Client: Mr.Faber

Country: Germany

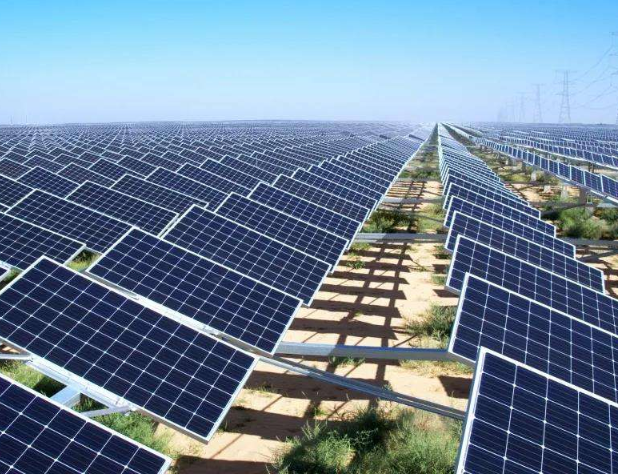

Industry: Photovoltaic solar panel

Cooperation time: 2015

The first oil crisis in the 1970s prompted developed countries to increase policy support and capital investment in renewable energy, including solar energy. After entering the 21st century, Europe and the United States, and other advanced countries began to incorporate photovoltaic grid-connected and off-grid power generation systems into the development direction. At the same time, under the severe energy substitution situation and the pressure of the human ecological environment, and driven by the gradually improved laws, regulations, and policies of various countries, the global photovoltaic industry presents a rapid development trend.

In 2015, a large photovoltaic solar energy listed company from Europe found us through Google. We are one of the Chinese suppliers they are looking for. They completely introduced their project to us and the development trend of this industry in the future. Our company has always been interested in the photovoltaic solar panel industry, but it is difficult for us to imagine that this product will use motors.

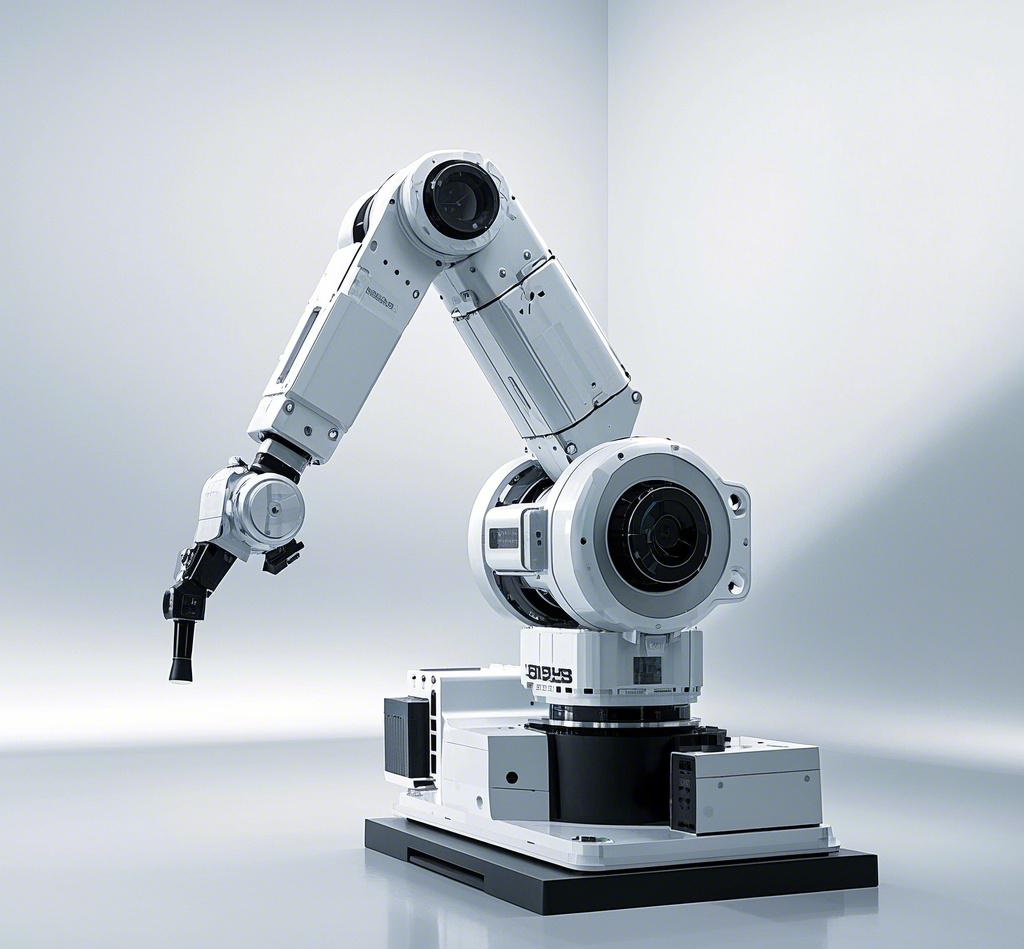

Why are motors used? Solar panels are all put into open deserts, grasslands, or mountains. However, due to the different illumination times and orientations of the sun, they need to absorb all the best sunlight. They need to install an Omni-directional light sensor or an Omni-directional sensor composed of multiple sensors to compare the light intensity in all directions. The solar panel can follow the strongest direction, The main function of the motor is to control the direction of rotating the solar panel.

The working environment of the motor: - 35 ℃ ~ 50 ℃ (due to desert areas, the ambient temperature in the use area is very high, and then the solar panels are exposed to the sun. Sometimes all solar panels have a temperature of 70 ° C or even do not work. After working, sometimes the working temperature of the motor exceeds 100 ° C.)

Insulation grade of motor: grade F (all raw materials shall use insulation materials above 150 ℃);

The lubricating oil temperature used for planetary reducer must be: - 35 ℃ ~ 100 ℃;

The gear of planetary reducer must be hobbed;

Breakdown resistance test must be conducted for 24V, which must be 800V

Drive and motor: preferably integrated, with built-in driver

The motor must be fully sealed with a protection grade of IP65;

The customer's data requirements for the motor are very routine, mainly because the motor needs to be in a working environment of - 35 ℃ ~ 50 ℃, so we must consider the motor material and appearance size. Due to the large quantity, we should help the customer save the cost as much as possible.

Because the environment is always outdoor and the environment will be harsh, our motor insulation grade adopts grade H, which is higher than grade F required by customers.

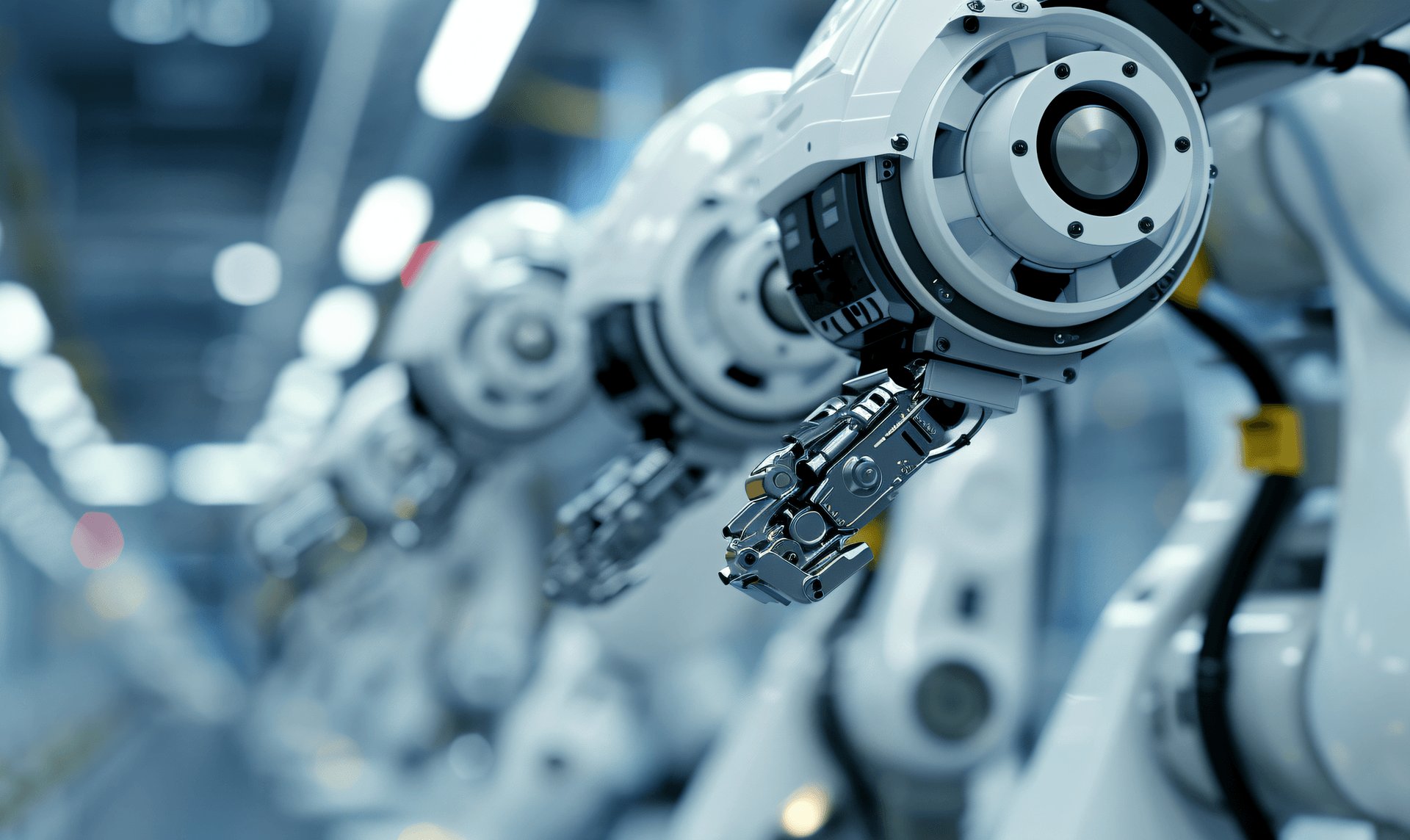

After discussion, our team first recommended the brushless DC planetary reduction motor to the customer, which is characterized by small volume, large torque, easy control, and sensitive response;

Because it is used in desert areas, the temperature of the solar panel is 70 ℃ under normal circumstances. The cable sleeve of the outgoing line must also withstand sufficient high temperature, and all details must be considered in place;

The lubricating oil and bearing materials of the planetary reducer need special customization to reach - 35 ℃ ~ 100 ℃;

Due to the high power of the motor, the driver cannot be built into the motor. We suggest that customers directly customize the external small driver, which can better save costs.

The breakdown resistance test of the motor fully meets the requirements of 800V;

After 5 samples, the motor fully met the customer's use requirements in 2016 and officially entered mass procurement!

It is a privilege to work with reliable and high-quality partners such as yourself. I feel honored. Thank you very much for all the help and great support in past years. let me say I can't imagine working with some other company. you are the best.

-Mr.Faber(Chief technical engineer)

BACK

BACK

BG Motor insisting on producing the best quality motors for our customers.