Inefficient fan motors can lead to high energy consumption, noise, and frequent maintenance. These problems increase operational costs and reduce product lifespan. The solution lies in adopting Brushless DC (BLDC) motor technology for fans.

BLDC fans use advanced technology that eliminates the need for mechanical brushes, resulting in quieter operation, increased energy efficiency, and longer product lifespans. These motors are ideal for both residential and commercial applications, offering significant energy savings and reducing maintenance costs.

To understand these advantages in detail, let’s explore how BLDC motors revolutionize fan technology.

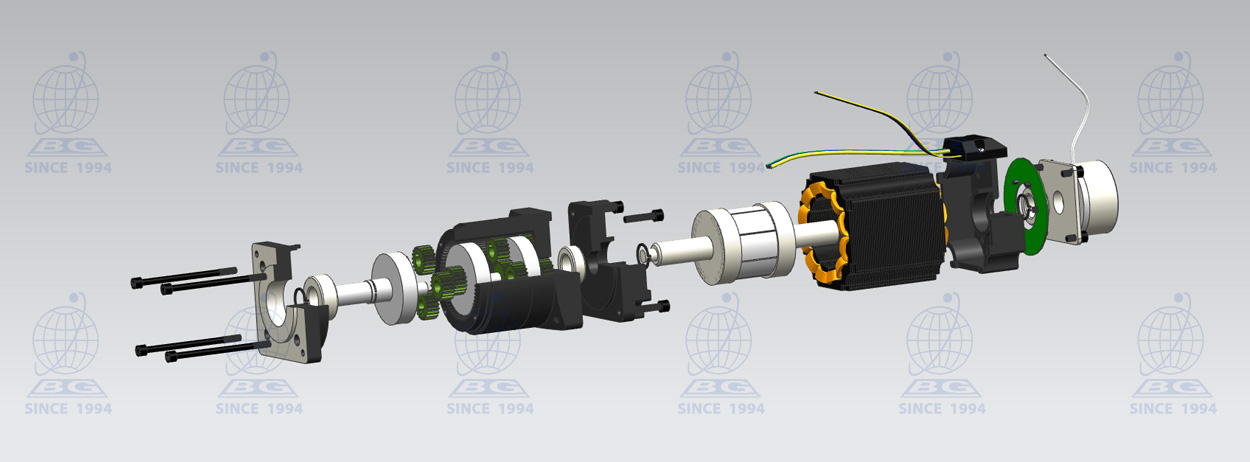

A BLDC fan operates using a Brushless DC motor, which is powered by electronic commutation rather than mechanical brushes. This technology eliminates the wear and tear typically associated with traditional motors. Instead of relying on brushes to transfer power, a BLDC fan uses a permanent magnet rotor and an electronically controlled stator. This setup reduces friction and heat, which significantly improves the motor’s lifespan and performance. As a result, BLDC fans are more energy-efficient, quieter, and require less maintenance compared to traditional AC motor fans.

High efficiency and energy saving

The brushless motor fan avoids the energy loss caused by brush friction through electronic commutation, and the motor runs with high efficiency. At the same time, precise control circuitry ensures efficient operation under different workloads. Especially in environments that require a large number of fans, such as data centers and servers, the use of brushless fans can significantly reduce overall energy consumption.

Low noise design

Brushless motors have no mechanical contact between the brushes and the commutator, so there is virtually no brush friction noise during operation. In addition, brushless motor fans using high-precision control algorithms can further reduce windshear noise through smooth commutation and low-vibration blade design, making them ideal for noise-sensitive applications such as offices, bedrooms, medical equipment, etc.

Adjustable speed

The brushless motor fan is electronically controlled for more flexible speed control and can even be automatically adjusted according to temperature or environmental conditions. This adjustable speed not only improves the energy efficiency of the equipment, but also reduces unnecessary excessive heat dissipation and fan wear.

Long life and maintenance-free

Compared to brushed fans, brushless motor fans have no brush wear problems, so they have a longer service life and are maintenance-free. In environments that require long-term stable operation, such as servers, communication equipment, and industrial equipment, this maintenance-free feature can greatly reduce the frequency of repairs and replacements.

Higher security

The electronic controller of the brushless motor fan can monitor the operating status of the motor in real time to prevent overload, overheating and other problems. This improves the overall safety of the fan, especially when working at high temperatures or in complex environments, ensuring that the equipment can operate reliably.

The key difference between a normal ceiling fan and a BLDC fan lies in their motor technology. Normal ceiling fans use AC motors, which are less efficient and noisier due to the friction caused by brushes. In contrast, BLDC ceiling fans use brushless motors, which are powered by electronic circuits, resulting in quieter operation and significant energy savings. Additionally, BLDC fans can adjust speeds more smoothly and provide better airflow. BLDC ceiling fans also have a longer lifespan and lower maintenance costs, making them a more sustainable choice for modern homes and businesses.

BG Motor is a leading fans brushless motor supplier, focusing on advanced BLDC technology. The key feature of BG brushless motors is their electronic commutation system, which replaces traditional brushes with a solid-state controller. This controller regulates the motor’s speed, torque, and efficiency through precise signals. BG motors also feature permanent magnet rotors, which enhance power output while reducing energy consumption. Another critical technological point is the BLDC motor controller, which enables variable speed settings and reduces power losses. This technology allows BG Motor fans to operate efficiently across a range of applications, from residential to industrial uses.

BG Motor produces a variety of brushless motor types tailored for different fan applications:

Axial fans: These are ideal for high airflow environments such as industrial ventilation or cooling systems. The BLDC motors in axial fans offer high-speed operation while minimizing power consumption.

Centrifugal fans: For environments requiring high-pressure airflow, centrifugal fans with BLDC motors are the perfect choice. These fans deliver efficient air movement in confined spaces, such as HVAC systems and ducting.

Exhaust fans: Compact and energy-efficient, BLDC motors in exhaust fans provide effective air extraction with minimal noise, making them ideal for homes, offices, and bathrooms.

Each type of fan benefits from BG’s brushless motor technology, offering optimized performance and energy efficiency.

As a top BLDC fan manufacturer in China, BG Motor offers customized motor solutions for your specific fan requirements. Whether you need a BLDC fan motor for residential ceiling fans, industrial cooling systems, or ventilation fans, BG Motor has the right solution. Our BLDC motors are designed to meet your energy-saving goals while providing superior performance. In addition to offering motors, we provide comprehensive support, including motor selection, design consultation, and after-sales service. With BG Motor, you get reliable, efficient, and high-quality brushless motor solutions tailored to your needs.

BLDC fans provide key advantages in terms of efficiency, longevity, and performance, making them the best choice for modern fan applications.

Power Range:5W-20KW

Voltage Range:DC6V-310V,AC110V,220V,50/60Hz

Rated Speed Range:1500-100,000RPM

Size Range(diameter):28MM-258MM

Shaft:Based on the drawing you offered,we can process the shaft into corresponding diameter,length and shape.

Mounting hole:We can located the mounting hole with your requirement within reasonable range.

Protection Class:Based on your needs,up to IP68

Install method:Adjust motor into horizontal or vertical arrangement fit for your product.

Insulation Class:With your requirement,we can used varnished wire with different thermal resistance to reach class B-F.

The parts can be paired with brushless motor:Gear box,brake,encoder and driver.

BACK

BACK

Thanksgiving in the United States is a major holiday, celebrated on the fourth T…

On October 19, 2024, the first offline exhibition of the 136th Canton Fair came …

The October sun shines on BG's production workshop, reflecting a vibrant pic…

BG Motor is committed to the customized professional production of motors, since…

On October 15, 2024, the 136th Canton Fair was officially held in Guangzhou, Chi…

Summary of Canton Fair 1. History of the Canton Fair2. Canton Fair time3. Canton…