Client: Aruba

Industry: Automotive manufacturers

Cooperation time: September 2023

As consumers' requirements for car comfort continue to increase, electric adjustment seats have become standard in modern cars. Electric seats need to have flexible adjustment functions, such as forward and backward movement, backrest angle adjustment, seat cushion height adjustment, etc., which requires the motor to have high precision, high torque and stable operating performance. An internationally renowned automobile manufacturer plans to upgrade its electric seat system to improve user experience and has found a partner that can provide high-performance customized reduction motors - BG Motor.

1. Space constraints:Automotive seating systems require small and compact motors that require small size and compact structures, but must provide high torque output to drive the seat adjustment mechanism.

2. Low noise requirements:The seat adjustment process needs to be as quiet as possible to ensure that the passenger experience is not disturbed by the noise of the motor.

3. Long life and high reliability:As an important interior part of the vehicle, the motor of the electric seat needs to be able to maintain long-term stable operation under frequent adjustment.

4. Performance to adapt to different environments:The complex environment in the car, including extreme conditions such as high temperatures, low temperatures, and humidity, requires electric motors with excellent weather resistance and protection ratings.

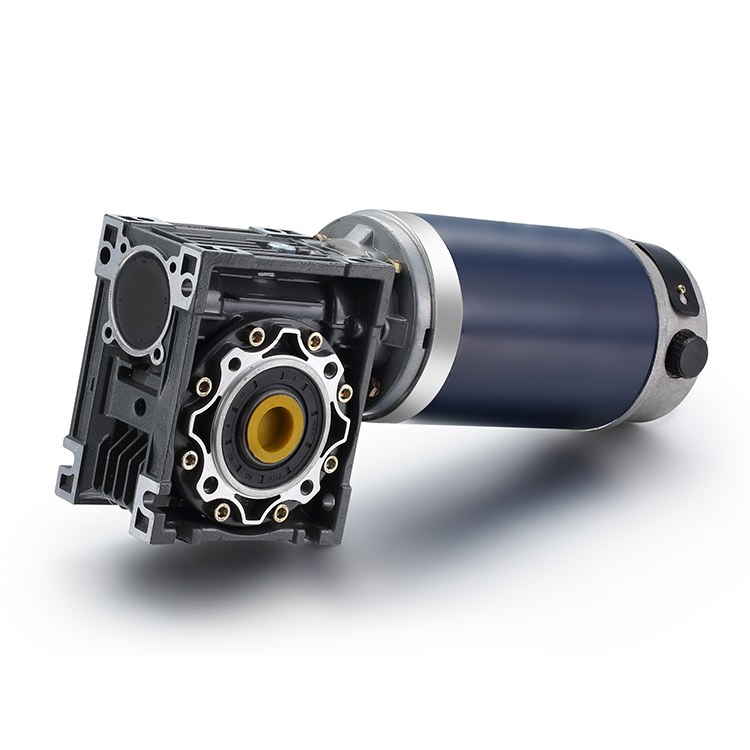

BG Motor designed a customized geared motor with a suitable reduction ratio and a small size according to the seat structure diagram provided by the customer.

1、Power range: In order to meet the adjustment needs of different directions of the seat, the motor power is designed from 50W to 150W.

2、Deceleration mechanism: Adopt high-efficiency planetary gear structure, and the output torque is greater than 15Nm, which ensures smooth seat adjustment.

3、Size optimization: The outer diameter of the motor is controlled within 50mm, which perfectly adapts to the space requirements of the seat system.

Using high-precision gear processing technology and noise-reducing materials, the motor runs with a noise of less than 35dB, which meets the silent standard of the automotive industry.

By optimizing the motor winding and material selection, it has an operating life of more than 20,000 hours; At the same time, high-temperature resistant enameled wire and anti-corrosion coating are used to ensure that the motor works normally in high temperature and humid environments.

For the special environment in the car, the motor design with IP65 protection level is provided to effectively prevent the intrusion of dust and moisture.

Through the close cooperation between BG Motor and the customer, the customized geared motor was successfully applied to the new electric seat, successfully solving the problems of space constraints, noise reduction, and reliability. The new chair has been well received by consumers for its smooth adjustment, quiet operation and long service life, helping customers further enhance their brand competitiveness.

BG Motor is committed to providing high-performance motor solutions for the automotive industry to help customers create better product experiences.

BACK

BACK

BG Motor insisting on producing the best quality motors for our customers.