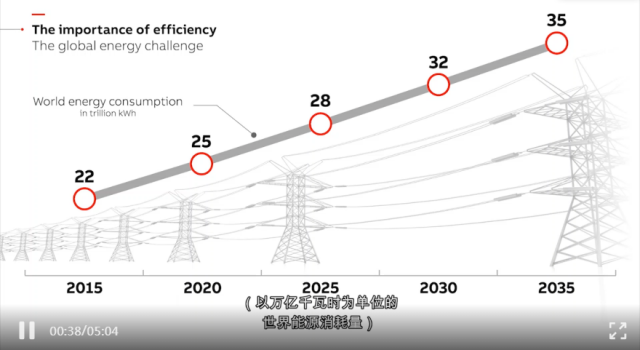

The world is facing severe energy challenges. The demand for electricity is growing faster than any other form of energy demand. The pressure to reduce energy consumption and carbon dioxide emissions are everywhere. Climate change is a common survival and development crisis faced by mankind. The whole world pays attention to carbon neutralization. In this issue, we will discuss the importance of motor efficiency.

World energy consumption: in trillion hours; The simplest way to address this challenge is to seize the opportunity to reduce energy consumption through more efficient use of energy.

Why concentrate on electric motors?

More than 42% of the electricity is consumed by industry, and two-thirds of the energy is used by motors. Improving efficiency by using more efficient motors will save a lot of energy and reduce carbon dioxide emissions, which prompted governments to launch MEPs (minimum energy efficiency standard), which stipulates the mandatory minimum efficiency standard for motors.

In order to save energy and protect the environment, high-efficiency motor is the current international development trend. The United States, Canada, and Europe have issued relevant laws and regulations one after another. According to the running time of motors, the CEMEP standard formulated in Europe divides the efficiency into three levels: Eff1 (highest), Eff2, and Eff3 (lowest), which will be implemented step by step from 2003 to 2006. The newly issued IEC 60034-30 standard divides the motor efficiency into IE1 (corresponding to eff2), IE2 (corresponding to eff1), IE3, and IE4 (maximum).

So what is motor efficiency?

Efficiency is only the ratio of output power to input power and is expressed in percentage. Let's look at a standard motor with an output of 75kW. 80.9kw power input is required to achieve this output. Using our formula, we can get an efficiency of 92.7%, which also means that the power loss reaches 5.9kw. Where do these losses come from and how to minimize these losses, So as to improve the efficiency of the motor?

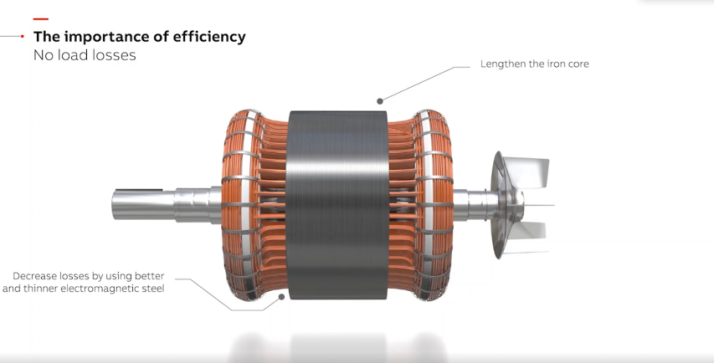

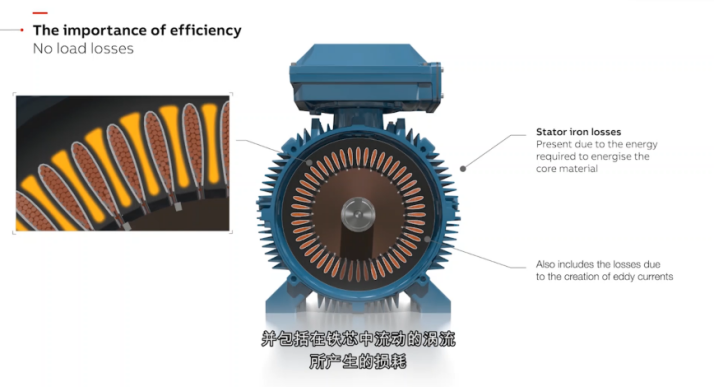

We will explain this in a simplified way. The no-load loss shown here is almost always constant regardless of the motor load. The stator iron loss is caused by the energy required to magnetize the iron core material and includes the eddy current flowing in the iron core. These losses can be reduced by using better and thinner electromagnetic steel and lengthening the iron core.

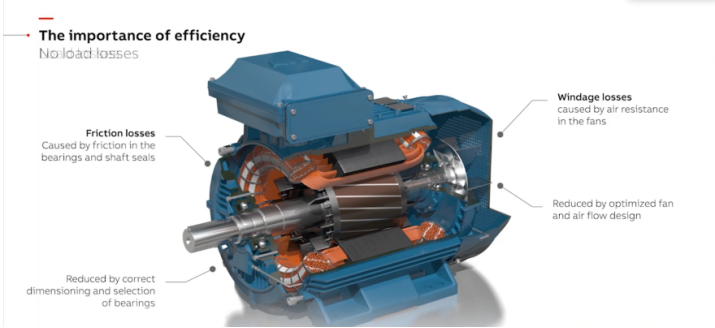

The friction loss is caused by the friction between the bearing and the shaft seal. It can be reduced by correctly dimensioning and selecting appropriate bearings. The wind resistance loss is caused by the air resistance of the fan. It can be reduced by optimizing the fan and airflow design. In addition to the no-load loss, we also have load loss, including three types: stator winding loss or I2R loss, It is caused by the resistance of the current flowing through the stator winding. They can be reduced by optimizing the stator slot design, that is, closely winding the winding to ensure a good slot filling rate, and optimizing the iron core to maximize the magnetic field strength.

Rotor loss: the rotor will also produce loss, I2R loss caused by rotor current, and iron loss caused by the interaction between magnetic flux and rotor core. They can reduce the loss by increasing the size of the guide strip and end ring to produce smaller resistance.

The additional load loss or stray load loss is caused by the mechanical defects in the leakage gap caused by the change of winding and the irregularity of air-gap flux density. They can be reduced by changing the geometry of the air gap slot and minimizing air gap deviation. Unfortunately, the loss is an inevitable part of motor operation, because it will directly affect efficiency.

BG motor a high-end motor manufacturer, will try its best to reduce them. We will use better quality materials, leading motor design, and manufacture them in high-precision automatic factories. Its loss can be kept to a minimum, which means that with the design of each generation of motors, the efficiency will be improved, which will help to solve some global energy challenges Carbon neutralization makes a contribution to reaching the standard and makes an effort for our common home climate.

In order to meet customers with different use scenarios and equipment, we have developed a high-efficiency brushless DC motor, DC servo motor, DC permanent magnet synchronous motor, DC brush motor, and single-phase series excitation motor. If you have any needs, BG motor can provide you with high-efficiency motor solutions.

BACK

BACK

Electric Motors: The Backbone of Modern Machinery Electric motors power our wor…

Since its establishment in 1994, Bogong has been deeply involved in the …

Precision and power are essential in modern machinery. High torque motors fulfil…

Torque in a motor refers to the rotational force generated to perform work. It’s…

Thanksgiving in the United States is a major holiday, celebrated on the fourth T…

Alternating current (AC) powers nearly every modern device. However, many people…