Client: Mr.Kevin Jackson

Country: UK

Industry: Stairlift Machine

Cooperation time: 2015

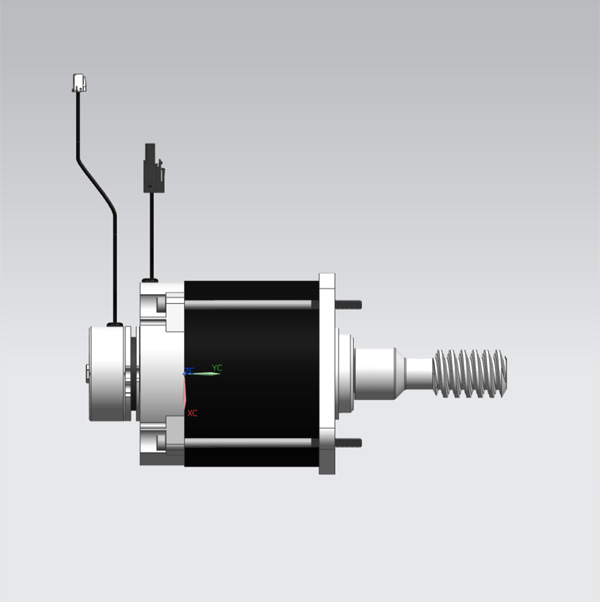

In 2015,the customer was looking for a 90mm, 24V, 20Nm, 30rpm worm gear motor to use in their new Project.Their company specializes in different types of home lifts,This project is specifically for the elderly who have difficulty getting up and down the stairs. It was a very meaningful design project.

The emergency brake prevents the stair lift from traveling too fast due to gravity, so there is a high demand for the quality of the electromagnetic brake.

The motor needs to be installed with an oversized gearbox, without the assistance of accessories such as front cover, which can be very challenging for installation.

The length of the motor must not exceed 100mm.

The noise of the motor must be less than 60dB, as the product is not allowed to have a lot of noise, and must ensure that the motor is quiet during operation.

The output shaft diameter needs to be increased by 20mm, because the output shaft needs to bear the secondary drive class.

We need to ensure the quality of the worm gear precisely.

In response to the clear demands of the customer, our founder and engineer team first solved problem of motor’s length.Normally as the power reached 300W, the diameter of the motor is usually 110mm, but we need to solve the case of the diameter of 100mm.While the parameter must satisfy customer’s needs. Our engineers optimized the internal structure of the motor and changed the diameter of the original hollow bearing to solve the output shaft can reach 20mm.We produced in-house samples to simulate the usage scenario as the customer.To ensure with the requested size and performance, how to quickly one-piece installation, to control the lowest cost. Our engineers installed a simulated scenario lab by themselves, repeatedly verified the test pattern, and finally succeeded; the customer later shipped the whole large gearbox directly to our company, and we helped them to complete the installation in one go and export directly to the UK.

We have helped our customers develop 5 more motor products in a row, which we signed a confidentiality agreement to provide exclusively, and have been working together until now!

Their company makes me impressed with motor products made in China.Both their salesmen to engineers have very high professional knowledge, meticulous to each component.Our products require strong stability, so we are very concerned about the supplier's professionalism, technical ability, delivery ability, etc..They did a great job!

-Mr.Kevin Jackson

BACK

BACK

BG Motor insisting on producing the best quality motors for our customers.