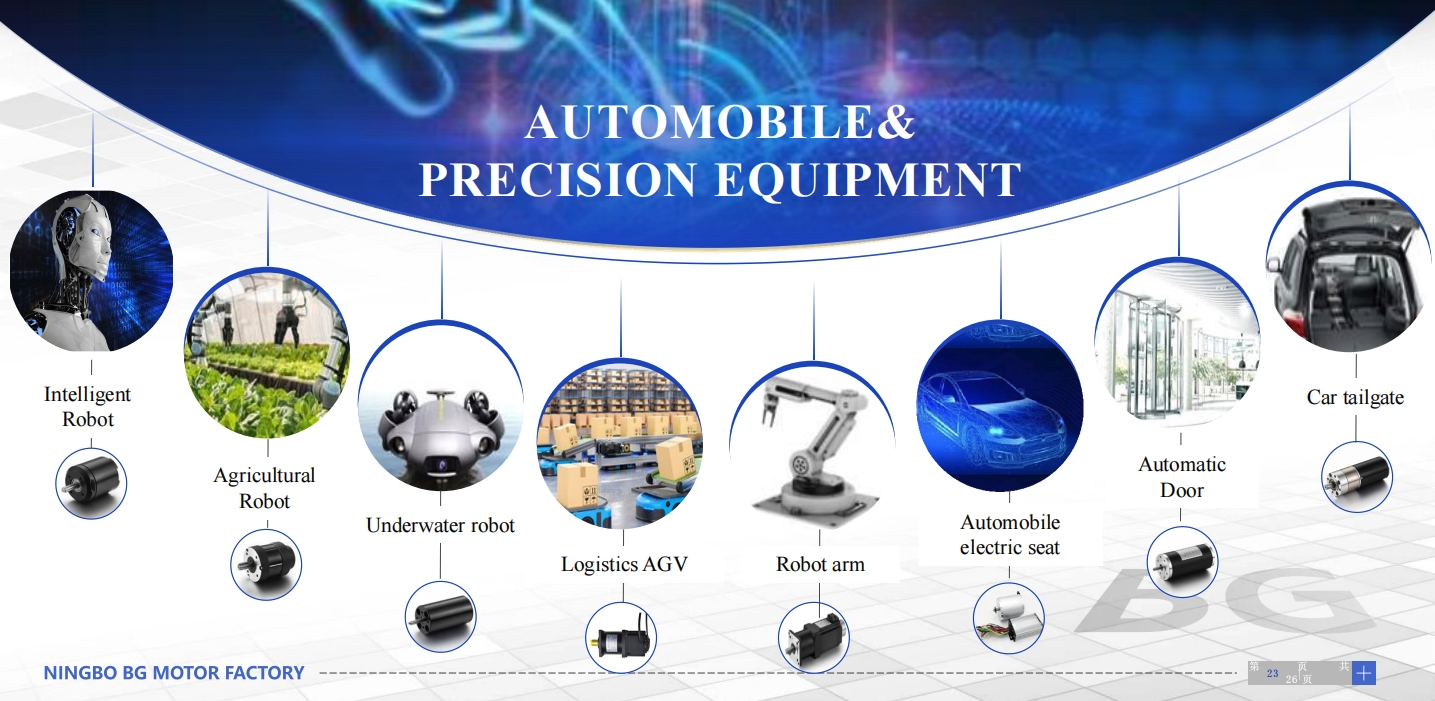

Applications

Motor Selection Details

01Application requirements:

Specific application scenarios (e.g., industrial robots, drones, power tools, AGVs, medical equipment, etc.)

Required operating environment (e.g., temperature range, humidity, dust and water resistance, etc.)02Motor Specifications:

Rated voltage and currentRated power and peak poweSpeed range (RPM, rpm)Torque requirements (rated torque and maximum torque)Efficiency requirements

03

Dimensions & Weight:

Dimensions (diameter, length, etc.)Weight Limit

04Control Requirements

Control type (e.g. open-loop control, closed-loop control)、Type of sensor required (e.g. Hall sensor, encoder)

05Connection & Installation:

Type and size of shaft、Installation method (flange mounting, base mounting, etc.Wiring method and connector type

06Power requirements

Power supply type (DC power, battery, AC power, etc.)Rated voltage range and allowable voltage fluctuations

07Environmental conditions:

Ingress protection (e.g. IP rating)、Operating temperature range、Operating temperature range、Operating temperature range

08Other special requirements:

Noise level (for noise-sensitive applications, choose a low-noise, low-vibration motor)

Electromagnetic Compatibility (EMC)、Lifetime and reliability requirements