Client: Chanrad

Industry: Vacuum cleaner manufacturer

Cooperation time: May 2022

A commercial cleaning equipment company plans to launch a high-performance wet and dry vacuum cleaner suitable for industrial workshops, hotels, shopping malls and other scenarios. The vacuum cleaner needs to have both strong suction, low noise, long life and excellent protection to accommodate high-strength cleaning tasks. Customers hope that the motor can provide stable suction while having good dust-proof and waterproofing capabilities to cope with humid and dust-intensive working environments.

1. The suction force of an ordinary vacuum cleaner motor is difficult to reach 16kPa, which affects the cleaning efficiency, especially the poor absorption effect of liquid stains and heavier particles.

2. Because the equipment works in a humid and dust-intensive environment for a long time, ordinary motors are prone to moisture damage or performance deterioration due to dust accumulation, which affects the service life.

3. Excessive noise in motor operation will affect the user experience, especially in hotels, office areas and other environments. Low noise is one of the important needs.

4. Excessive motor power consumption will shorten the battery life of the equipment. Customers hope to optimize energy consumption and improve the motor working efficiency.

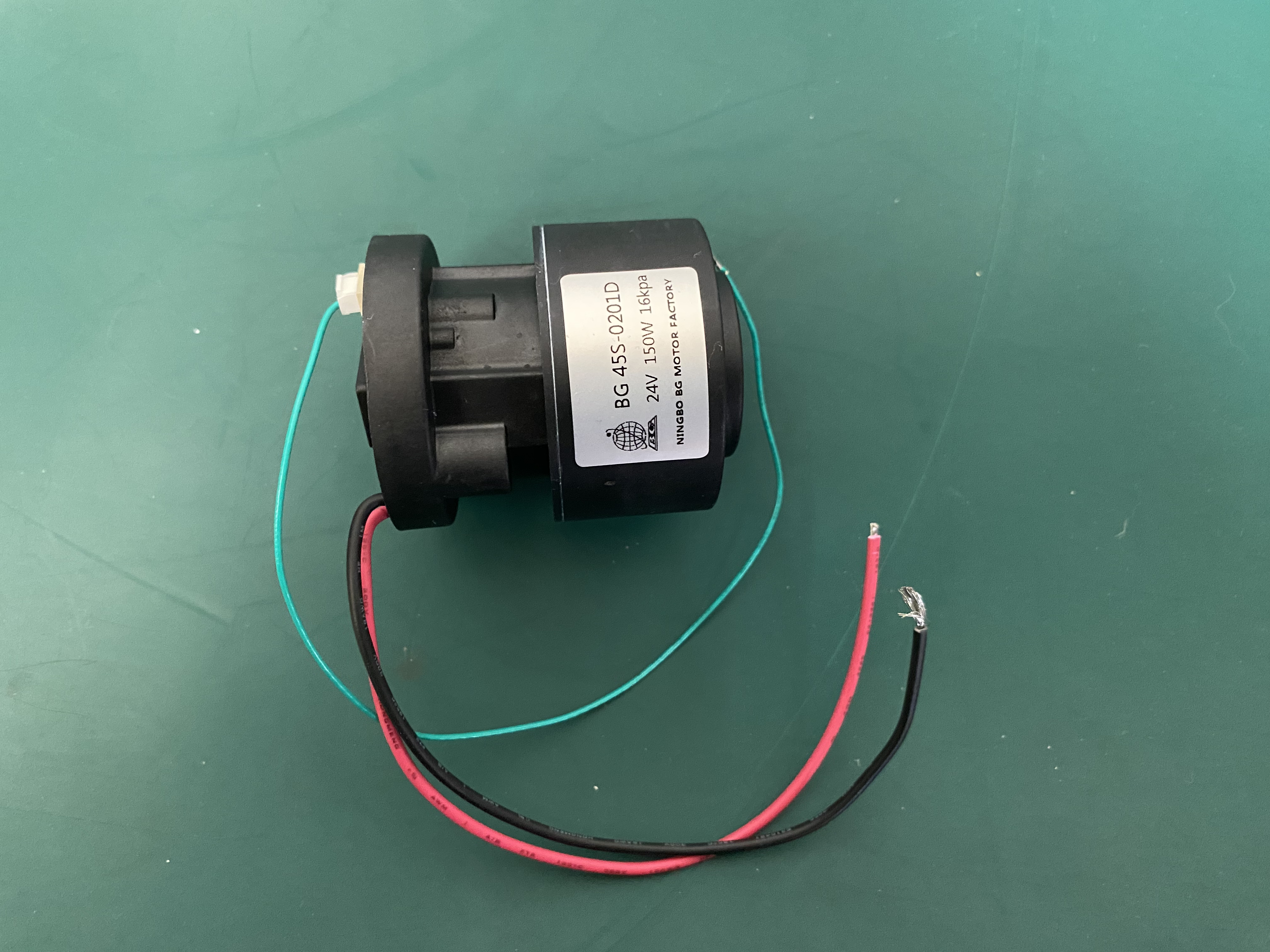

To meet customer needs, BG Motor provides a 24V 150W 16kPa high-performance vacuum cleaner motor and has carried out multiple optimized designs.

First of all, in terms of suction, the motor adopts high-efficiency impeller and optimized air duct design to increase the air flow rate so that it can achieve a high negative pressure of 16kPa at 150W power, ensuring that the vacuum cleaner can efficiently clean solid and liquid impurities.

Secondly, in terms of protection performance, the motor adopts IPX5-level protection design, optimizes the sealing structure and improves waterproof and dustproof capabilities. Special sealing materials can effectively block the invasion of water vapor and dust, reduce motor damage caused by environmental factors, and extend service life.

In terms of noise reduction and vibration reduction, the motor has been dynamically balanced and adopts a low-noise design to control the operating noise within 58dB, reducing vibration, improving overall comfort, and meeting the needs of commercial environments.

In order to improve energy efficiency, the motor optimizes the magnetic circuit and winding parameters, improves energy conversion efficiency, so that it can reduce.

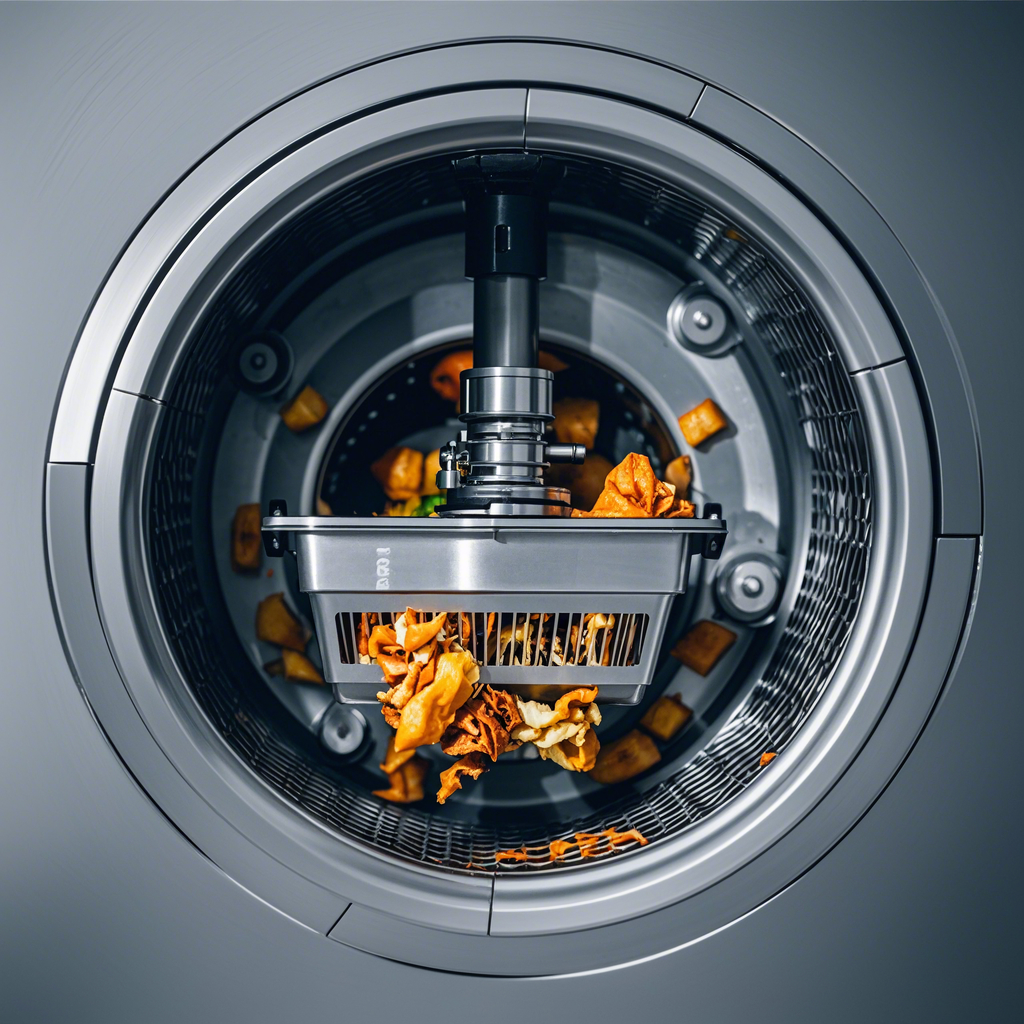

The motor performed well after being applied to the customer's wet and dry vacuum cleaner. The vacuum cleaner can maintain stable suction under different working conditions, and the motor has good protection performance. Even if it is used for a long time in a humid environment, there is no water inlet or dust blockage, which greatly reduces maintenance costs. Low noise design makes the equipment more suitable for commercial places, while high-efficiency energy consumption management also enhances the market competitiveness of the products. The customer expressed satisfaction with the performance of the motor and planned to continue to adopt the BG Motor solution in subsequent products.

BG Motor is always committed to providing customers with high-performance customized motor solutions. If you have similar needs, please contact us to jointly create efficient and stable vacuum cleaners.

BACK

BACK

BG Motor insisting on producing the best quality motors for our customers.