Client: William Brown

Industry: Home Manufacturer

Cooperation time: July 2024

A well-known European manufacturer of household accessibility equipment plans to upgrade its Stair Lift to accommodate more complex stair environments, including straight and curved staircases. The customer wanted to use a drive motor with high torque, low noise, stable operation, durability and reliability, and at the same time required the equipment to have safety protection functions in the event of sudden power failure and ensure the stability of long-term operation.

As chaired stair lifts are primarily used by the elderly and people with reduced mobility, safety and comfort become key considerations. As a result, the customer was looking for a motor solution that could provide high torque, quiet operation, safety and stability.

1. High requirements for smooth operation

During the operation of traditional motors, they are prone to jitter or uneven acceleration, which affects user comfort. The customer was looking for a motor that would start precisely and accelerate smoothly without discomfort during seat operation.

2. Adaptability requirements for different staircase structures

The customer's products include straight and curved seat lifts, which require motors that are adaptable enough to match different track structures and maintain a stable output in turns.

3. Strong torque and compact structure coexist

The motor of the seat lift needs to provide enough power in a confined space to drive the seat up and down the track smoothly and with loads of up to 120-150kg.

4. Quiet operation to improve user experience

Since most of the equipment is installed in residential buildings, the customer has extremely high noise requirements, and wants the noise of the motor to be less than 50dB when it is running, so as to ensure a quiet and comfortable home environment.

5. Reliability of long-term use

Chair stair lifts need to run frequently every day, and the motor must have a long life, high durability, and be able to withstand long hours of work and maintain stable performance.

BG Motor provided the customer with a combination of PMDC Motor and Geared Motor optimized for seated stair lifts, which perfectly solved the customer's needs.

Motor model: BG-DC57-24V/150W

Rated torque: 12Nm (higher torque can be customized upon request).

Rated voltage: 24VDC, with built-in battery, ensures operation even when power is off.

Noise control: Optimized winding design and high-precision machining, operating noise less than 50dB.

Energy-efficient: 15% more energy efficient and less power loss.

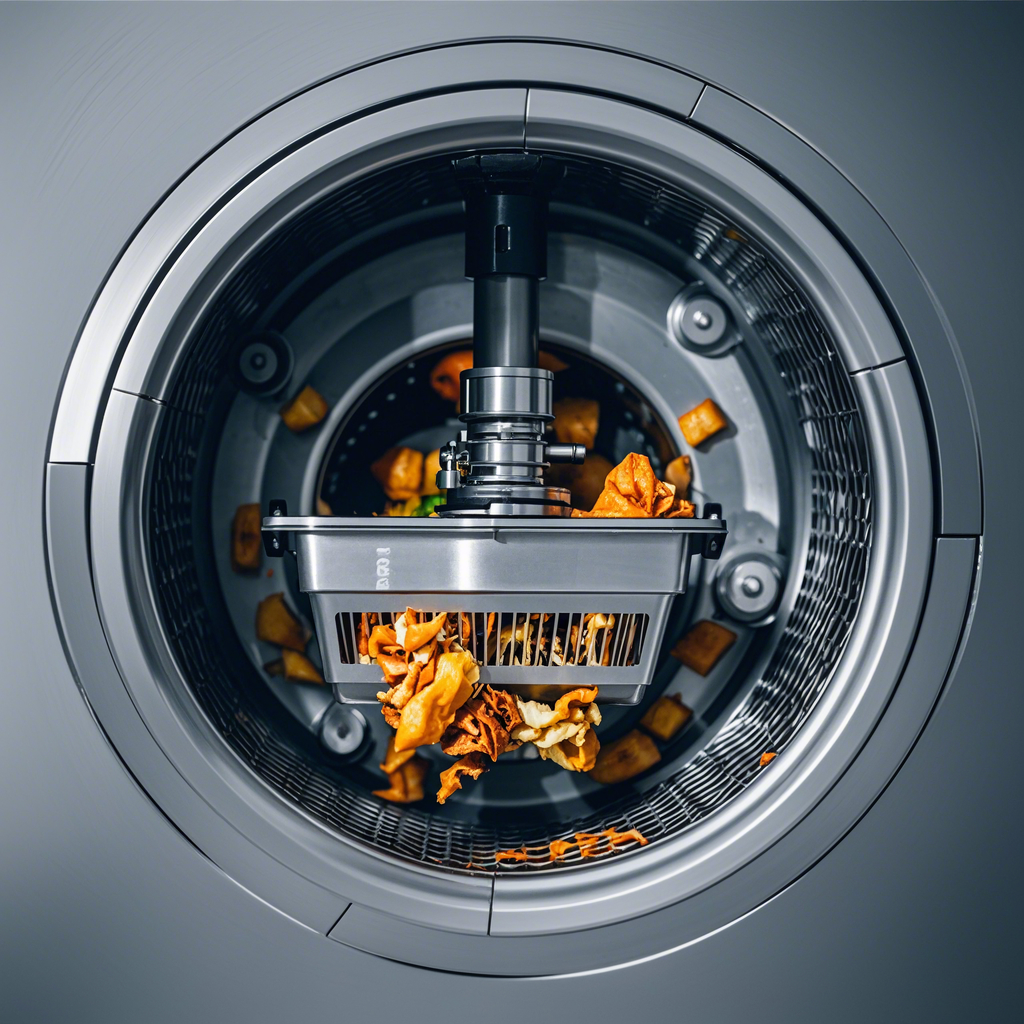

Deceleration mode: Planetary gear reduction (Planetary Gear), high transmission efficiency, to ensure the smooth operation of the seat.

Speed ratio: 10:1-50:1 optional, adapt to different load requirements.

Self-locking function: The worm gear structure ensures that the seat will not slide unexpectedly when stopped, improving safety.

The straight staircase uses a straight rail drive system, and the motor is installed in parallel with the track for stable operation.

The curved staircase adopts a gear-rack transmission system, and the motor can adapt to different trajectories to ensure that the seat passes through the curve smoothly.

Electromagnetic braking: ensures rapid braking in an emergency to prevent accidental slipping.

Limit switch: Precisely control the stopping position of the seat at both ends of the track to prevent it from rushing out of the track.

Obstacle Detection Sensor: Automatically stops when an obstacle is detected to avoid collision.

BG Motor has successfully helped customers optimize their stair lifts by providing high-torque, low-noise, stable and durable Stair Lift Motors, improving user experience and enhancing market competitiveness.

It is suitable for straight and curved stair lifts to meet the needs of different applications

Smooth operation, safe and stable, low noise, to ensure user comfort

Efficient power system to improve product life and reduce maintenance costs

BACK

BACK

BG Motor insisting on producing the best quality motors for our customers.