Client: John, American

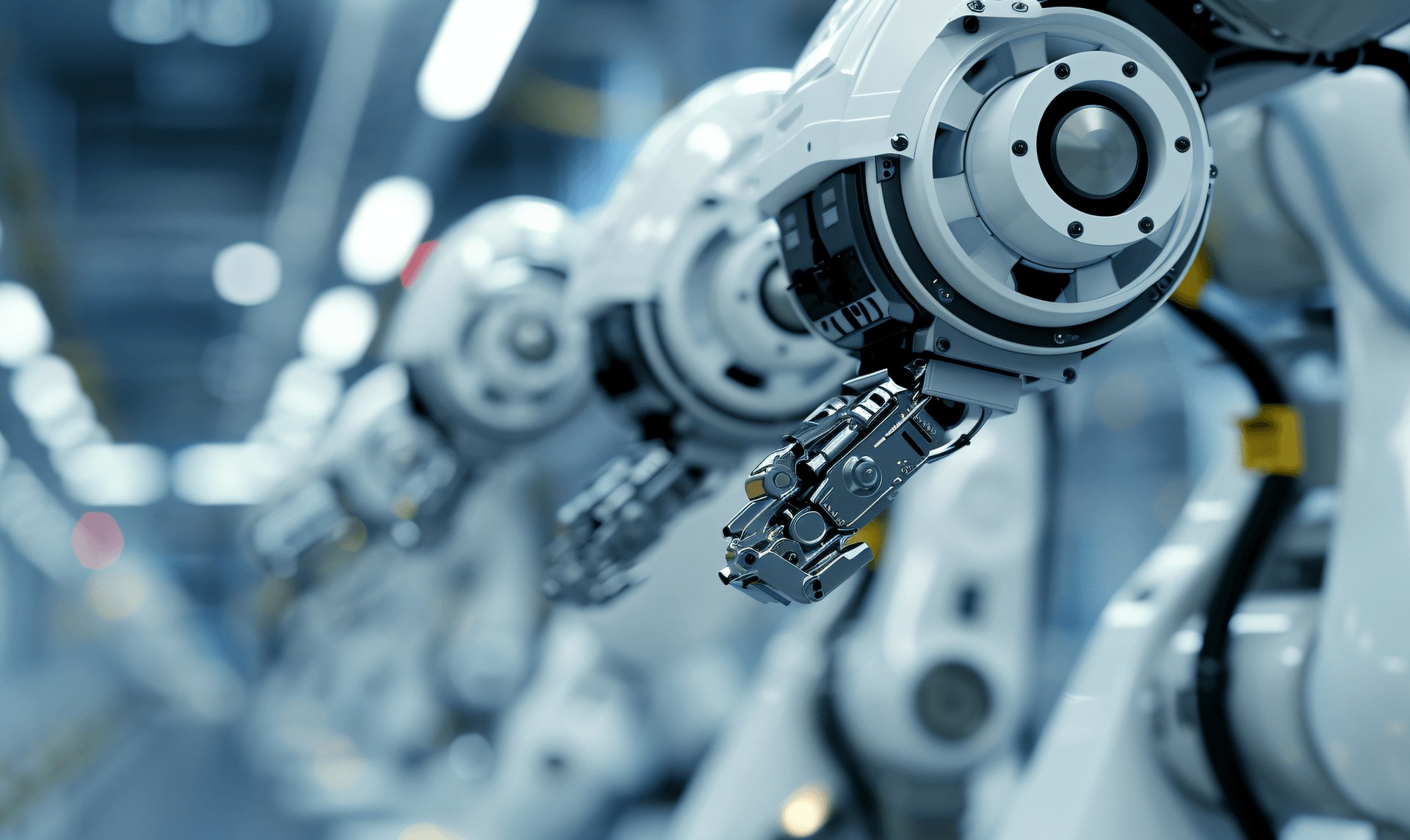

Industry: Robot R&D

Cooperation time: May 2022

In modern manufacturing, automation technology is driving the improvement of production efficiency. A United States manufacturer of emerging industrial transportation robot arms is committed to developing a high-performance robot arm that can meet the needs of diverse applications. However, they faced a number of challenges during the design process: precise motion control, low-noise operation, and a long-term stable service life. This set of requirements makes the choice of motor crucial for them.

The manufacturer's main challenge was to choose a motor that would fit its robot arm.

First of all, the working environment of the arm requires the motor to operate in a low-noise state to ensure that the application in hospitals and other quiet environments will not cause interference;

Secondly, it needs to have a high torque output to adapt to complex grasping tasks;

Finally, the motor must have a long service life to reduce maintenance costs and increase user satisfaction.

After in-depth market research and technical evaluation, the manufacturer finally chose the 24V, 250W, 100N.m high-precision motor developed by our company. This motor has been professionally customized and has the following core benefits:

Low noise:When running, the motor can be kept at a very low noise level, which meets the standards of hospital and home environment.

Precise control:The control accuracy is strong, and the data can be customized.

High torque:The torque output of 100N.m enables the robot arm to easily grasp and move various items, improving work efficiency.

Wide adjustable speed range:Combined with the gearbox, the motor can achieve a variety of low speed settings from 50rpm to 200rpm, which is perfectly adapted to different application scenarios.

Durable:The motor is designed with high-quality materials to ensure that it can maintain excellent performance over a long period of time.

Better thermal management:Brushless motors have lower heat generation, helping to improve overall system stability and reliability.

In cooperation with the manufacturer, we provided comprehensive technical support to help them smoothly integrate the motor into the robot arm and optimize it for the specific application.

We are well aware that excellent products are inseparable from excellent after-sales service. Therefore, we provide customers with a full range of technical support and services, including regular maintenance, troubleshooting, and remote technical guidance. Our professional team always maintains close communication with our customers to ensure that the motor is always in top condition in long-term operation.

With our high-precision, long-life motors, the manufacturer has successfully increased the market competitiveness of its robot arms and won wide recognition from customers. This successful case not only demonstrates our technical strength, but also lays a solid foundation for more cooperation in the future. We look forward to working with more industry partners to jointly promote the development of automation technology."

BACK

BACK

BG Motor insisting on producing the best quality motors for our customers.