RV worm gear reducer is a new type of reducer, which has two types: single-stage and double-stage. The utility model has the advantages of compact structure, light volume, small size, and high efficiency. The "square box" shape structure is made of high-quality aluminum alloy die-casting, and the box shape is beautiful. At present, RV Reducer has been widely used in mechanical reducer devices of production process equipment in various industries, which is highly praised by the market. At present, modern industrial equipment is the best choice to realize mechanical reduction transmission control devices with high torque, high-speed ratio, low noise, and high stability.

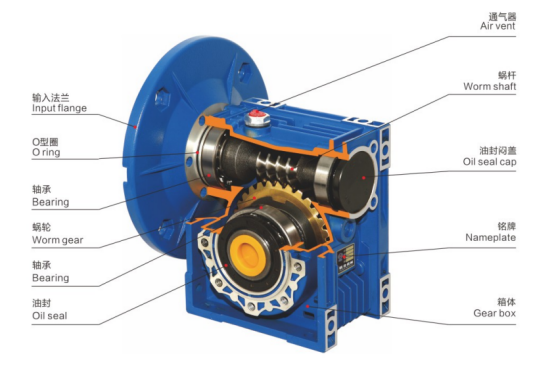

Composition of RV worm gearbox :

Type of RV Worm Gearbox :

Type: the input type of aluminum alloy reducer is divided into four types: hole input (NMRV), shaft input (NRV), shaft input with extension (NRV-VS), and flange input with extension (NMRV-VS).

The output forms include hole output, one-way shaft output (NRV-AS), two-way shaft output (NRV-AB), and flange output (NRV-F).

Input mode: motor direct connection, motor belt connection or input shaft, connection flange input.

Output mode: hollow shaft output or solid shaft output.

RV worm gear box has the following advantages:

1. Compact structure, light volume, small size, and high efficiency;

2. Good heat exchange performance and fast heat dissipation;

3. Simple installation, flexible and light, superior performance and easy maintenance;

4. Large rotating speed ratio, large torque, and high overload bearing capacity;

5. Stable operation, low noise, and long service life;

6. Strong practicability, high safety, and reliability;

Main materials of RV worm gearbox :

1. Shell: aluminum alloy (base: 025-090) cast iron (base: 110-150);

2. Worm: 20CrMnTi, carburized and quenched, tooth surface hardness 56-62hrc, maintain carburized layer thickness of 0.3-0.5mm after fine grinding;

3. Worm gear: wear-resistant tin bronze;

RV worm gearbox selection method:

Symbols and units of measurement

P: Power (kW)

P: Input power P: output power

P select motor power

η. D dynamic efficiency

η. D is the relationship between P2 and P1 calculated after the surface temperature of the worm gearbox drops and finally stabilizes after running for a long enough time.

η. s: Static efficiency.

η. S is the efficiency of the worm gearbox at the start-up stage, which is a very important consideration in the selection of an intermittent working system.

RV worm gearbox selection considerations:

Load condition

Use speed range or speed ratio (combined with bipolar, E-UDL, etc.)

Operating conditions and environment (temperature, humidity, corrosion)

Installation space

Example of RV worm gearbox selection:

The torque of the driven equipment is 150nm, the input speed is 1400R / min, the output speed is 70r / min, medium load, 8 hours of operation per day, 20 starts per hour, and the ambient temperature is 30 ℃. Motor requirements B3 installation orientation

(1) Speed ratio N1 = 20 / N2 = 1400

(2) Determine the working coefficient, medium load, select K2 curve, take the intersection of 20 frequencies, and find that f = 125 for 8 hours/day

(3) The temperature is 36 ℃, and the temperature coefficient is 11 Then f = 125 * 11 = 1.38

(4) Determine the selected torque M > m2fs = 150x143 = 214.5nm

(5) Check the performance parameter table and it meets three conditions. The speed ratio is 20m equal to or greater than 2145nmfs, which is equal to or greater than 1.38. The closest one is e-rv90-20-b3-2.2-4

The input power of the driven equipment is 1.5KW, the input speed is 900r / min, the output speed is 60R / min, heavy impact load, 16 hours of operation per day, 100 starts per hour, and the ambient temperature is 20 ℃.

(1) Determine the speed ratio L = N1 / N2 = 900 / 60 = 15

(2) Determine the working coefficient and heavy load, select the K3 curve, find the intersection of 16 hours and 100 times and find that f = 1.9

(3) If the temperature is 20 ℃ and the temperature coefficient is 10, the correction is f = 19x1 = 1.9

(4) Determine the motor PP1 · FS = 15x1 9=2.85kw

(5) Check the performance parameter table and it meets three conditions. If = 15F is equal to or greater than 19p1n is equal to or greater than 285kw, the closest one is e-rv110-15-132s6

Calculation method of the speed ratio of RV series worm gearbox :

The speed ratio of RC series reducer refers to the ratio between the rated speed NN (R / min) of the motor and the speed NL of the output shaft of the reducer when the mechanical reducer is adopted, which is called speed ratio 1 (also known as transmission)

Ratio) I = NN / NL.

Calculation method of reduction ratio:

The rated power of RV Reducer Motor is p (kW) and the speed is N1 (R / min). The total transmission ratio and transmission efficiency of the reducer are U. Then: output shortening = 9550 * p * u * I / N1 (N.m)

1. Definition and calculation method: reduction ratio = input speed ÷ output speed

2. General calculation method: reduction ratio of RV Reducer = applied torque ÷ 9550 ÷ motor power input revolutions of motor power ÷ service factor

3. Calculation method of gear train: reduction ratio three, number of driven gear teeth ÷ number of driving gear teeth (in case of multi-stage gear reduction, the number of driven gear teeth of the combined pair of gear sets ÷ number of driving gear teeth, then multiply the results.

4. Calculation method of reduction ratio of RV Reducer belt, chain, and friction wheel: reduction ratio = driven wheel diameter ÷ driving wheel diameter.

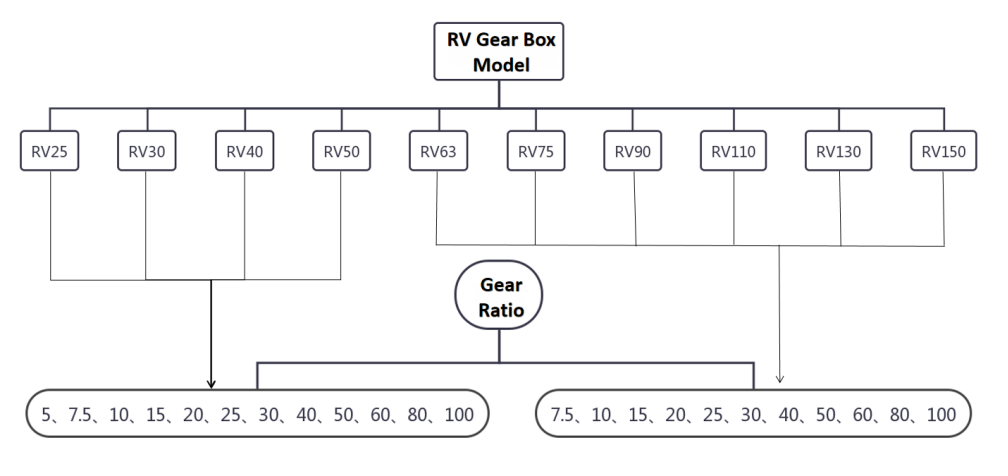

Model and speed ratio of RV worm gearbox :

NMRV25、NMRV30、NMRV40、NMRV50、NMRV63、NMRV75 NMRV90 NMRV110 NMRV130 NMRV150

Installation methods: foot installation, hollow shaft installation, flange installation, torque arm installation, and small flange installation

Center distance: 25 30 40 50 63 75 90 110 130 150

Speed gear ratio: 1:5 1:7.5 1:10 1:15 1:20 1:25 1:30 1:40 1:50 1:60 1:80 1:100

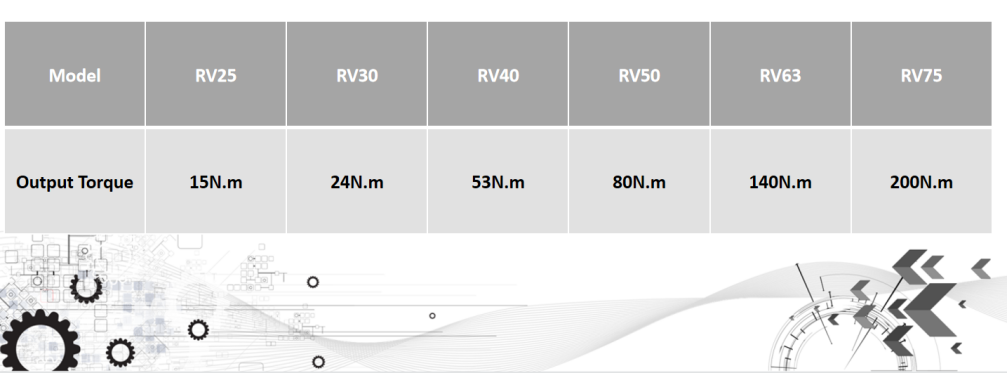

Output torque range of RV worm gear reducer:

If you still don't understand how to choose a more suitable RV gearbox model after reading the above information, you can consult the professional sales engineer of BG motor, and we will select and recommend a more suitable motor and RV worm gearbox for you.

BACK

BACK

Electric Motors: The Backbone of Modern Machinery Electric motors power our wor…

Since its establishment in 1994, Bogong has been deeply involved in the …

Precision and power are essential in modern machinery. High torque motors fulfil…

Torque in a motor refers to the rotational force generated to perform work. It’s…

Thanksgiving in the United States is a major holiday, celebrated on the fourth T…

Alternating current (AC) powers nearly every modern device. However, many people…