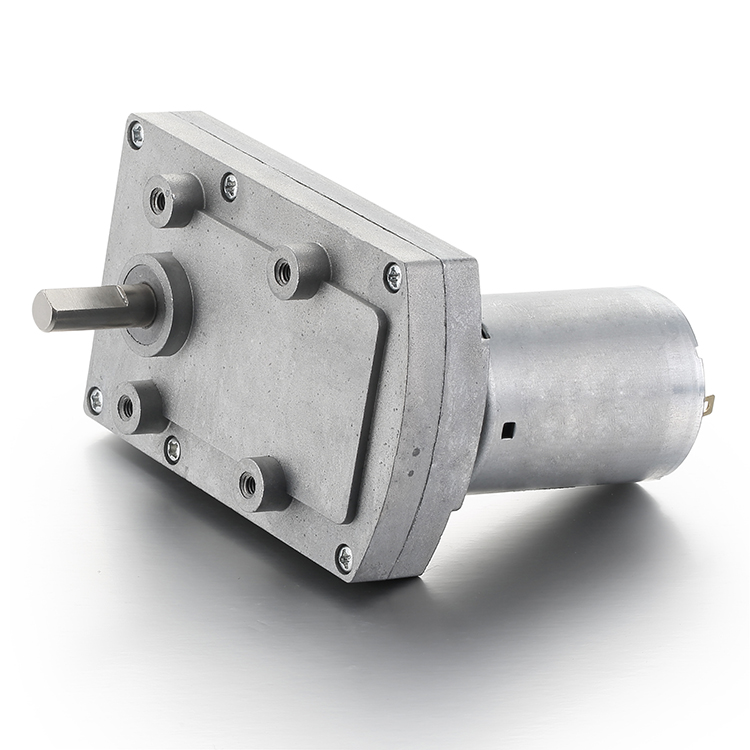

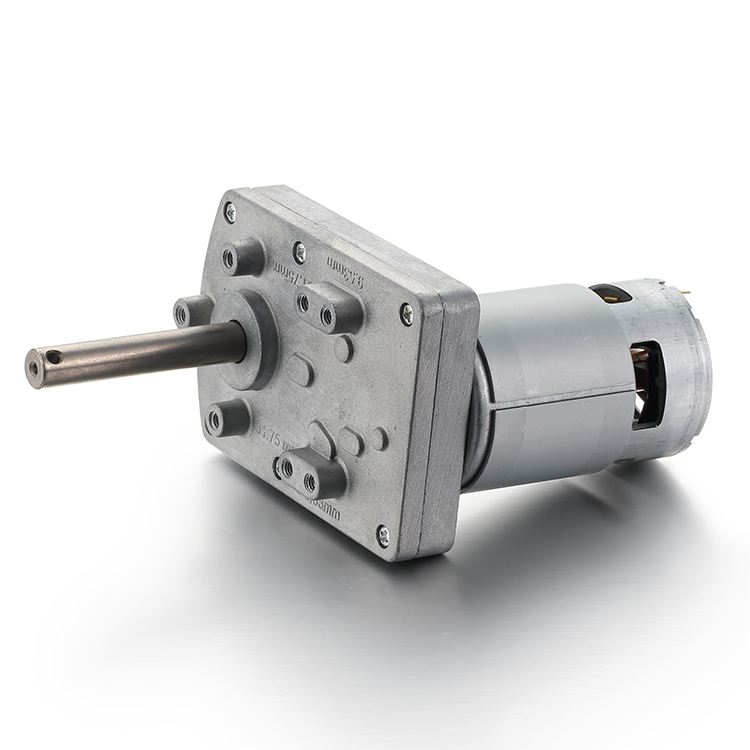

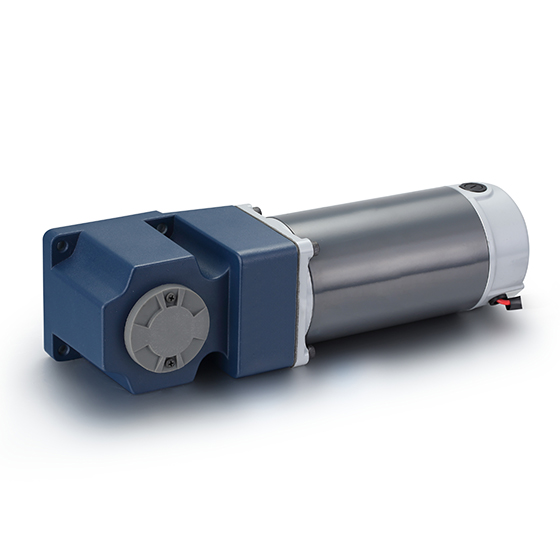

Description

| Environmental Conditons | —20℃~50℃ | Number of Phases | / |

| Rotation Direction | CW/CCW | Insulation Class | B-H |

| Noise | ≤65dB | Protection Class | IP40 |

| Work Condition | S1 |

Advantages

- 01Self-locking function: The worm gear motor has a self-locking function, which can prevent reverse movement, and is suitable for lifting and safety braking and other occasions that need to prevent reverse movement.

- 02Compact structure:The worm gear motor provides a large reduction ratio while being relatively small in size and compact in structure.

- 03Low vibration and noise: Due to the large gear contact surface, the vibration and noise of worm gear motors are low.

- 04Smooth transmission: The meshing mode of the worm gear ensures the stability of the transmission, which is suitable for occasions that require stable transmission.

Motor Technical Data

| Electrical Specifications | |||||||||

| Model | RATED LOAD | NO LOAD | STALL | ||||||

| Voltage | Power | Speed | Torque | Current | Speed | Current | Torque | Current | |

| V | W | rpm | N.m | A | rpm | A | N.m | A | |

| BG 5551230 | 12 | 3.3 | 2200 | 0.015 | 0.8 | 3000 | 0.14 | 0.06 | 3 |

| BG 5551245 | 12 | 7.2 | 3300 | 0.022 | 1.2 | 4500 | 0.22 | 0.088 | 4.8 |

| BG 5552460 | 24 | 13.5 | 4500 | 0.03 | 1 | 6000 | 0.18 | 0.12 | 4 |

| We can also customize products according to customer requirements. | |||||||||

| Spur Gear Motor Technical Data-BG | ||||||||

| Reduction ratio (1:xx) | 36 | 66 | 94 | 196 | 211 | 277 | 624 | 1166 |

| Rated speed (rpm) | 125 | 68 | 48 | 23 | 21 | 16 | 7 | 4 |

| Rated torque (N.m) | 0.7 | 0.7 | 1.6 | 2 | 2 | 2 | 5 | 5 |

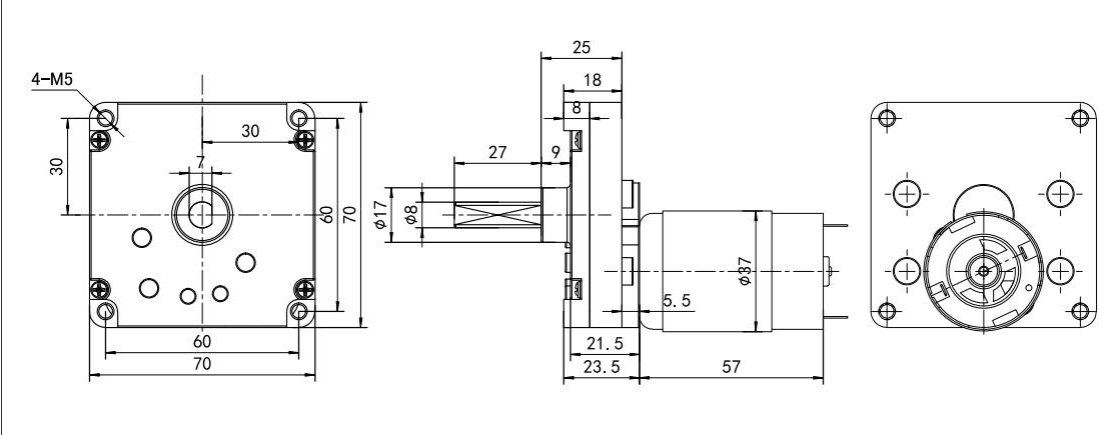

Mechanical Dimensions

Customizable solutions

Can provide custom voltage, electrical performance, circuit, etc.

And shaft, installation flange, lead wire, high-temperature class, drive, etc.

If you have any other needs, please contact our sales engineers

Parts

Applications

Motor Selection Details

01Scenarios and working conditions:

Determine what kind of application the geared motor will be used for, such as conveyor machinery, lifting equipment, conveyor belts, etc.Determine operating conditions, such as ambient temperature, humidity, and whether waterproof, dustproof, and other characteristics are required.

- 02Required output parameters:

Determine the required output speed and output torque.Determine the required reduction ratio, i.e. the ratio of the speed of the input shaft to the output shaft.

03

Space Constraints And Installation Requirements:Determine the size and shape of the installation space.Determine if there are special installation requirements, such as vertical installation, horizontal installation, etc.04Motor Performance And Efficiency Requirements:

Determine the requirements for motor efficiency, such as whether a high-efficiency motor is required to save energy.Determine the requirements for the stability of the motor operation and the noise level.

05Economic Considerations:

Consider the customer's budget constraints and recommend products that fit the budget and meet the needs.06Additional Features And Special Requirements:

If there are special functional requirements, such as self-locking function, emergency braking function, etc., you need to understand the specific needs of customers in detail07Finally:

By gathering and understanding these details, we can more precisely recommend the most suitable geared motor for our customers to meet their specific application needs and expected performance requirements.