In most cases,universal motor, also known as Single-phase series motor, are known for their common principle of excitation windings and armature windings, so what is the deeper relationship between them from the surface to the essence, you are welcome to discuss with BG Motor.

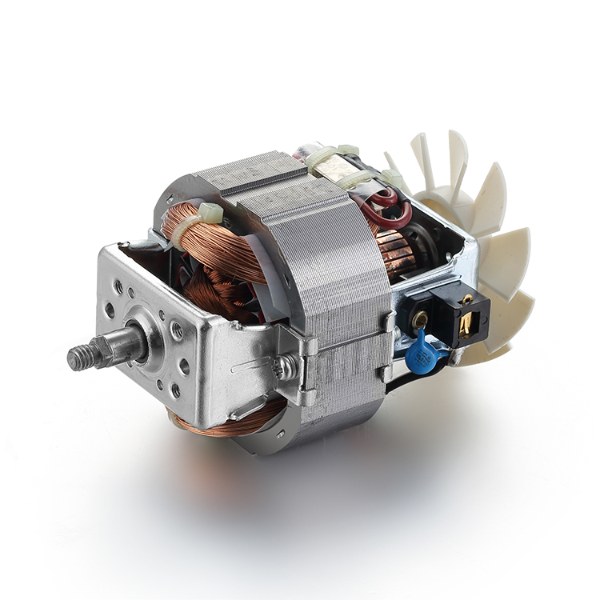

A universal motor is a small motor that can operate on both direct current and alternating current power sources, and is widely used in household appliances and portable tools. This motor is characterized by simple structure, high starting torque, and high speed, and is suitable for scenarios with large load changes.

Single-phase series motors are called universal motors because of their ability to operate on both AC and DC power, making them "general-purpose" motors.

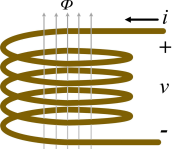

When the motor is energized, the magnetic field generated by the stator winding interacts with the current in the rotor winding to generate torque and drive the rotor to rotate.

During the rotation process, the commutator constantly changes the current direction to ensure that the rotor continues to rotate.

Through the interaction between the magnetic field and the current, the electrical energy is converted into mechanical energy to drive the external equipment to work.

Simple and compact structure: The structure of single-phase series motor is relatively simple, there is no complex control system, and it is easy to maintain.

High starting torque: Due to the characteristics of the series motor, it can generate large torque when starting, which is very suitable for application scenarios that require high starting load.

Wide range of speed regulation: The speed of the single-phase series motor can be adjusted in a wide range by changing the power supply voltage

Low cost: Compared with other types of motors, the manufacturing cost of single-phase series motor is low, which is suitable for large-scale production and application.

And it is mainly used in household and industrial application scenarios such as vacuum cleaners, juicers, coffee machines, electric drills, and chainsaws.

The production of general-purpose motors has to go through complex steps, starting from the rotor assembly, it has to go through the detection of the shaft, pressing to the rotor core, pressure commutator, winding, slot wedge, semi-finished product testing, dripping paint, finishing turning, balancing, finished product testing, finale support, etc., and finally the stator after the inspection is assembled together.

Compared with other types of motors, the structure of general-purpose motors is relatively simple, there is no complex control system, it is easy to maintain, and it has a high starting torque, which is very suitable for the use of high starting loads, and has a wide range of speed regulation, which can be carried out by changing the power supply voltage. Single-phase series motors have a low manufacturing cost and are suitable for large-scale production and applications.

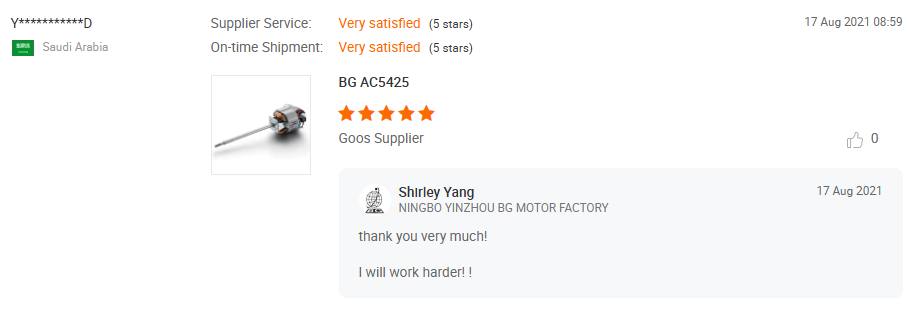

In addition to technology research and development and production, our wide range of services has been recognized by customers

BACK

BACK

In February 2025, BG Motor ushered in the traditional Lantern Festival celebrati…

The new year has begun, and BG Motor is officially back to work! After a refresh…

Dear Customers, Partners and Employees,On the occasion of the Spring Festival, B…

BG Motor, Ningbo, China, January 9, 2025 – As the festivities of Christmas and N…

At this juncture of saying goodbye to the old and welcoming the new, all BG Moto…

Originally commemorated the birth of Jesus, Christmas has become a powerful cult…