Customer: Mr. Thomas, USA

Industry: Laser printer manufacturer

Cooperation period: 2018 to present

Market demand analysis

In today's modern printing field, laser printers have become the standard for high-quality and

efficient document production. At the heart of these devices is a key component: the DC brush

motor. Known for its versatility, reliability and cost-effectiveness, these motors play a vital role

in driving a variety of printing machines, ensuring precise and smooth operation.

Customer pain points

Mr. Thomas is a leading laser printer manufacturer in the United States. His previous DC brush motors faced multiple challenges:

Inconsistent print quality: Fluctuations in motor speed and torque lead to inconsistent toner deposition, resulting in varying print quality.

Noise pollution: Excessive motor noise disrupts the office environment and causes discomfort to users.

Short motor life: Frequent wear and tear can cause premature motor failure, increasing maintenance costs and downtime.

High energy consumption: Inefficient motors lead to increased electricity bills and environmental issues.

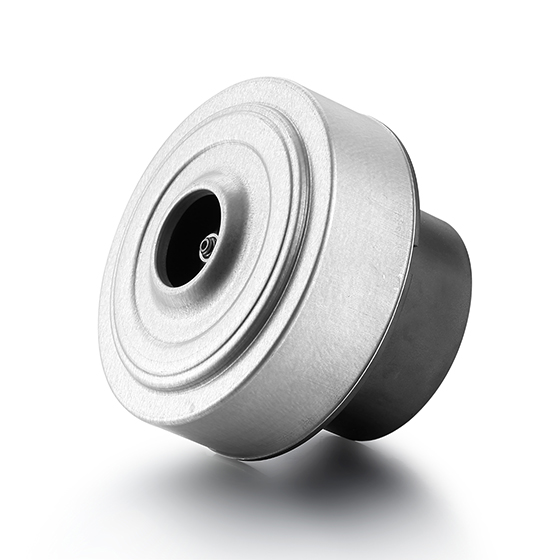

BG Motors has 30 years of experience in motor production and is well-known for its expertise

in DC motors. It provided Mr. Thomas with the following solutions: High-precision DC brush

motors with a conventional voltage of 24V; maximum power of 250W; brakes and encoders

can be added as needed

Precise speed control: BGDC63ZYT138 can achieve precise control through pulse width modulation

(PWM) technology to ensure motor speed and torque regulation, consistent toner deposition and

excellent print quality.

Quiet operation: Optimized motor design and noise reduction technology reduce noise levels to ≤65 dB,

Durable structure: From the manufacturing materials of the motor to the production process and

quality inspection of the finished motor, we ensure the excellent stability and reliability of BG Motor,

which can maintain stable performance in an operating environment of -20℃~50℃. High-quality

materials and solid structure extend the life of the motor, reduce maintenance costs, and optimize

the customer experience.

DC brush motors are relatively easy to control using basic electronic devices, simplifying their integration

into laser printer designs. This simple control scheme reduces complexity and improves manufacturing

efficiency. At the same time, it reduces the cost of production.

Laser printers run continuously, requiring motors that can withstand long hours of operation without compromising performance. Known for their ruggedness

and long life, brushed DC motors are an ideal choice.

Benefits:

BG Motors doesn’t just produce motors to customer needs; we go beyond standard solutions to achieve the best results based on our customers’ needs,

ensuring seamless integration and optimal performance.

BG Motors’ brushed DC motor solution has transformed Mr. Thomas’ laser printer:

Excellent print quality: Precise motor control produces crisp, clear, high-quality prints.

Low-noise environment: Low-noise motors result in a more comfortable working environment, which can improve office productivity.

Reduced maintenance costs: Extended motor life minimizes downtime and maintenance expenses.

Reduced manufacturing costs: Its simple design and manufacturing process means lower production costs, making it an affordable choice for manufacturers.

Customer satisfaction

Mr. Thomas is very satisfied with the performance and benefits of BG Motors brushed DC motors. He said:

"BG Motors' motor solutions have transformed our laser printers in many ways. The motors have significantly improved print quality, reduced noise levels,

extended motor life, and reduced energy consumption. We are very impressed with BG Motors' expertise, quality, and commitment to customer satisfaction."

Contact BG Motors today to learn how our brushed DC motors can power precision printing and improve your laser printer performance!

BACK

BACK

BG Motor insisting on producing the best quality motors for our customers.