Motion control system is a branch of automation system, mainly used in the field of robotics and CNC machine tools. One of the challenges motion control engineers face is how to properly select the motor. Motors that are too small will not be able to handle the load and are not advisable. If the motor is oversized, the motor acquisition cost and operating cost will be too expensive. "How to choose the right motor to avoid oversizing?" has become a common concern among engineers.

Several factors affect motor size:

1. Inertia

One of the main challenges in motion control is overcoming inertia. Inertia is the tendency of an object to resist changes in acceleration. Overcoming inertia is a constant struggle for engineers, especially on assembly machines where motion cycles are short but high speeds are required. The motor needs to provide enough force in a linear system, or enough torque in a rotating system, to vary the acceleration of the load in a controlled manner.

The first step in properly sizing a motor is to calculate the load inertia. For example, the moment of inertia (J) of a rotating mass can be determined by:

J=mr²

This describes the moment of inertia of a point mass (m) at a specific distance (r) from the axis of rotation.

Load inertia is reflected back to the motor shaft from the load and the components in between. This value should include any other mechanical elements the motor is responsible for moving. This means that additional moving parts such as screws, pulleys, belts or couplings will demand higher performance from the motion control system.

For complex systems, finding an appropriate analytical expression depends on the weight, not the mass of the parts, since gravity causes acceleration. The motor sizing process requires total system inertia, including load inertia and motor inertia. The tendency among many engineers is to only calculate the actual load and gearbox as inertia, ignoring the weight and inertia of belts, pulleys, and other mechanical components.

The ratio of load inertia to motor inertia indicates how effectively the motor can control the load. When the inertia ratio is high, it indicates that the system may be having difficulty controlling the load. A lower inertia ratio clearly indicates the opposite. The motor will have an easier time and control the load more efficiently. However, a low inertia ratio can mean that the motor is oversized for the system, costs more, and is larger than necessary.

2. Performance Requirements of the Motor

(1) Speed and Torque

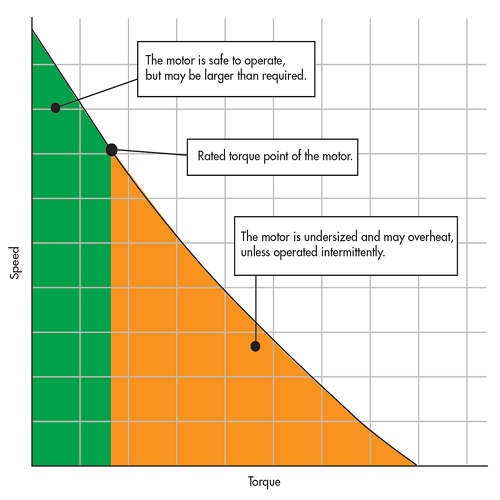

The speed-torque curve shows the rated torque point of the motor. The high end of the curve is where the motor can run safely, but the motor may be oversized (green area). At the low end of the curve, the size of the motor may be too small (orange area). Once the maximum torque of the motor is exceeded, the motor will stall, and all the current will be added to the coil, and there will be a short-term heating problem. If used for a long time, the motor is easy to burn out.

(2) Voltage and Power

The voltage and power of the motor are also important factors that limit the selection of the motor size. Generally speaking, under the same conditions, the larger the power supply voltage of the motor, the smaller the size of the motor; under the same conditions, the larger the power of the motor, the larger the size of the motor. If the motor size is limited by space, generally we increase the motor power by stacking magnet laminations while maintaining the same frame size. This would make the motor longer, but not increase the width.

In addition to these main influencing factors, the efficiency of the gearbox, the type of motor (such as a stepper motor, which does not require the cooperation of a gearbox, can be used in low-speed applications, greatly reducing the size of the motor.), the working environment of the motor (such as an explosion-proof motor, Motors used on plateaus, motors used on ocean ships, etc. will have different requirements for the internal structure design of the motor and the motor material, which will affect the size of the motor.), is also an important factor affecting the size of the motor.

In general, the size of the motor is affected by many factors. In order to provide you with the most suitable and economical motor solution, Ningbo Bogong Motor has equipped professional technicians. Your consultation is welcome!

BACK

BACK

In February 2025, BG Motor ushered in the traditional Lantern Festival celebrati…

The new year has begun, and BG Motor is officially back to work! After a refresh…

Dear Customers, Partners and Employees,On the occasion of the Spring Festival, B…

BG Motor, Ningbo, China, January 9, 2025 – As the festivities of Christmas and N…

At this juncture of saying goodbye to the old and welcoming the new, all BG Moto…

Originally commemorated the birth of Jesus, Christmas has become a powerful cult…