Industrial Automatic Cutting Machine

Client: Mr. Choi

Country: the republic of Korea

Industry: The clothing industry

Cooperation time: from 2012 to now

In March 2012, the customer found us through China's import agents. Their company is a professional manufacturer specializing in the production of sewing machines and automatic cutting machines;

Before they found our company, they had been importing all the motors from Japan, which was expensive and expensive. They hope to find a reliable motor manufacturer in China, but the price can be more competitive; Through the understanding and feedback of China's import agents in the Chinese market, BG motor's motors are specialized in the production of motors in this field, which has a history of more than 20 years and is a leader in the industry.

What they need:220V 60Hz 10000rpm High Speed Larger Torgue AC Motor

1. the motor requires as like two peas: the motor used before is Japanese, and the motor we are required to produce must be the same as the motor produced in Japan, and only better.

2. When the output shaft of the motor is running, there shall be no movement and clearance; Because it is used to cut cloth, if the shaft moves, the shape of cloth cut by the blade in the cutting process will not meet the requirements.

3. The shell color of the motor shall be blue.

4. The noise shall be less than 70dB.

5. Service life: more than 1000 hours; (for high-speed motors, it is still very difficult for the motor speed to reach 1000 hours without replacing the carbon brush)..

With regard to the above problems mentioned by customers, our technical team is still very confident that we can fully achieve them because we have been professional in this industry for more than 20 years. We have sufficient technical strength, and we can say with confidence that the quality of the motors we produce will definitely meet the standard.

1. Our technical engineers are very meticulous. When Korean customers came to our company for negotiation, we reached a high degree of cooperation intention.

Our technical engineers went to the production site of Korean customers to understand the actual production of the machine and learned a lot of details in detail.

2. After the engineer returned to the company, the technical team held a meeting and made a detailed deployment for the motor product required by the customer. We listed all the quality problems that may be caused by the motor in the production process and made specific improvement methods.

3. With regard to the service life of the motor, we have carried out structural reform on the length of the motor carbon brush holder, which also ensures that the length of the brush is sufficient; We have carried out a 24-hour life test and comparison on 100 kinds of brushes and selected the final carbon brush.

4. As for noise, we have carefully studied and compared the materials and machining accuracy of the commutator, which meets the requirements of customers for low noise and low current.

After receiving the samples, the customer was very satisfied and told us that the quality of the products was better than that of the motors they produced in Japan.

BG motor amazed me. Their meticulous working attitude and dedication to work are to use their practical actions to improve the quality of products and meet our needs. I didn't expect such a responsible manufacturer in China. I am very satisfied with BG motor's engineers and business personnel. They are also very timely in product delivery, which ensures that our machines can be delivered to our own customers in time.

--Mr.Choi(CEO)

BACK

BACK

-

Read More

Read MoreBLDC 86MM --- agv robot

-

Read More

Read MoreRobotic arm

-

Read More

Read MoreLaser paint film meter

-

Read More

Read MoreDiaphragm pump

-

Read More

Read MoreOutdoor Siren

-

Read More

Read MoreVacuum Cleaner

-

Read More

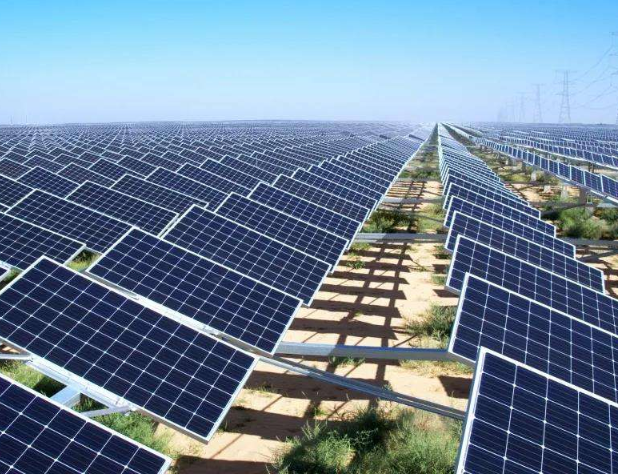

Read MoreIndustrial Equipment--Photovoltaic solar panel

-

Read More

Read MoreIndustrial Equipment-Storage and logistics AGV trolley

-

Read More

Read MoreElectric trolley for breeding

-

Read More

Read MoreIndustrial Equipment-Small Electric Fabric Cutter