Electric Motors: The Backbone of Modern Machinery

Electric motors power our world, converting electrical energy into mechanical energy to drive machines, vehicles, and industrial processes, revolutionizing countless industries globally.

Electromagnetism: The Core of Electric Motors

Electric motors rely on electromagnetism to create rotational force, where magnetic fields interact with current-carrying conductors to generate mechanical motion. This principle powers motorized equipment across industrial and domestic applications.

Dive deeper into the types, components, applications, and innovations in the electric motor industry to uncover its vast potential.

Electric motors come in various types, each designed for specific applications:

1. AC Motors (Alternating Current Motors):

Widely used in industrial manufacturing, these motors are robust and efficient, suitable for high-power applications. Subtypes include synchronous and induction motors.

2. DC Motors (Direct Current Motors):

Ideal for applications requiring precise control, like robotics. Subtypes include brushed and BLDC motors.

Compact and reliable, these motors are popular in automotive systems and small devices due to their low power requirements.

Includes stepper motors for precise movements and servo motors for applications needing tight control, such as CNC machines.

Electric motors rely on a combination of essential components to function effectively:

1.Rotor and Stator:

The rotor (moving part) and stator (stationary part) create motion via magnetic interactions.

2.Windings:

Conductive coils generate electromagnetic fields when current passes through.

3.Commutator or Electronics (for DC/BLDC Motors):

Controls current direction to ensure continuous rotation.

4.Bearings:

Support the rotor, enabling smooth and efficient rotation.

5.Housing and Cooling Systems:

Protect internal components and manage heat dissipation for longevity and efficiency.

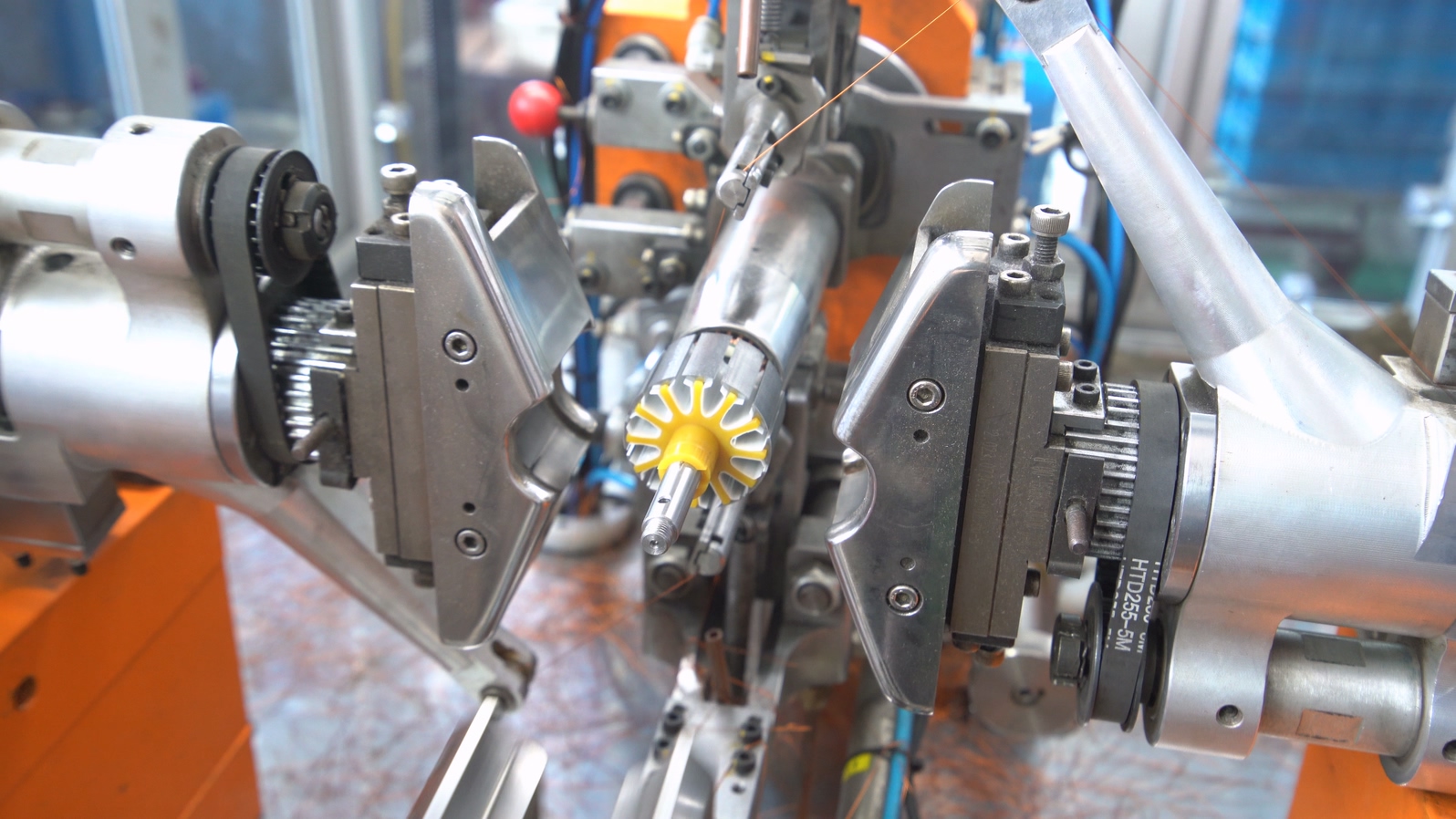

(The above is the BG Motor shaded pole motor voltage test)

The performance and reliability of electric motors depend on rigorous quality assurance processes:

1.Performance Testing:Measures torque, speed, and efficiency to ensure compliance with specifications.

2.Durability Testing:Simulates prolonged usage conditions to evaluate wear and tear.

3.Safety Testing:Ensures insulation and thermal resistance meet industry standards, reducing risks of overheating or failure.

4.Certifications:Products often meet international standards like ISO, CE, and NEMA for assured quality.

Electric motors are pivotal in numerous sectors:

1. Industrial Manufacturing:Powering conveyors, pumps, and machinery for production lines.

2. Transportation:Used in electric vehicles, trains, and aircraft.

3. Consumer Electronics:Found in household appliances like fans, blenders, and washing machines.

4. Renewable Energy:Driving wind turbines and solar-powered devices.

5. Healthcare:Supporting precision medical devices and mobility aids.

The electric motor industry is undergoing rapid evolution driven by technological advancements:

1.Energy Efficiency:Development of high-efficiency motors reduces energy consumption and carbon footprint.

2.Miniaturization:Compact motors like 12VDC motors for portable and space-constrained applications.

3.Smart Motors:Integration with IoT for predictive maintenance and optimized performance.

4.Sustainability:Use of recyclable materials and eco-friendly designs.

BG Motor leads the electric motor industry with innovative products and unmatched expertise:

1. Comprehensive Portfolio:Offers BLDC motors, AC motors, and 12V DC motors for diverse needs.

2. Customization:Tailors motor designs for specific industrial manufacturing and motorized equipment applications.

3. Quality Focus:Adheres to stringent testing protocols and international standards for reliability.

4. Global Reach:Serves clients worldwide, offering robust support and timely delivery.

Electric motors power modern innovation. From industrial manufacturing to consumer devices, BG Motor drives progress with cutting-edge solutions for every need.

BACK

BACK

Electric Motors: The Backbone of Modern Machinery Electric motors power our wor…

Since its establishment in 1994, Bogong has been deeply involved in the …

Precision and power are essential in modern machinery. High torque motors fulfil…

Torque in a motor refers to the rotational force generated to perform work. It’s…

Thanksgiving in the United States is a major holiday, celebrated on the fourth T…

Alternating current (AC) powers nearly every modern device. However, many people…