Precision and efficiency are crucial in modern healthcare, driving demand for advanced medical motors.

With the rapid evolution of medical technology, high-performance medical motors have become essential in developing compact, portable, and efficient healthcare devices, enabling improved patient care and operational reliability in diverse medical environments.

Medical motors are the driving force behind medical devices, providing them with the necessary power and precision. Read this article to understand the mystery behind medical motors.

Typical Applications of Electric Motors in Medical Equipment

Electric motors are fundamental in a range of medical devices, from diagnostic to therapeutic and surgical applications. Typical applications include:

Surgical Robots: Medical robots, such as surgical arms, require BLDC (Brushless DC) motors for precise control and smooth movement. The motors ensure accuracy during delicate surgical procedures.

Patient Care Devices: Motors in patient beds, wheelchairs, and lifting systems offer patient mobility and comfort through reliable gear motors and DC motors.

Diagnostic Imaging: Motors enable the scanning mechanics in MRI, CT, and ultrasound machines. The precision of BLDC motors ensures smooth imaging, reducing noise and vibration.

Laboratory Equipment: High-speed micro motors are used in centrifuges and mixers to process samples, increasing efficiency in laboratory operations.

Ventilators and Respirators: Small, efficient medical motors regulate airflow, crucial for life-support systems that must function flawlessly.

Characteristics of Medical Motors

Motors used in medical applications require specific characteristics to ensure patient safety, device reliability, and efficiency:

High Precision and Responsiveness: Medical devices demand precise positioning and smooth operation, achievable with brushless DC (BLDC) motors that offer exceptional control and low noise.

Low Noise and Vibration: Quiet motors improve the comfort of patients and reduce environmental distractions in healthcare settings, especially in diagnostic equipment.

High Efficiency: Medical motors must optimize power use, as they are often used in battery-powered portable devices. Efficient motors also reduce the device’s heat, protecting sensitive medical environments.

Long Lifespan: Reliability is critical; medical motors with minimal wear, such as BLDC motors, can operate for extended periods, lowering maintenance costs.

Compact Design: Space-saving designs ensure motors fit within portable or handheld devices, such as micro motors used in minimally invasive surgical tools.

Different motor types meet diverse medical requirements. Key types include:

Brushless DC (BLDC) motors: Ideal for precision and efficient applications such as robotic surgery and diagnostic equipment. They operate quietly and have a long service life due to reduced mechanical friction.

DC Brushed Motor: with high efficiency and wide speed regulation function, it is widely used in syringe pumps, input pumps, and dental medical equipment.

Gear Motors: Used in patient care equipment and lifting systems, gear motors provide high torque in a compact design, making them suitable for heavy-duty tasks in tight spaces.

Planetary Gear Motors: Due to their compact design, high torque output, and high efficiency, they are ideal for use in medical devices that require durability and stability. Such as surgical robots, medical care equipment, etc.

Right angle gear motor: Because of its unique structural design, the power can be transmitted through an angle of 90 degrees, which is widely used in the adjustment system of the operating bed, the angle control of the surgical light, the angle and position adjustment of dental equipment, etc.

Micro motor: a small multi-functional motor for handheld and minimally invasive equipment. Micromotors are critical in dental tools, surgical drills, and lab equipment that require precision in confined areas.

Customized solutions: Some applications require specific customization of motor size, speed, or power output. BG Motor focuses on providing tailor-made motor solutions to meet these unique medical needs, providing optimized solutions for medical device manufacturers.

BG Motor delivers reliable, high-quality motors designed to meet strict medical standards. Elements of BG Motor’s solutions include:

Customization Flexibility: BG Motor works closely with clients to design motors tailored to specific medical applications, optimizing performance and meeting device specifications.

Precision Engineering: Motors are developed using advanced technologies such as electromagnetic simulation (ANSYS, MotorCAD) to ensure high performance and accuracy.

Strict Quality Control: Each motor undergoes rigorous testing and certification to ensure it meets quality and safety standards, crucial for sensitive medical applications.

Eco-Friendly Materials: BG Motor uses only certified, eco-friendly materials, ensuring safety for healthcare environments while supporting sustainable practices.

If you want to get a more detailed understanding, please contact our engineers technology@china-bgmotor.com in detail.

BG Motor’s solutions are designed for optimal performance in medical settings, featuring:

High Efficiency: Optimized designs reduce energy consumption, supporting battery life in portable medical devices.

Low Noise: BG’s brushless DC motors and gear motors are engineered for minimal noise, improving patient experience and creating a calmer medical environment.

Long Life and Durability: With quality materials and precise construction, BG Motor products have a long operational lifespan, reducing replacement and maintenance needs.

Professional Team and Manufacturing Capacity: BG’s experienced engineers and extensive production facilities ensure quick turnarounds on large orders and customizations.

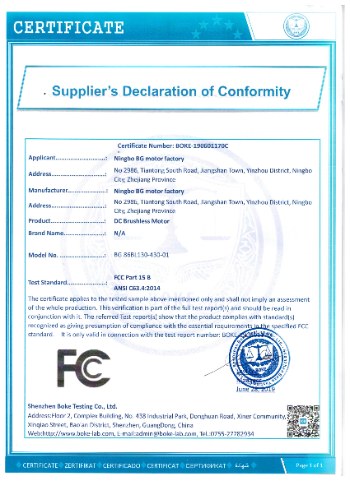

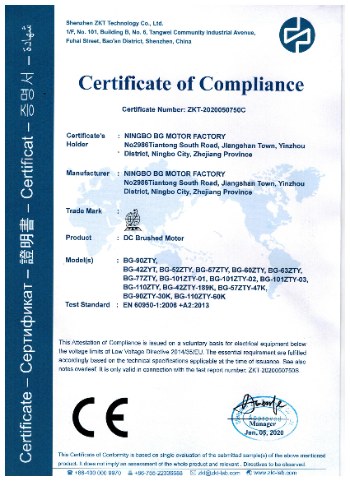

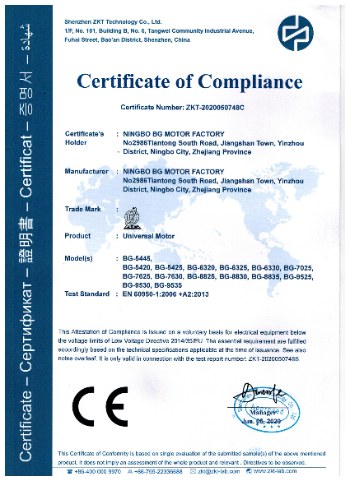

Comprehensive Data Certification: Motors come with data certifications, ensuring reliability and compliance with international standards, including CE, ROHS, and FCC.

On-Time Delivery: BG Motor’s reliable supply chain and manufacturing capabilities enable prompt delivery to meet critical project timelines.

So, if you have any needs, please contact our engineers, we will make a professional customized solution for you, perfect to meet your needs.

BG Motor is committed to becoming the most trusted motor manufacturer in the world.

BACK

BACK

Electric Motors: The Backbone of Modern Machinery Electric motors power our wor…

Since its establishment in 1994, Bogong has been deeply involved in the …

Precision and power are essential in modern machinery. High torque motors fulfil…

Torque in a motor refers to the rotational force generated to perform work. It’s…

Thanksgiving in the United States is a major holiday, celebrated on the fourth T…

Alternating current (AC) powers nearly every modern device. However, many people…