Client: John

Industry: Home Manufacturers

Cooperation time: 2021

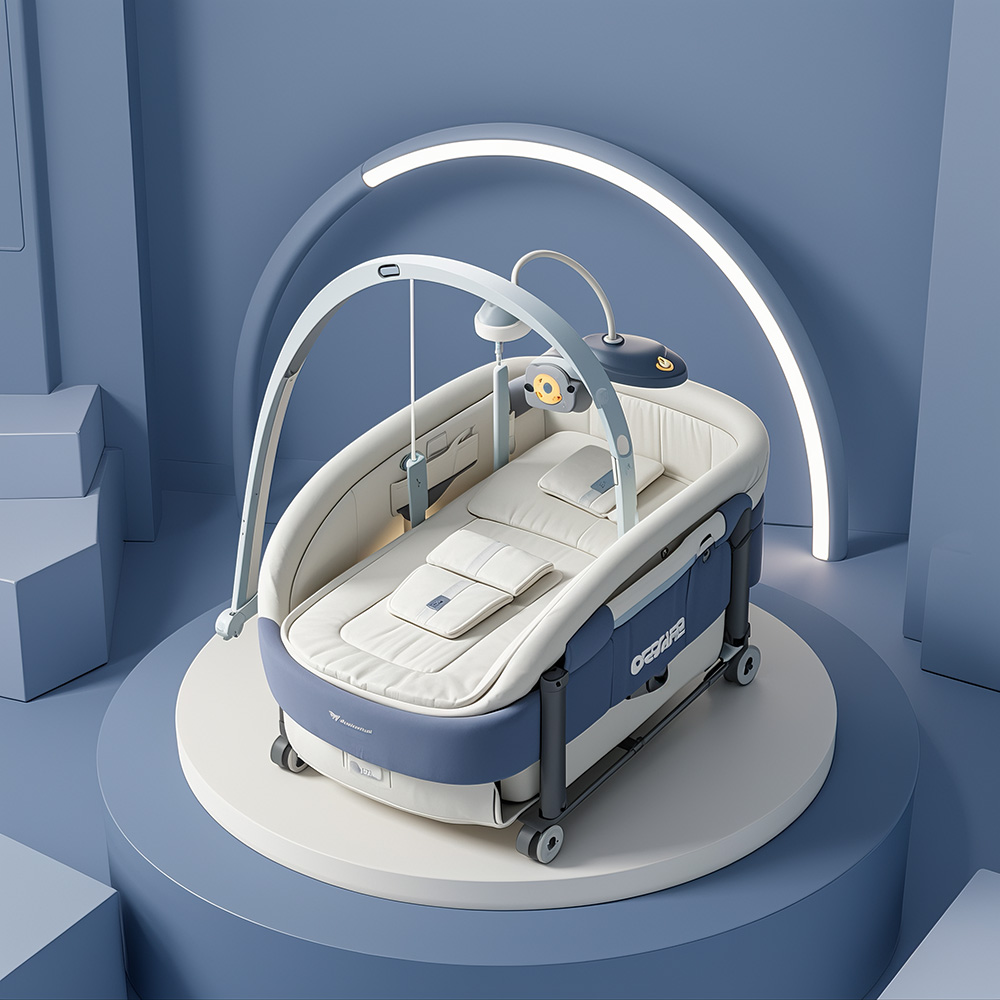

As the demand for smart devices in the home continues to increase, many home device manufacturers are looking for more efficient, durable, and energy-efficient solutions. As one of the indispensable electrical appliances in modern family life, the demand for drying clothes is rising, especially in high humidity environments. How to improve the efficiency of the dryer, extend the service life, reduce noise and vibration, and ensure the safety of the equipment at the same time has become a technical problem faced by many manufacturers.

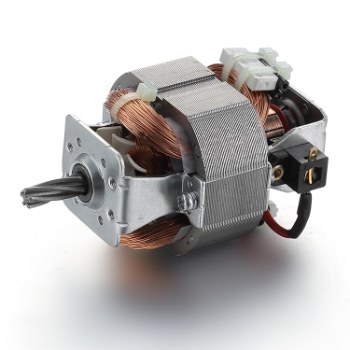

In this context, a high-performance 220V AC motor (power 800W, current 4A) is used in home dryers to provide efficient power output and reliable stability. BG Motor partnered with a U.S. home appliance manufacturer to provide a custom motor solution for the application, helping it stand out in a highly competitive market.

The main issues faced by home equipment manufacturers in the United States are as follows:

1、Durability in high-temperature environments:

Since the dryer works in a high-temperature environment for a long time, the motor needs to have sufficient heat resistance to avoid failure and shortened life caused by overheating.

2、Noise & Vibration:

In a home use environment, excessive noise and vibration can affect the user experience. Therefore, dryer motors need to be characterized by low noise and vibration.

3、Energy efficiency and stability:

In order to improve the market competitiveness of the product, the dryer motor must have the characteristics of high efficiency and low energy consumption, and at the same time have enough stability to adapt to long-term and high-load work.

4、Intelligent control and speed adjustment:

With the rise of smart homes, consumers have put forward higher requirements for the intelligent control function of dryers. The motor must support adjustable speed control to adapt to different drying needs.

In order to solve these problems, BG Motor provided the following technical solutions for the project:

Using high-quality insulation materials and an optimized cooling system, the 220V AC motor provided by BG Motor can operate stably for a long time in a high-temperature environment, ensuring that the equipment will not suffer from performance degradation or failure due to overheating.

The motor has a high degree of protection (e.g. IP65), which effectively prevents the ingress of water vapor and dust and prolongs the service life of the motor. In addition, the sealing design is adopted to avoid damage to the motor from the external environment and ensure the stability and reliability of the motor.

BG Motor's AC motors significantly reduce operating noise and vibration by optimizing gear design and using balanced rotor technology. This design ensures that the dryer remains silent during home use, providing a more comfortable user experience.

The motor adopts high-efficiency design to ensure the maximization of power conversion, reduce unnecessary energy loss, and meet the needs of modern household equipment for energy conservation and environmental protection. The stability of the motor enables the dryer to maintain continuous and stable operation under high load conditions.

The AC motor supports an intelligent control system that can automatically adjust the speed according to different drying needs, providing multi-gear adjustment options. This allows consumers to choose the most suitable working mode according to different clothing and drying conditions, increasing the flexibility and convenience of use.

As the project progresses, BG Motor and the U.S. home equipment manufacturer plan to continue to optimize the motor design to meet changing market needs and consumer preferences. Follow-up cooperation plans include:

Continuous improvement of product performance

The efficiency, durability and intelligent control functions of the motor are continuously optimized to further enhance the market competitiveness of the dryer.

Extended product line

In addition to continuing to provide motor solutions for home dryers, BG Motor also plans to apply this motor to more home appliances, such as washing machines and small household appliances, to meet the growing demand for smart home devices.

Customer Support & Training

Comprehensive after-sales support, including regular maintenance advice, training on intelligent control systems, and equipment optimization services, ensures that customers can make better use of all the functions of the dryer.

Energy saving and environmental protection upgrades

In future product iterations, BG Motor plans to further improve the energy-saving performance of the motor, strive to achieve higher energy efficiency standards, and comply with increasingly stringent environmental regulations around the world.

BACK

BACK

BG Motor insisting on producing the best quality motors for our customers.