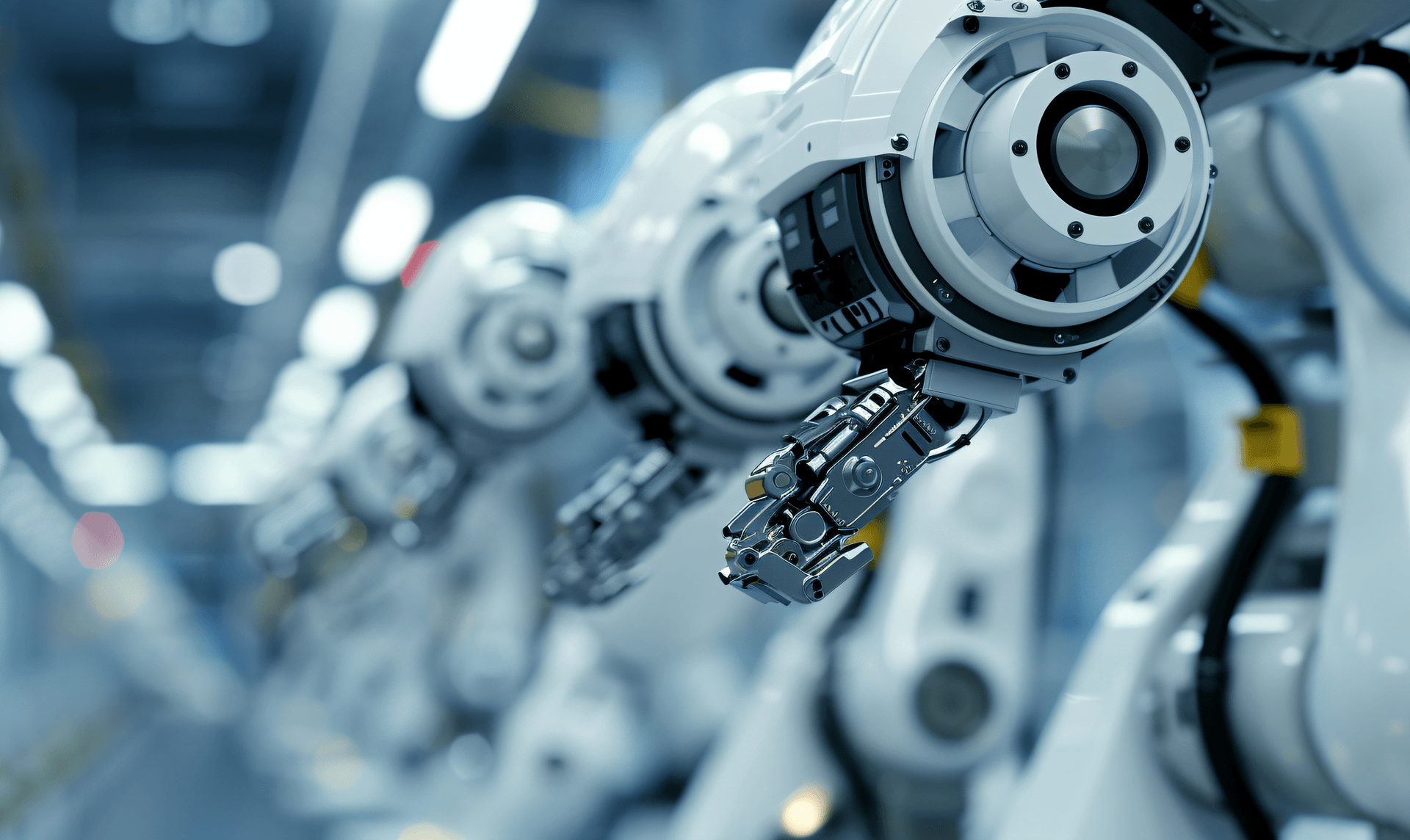

Robotic systems today struggle with inefficiency due to outdated motor technology. This can lead to costly delays and performance issues. BG Motor provides innovative motor solutions to enhance robotic performance.

Motors are the heart of robotic systems, powering every movement and action. Without reliable motors, robots cannot perform their tasks efficiently, making motor selection crucial for optimizing functionality and performance in automation.

The performance of a robot is directly influenced by the motors it uses. Choosing the right motor is critical for ensuring smooth operations.

Robot motors power the movements, speed, and precision of robotic systems. They convert electrical energy into mechanical motion, allowing robots to perform tasks like lifting, rotating, and positioning. For instance, in industrial settings, motors control robotic arms, enabling the robot to move materials, weld components, or assemble parts with high accuracy. In service robotics, motors allow robots to navigate environments or perform repetitive tasks without fatigue.

Several types of motors are commonly used in robotics, depending on the application:

1. Brushless DC Motor (BLDC Motor)

Brushless DC motors are very suitable for robot manufacturing due to their high efficiency, low noise, long life and low maintenance. They can provide stable power output for robots, especially in collaborative robots and service robots. BLDC motors can achieve low noise, precise control and high efficiency, adapt to complex working environments, and are usually used in robotic arms.

2. Brushless DC Planetary Gear Motor

This motor combines a brushless DC motor with a planetary gearbox to provide high torque and high-precision motion control. It is very suitable for industrial robots that require precise positioning and robot arms in automated production lines. While maintaining a small size, the motor can provide high torque output and adapt to installation requirements in small spaces.

3.DC Brushed Motor

BG Motor's DC brushed motor has the advantages of simple structure and easy control. It is suitable for some medium and low load and cost-sensitive robot application scenarios. In addition, DC brushed motors have high starting torque and a wide range of speed regulation capabilities. Although the life and efficiency of brushed motors are relatively low, they still have certain advantages in some economical robot projects.

4. DC Brushed Planetary Gear Motor

This type of motor combines the characteristics of a brushed motor and a planetary gearbox, and can provide higher torque output in a limited volume. It is very suitable for robots with limited space and high load capacity, such as AGV carts or industrial automation equipment.

5. Robot Motors

BG Motor provides special motors for robot application scenarios, with high precision, high torque, low noise and other characteristics, especially suitable for industrial robots, collaborative robots and intelligent robot arms that require precise control. Our robot motors also have strong customization capabilities, which can be tailored according to customer needs, and provide specially designed shafts, mounting holes and drive solutions to ensure a perfect fit with customer equipment.

6. Stepper Motors

These allow for precise control over motion and positioning, perfect for tasks requiring accurate repeatability, such as 3D printing and CNC machines.

7. Servo Motors

These motors provide feedback control, making them ideal for applications where exact movements and positions are required.

The best motor for a robot depends on its intended application. For industrial robots, brushless DC motors are often the top choice due to their high efficiency, long lifespan, and low maintenance. These motors deliver smooth, continuous power, making them ideal for heavy-duty applications, such as in robotic arms or automated machinery. Stepper motors, on the other hand, are better for tasks requiring precision but lower torque, such as in hobbyist robots or small-scale automation.

When choosing a motor, key factors to consider include:

Power and Torque: Power and torque are the maximum requirements for robot motor matching, and different use scenarios have different needs

Efficiency: Motors with high efficiency reduce energy consumption, which is vital for robots running continuously.

Size and Weight: The motor must fit within the robot's design constraints.

Noise and Vibration: Low-noise motors are ideal for environments where minimal sound is essential, like medical or household robots.

At BG Motor, we tailor motor solutions to fit your robot’s specific needs, ensuring optimal performance and reliability.

BG Motor’s products are widely used in robotic systems across various industries:

Manufacturing Robots: Our DC brushed and brushless motors power robotic arms for assembly lines, ensuring speed and precision.

Service Robots: In the cleaning and healthcare sectors, BG motors drive robots to perform repetitive tasks like cleaning floors or assisting patients.

AGV (Automated Guided Vehicles): We provide motors for AGVs used in warehouses, improving the automation and efficiency of material handling.

Drone:We provide high-precision, long-life, low-noise drone motors

BG Motor offers customized motor solutions to meet the specific demands of your robotic systems. Whether you need high-torque motors for robotic arms or low-vibration motors for medical robots, our engineering team works closely with you to develop the ideal motor solution. We also offer integrated systems including gearboxes, encoders, and brakes, ensuring seamless performance.

Power Range:1W-1000W

Voltage Range:DC3V-220V

Rated Speed Range:1500-6000RPM

Size Range(diameter):28MM-130MM

Shaft:Based on the drawing you offered,we can process the shaft into corresponding diameter,length and shape.

Mounting hole:We can located the mounting hole with your requirement within reasonable range.

Protection Class:Based on your needs,up to IP65

Install method:Adjust motor into horizontal or vertical arrangement fit for your product.

The parts can be paired with brushless motor:Gear box,brake,and encoder

Customized Solution -DC Brushless Motor

Power Range:5W-20KW

Voltage Range:DC6V-310V,AC110V,220V,50/60Hz

Rated Speed Range:1500-100,000RPM

Size Range(diameter):28MM-258MM

Shaft:Based on the drawing you offered,we can process the shaft into corresponding diameter,length and shape.

Mounting hole:We can located the mounting hole with your requirement within reasonable range.

Protection Class:Based on your needs,up to IP68

Install method:Adjust motor into horizontal or vertical arrangement fit for your product.

Insulation Class:With your requirement,we can used varnished wire with different thermal resistance to reach class B-F.

The parts can be paired with brushless motor:Gear box,brake,encoder and driver.

BACK

BACK

Electric Motors: The Backbone of Modern Machinery Electric motors power our wor…

Since its establishment in 1994, Bogong has been deeply involved in the …

Precision and power are essential in modern machinery. High torque motors fulfil…

Torque in a motor refers to the rotational force generated to perform work. It’s…

Thanksgiving in the United States is a major holiday, celebrated on the fourth T…

Alternating current (AC) powers nearly every modern device. However, many people…