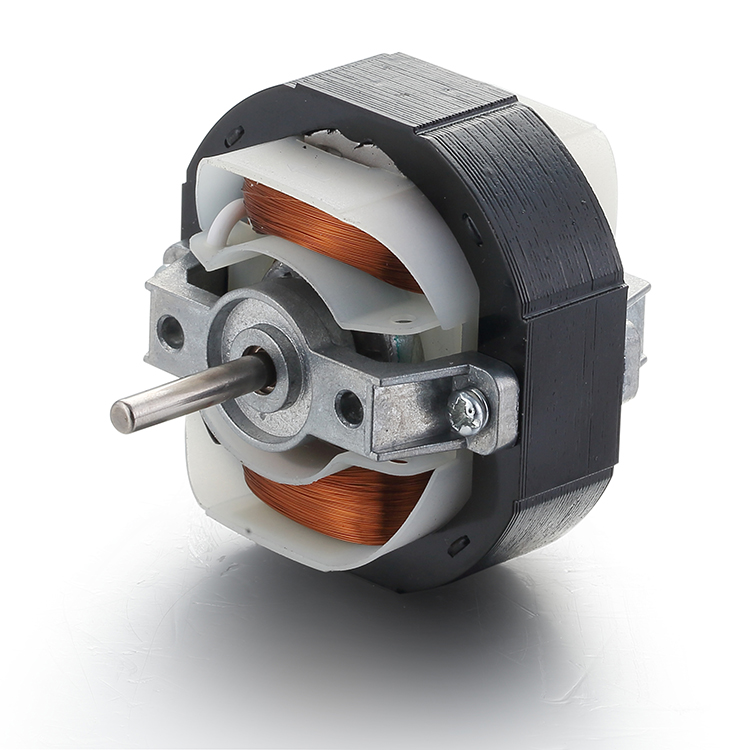

Description

| Environmental Conditons | —20℃~50℃ | Number of Phases | Single |

| Rotation Direction | CW/CCW | Insulation Class | B-H |

| Noise | ≤65dB | Protection Class | IP00 |

| Work Condition | S2.S3 |

Advantages

- 01Simple Structure:The design of the shaded pole motor is very simple, there are no brushes or commutators, which reduces mechanical wear and failure points.

- 02Materials:

100% pure copper wire or 30% pure copper wire + 70% aluminum wire, bearing: ball bearing or oil impregnated bearing.

- 03High Reliability:The structure is simple and there is no brush, and the shaded pole motor is not easy to fail during operation, and has high reliability.

- 04Small Size:Shaded pole motors are usually designed to be compact and suitable for applications where space is limited.

05Easy To Manufacture And Maintain:

Due to its simple design and small number of parts, the manufacturing process of shaded pole motors is relatively easy and simple to maintain.

06Stable Low-Speed Performance:

The shaded pole motor has good stability when running at low speed, which is suitable for applications that require stable low-speed operation.

07Low Noise:

There are no brushes and commutators, and the noise generated by the shaded pole motor during operation is low.

08Simple Start-Up:

The shaded pole motor can be started directly by plugging in the power supply, without the need for additional starting equipment.

Motor Technical Data

| RATED LOAD | NO LOAD | STALL | |||||||

| Voltage | Voltage | Power | Speed | Torque | Current | Speed | Current | Torque | Current |

| V | v | w | rpm | N.m | A | rpm | A | N.m | A |

| BG YJ6110 | 110 | 10 | 2500 | 0.04 | 0.13 | 2850 | 0.03 | 0.11 | 0.39 |

| BG YJ6112 | 220 | 14 | 2500 | 0.05 | 0.09 | 2850 | 0.02 | 0.16 | 0.27 |

| BG YJ6116 | 110 | 18 | 2500 | 0.07 | 0.23 | 2850 | 0.05 | 0.21 | 0.7 |

| BG YJ6120 | 220 | 21 | 2500 | 0.08 | 0.14 | 2850 | 0.03 | 0.24 | 0.41 |

| BG YJ6125 | 110 | 25 | 2500 | 0.1 | 0.32 | 2850 | 0.06 | 0.29 | 0.97 |

| BG YJ6135 | 220 | 30 | 2500 | 0.11 | 0.19 | 2850 | 0.04 | 0.34 | 0.58 |

| We can also customize products according to customer requirements. | |||||||||

| Spur Gear Motor Technical Data-BG | ||||||||

| Reduction ratio (1:xx) | 36 | 66 | 94 | 155 | 219 | 322 | 456 | 833 |

| Rated speed (rpm) | 69 | 38 | 27 | 16 | 11 | 8 | 5.5 | 3 |

| Rated torque (N.m) | 2.41 | 4.4 | 6.2 | 8 | 8 | 8 | 8 | 8 |

Mechanical Dimensions

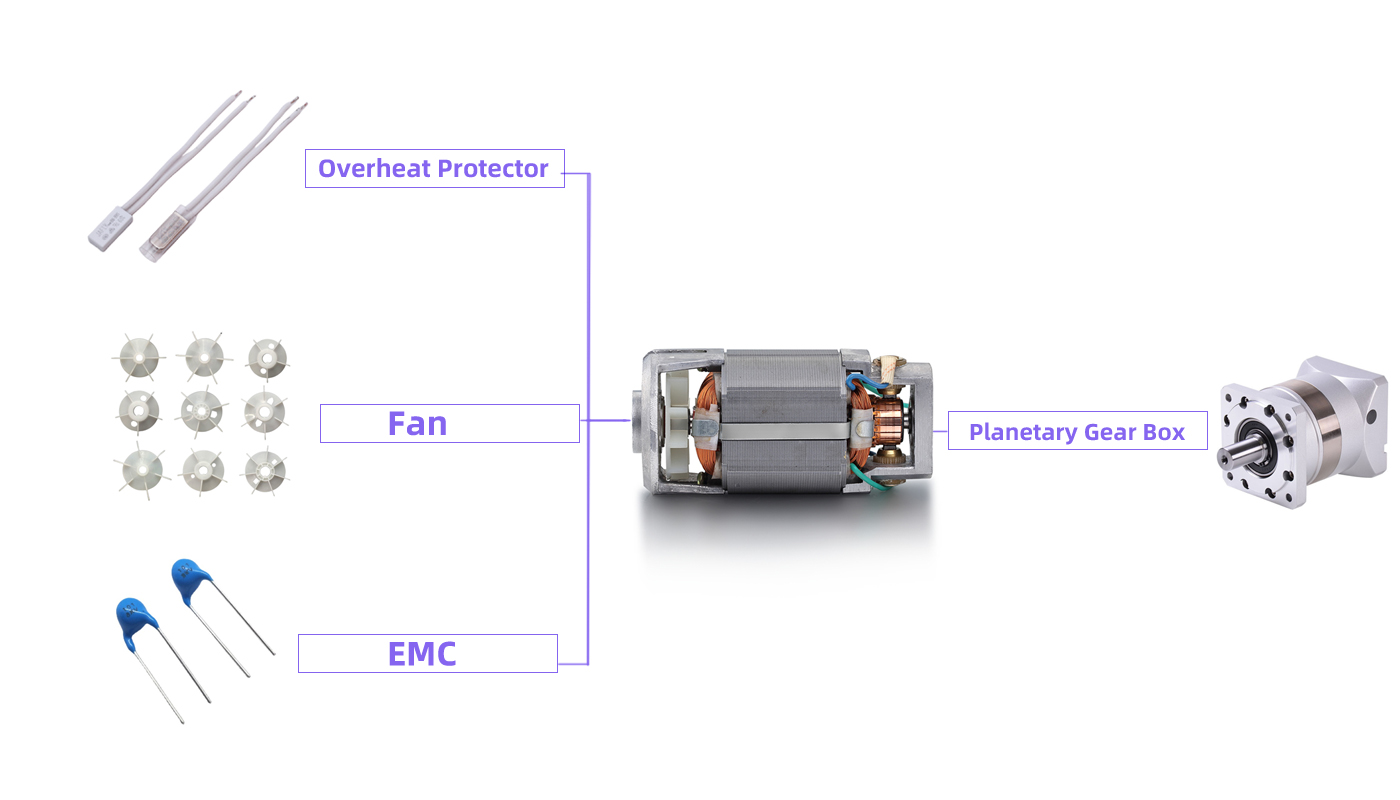

Customizable solutions

Can provide custom voltage, electrical performance, circuit, etc.

And shaft, installation flange, lead wire, high-temperature class, drive, etc.

If you have any other needs, please contact our sales engineers.

Parts

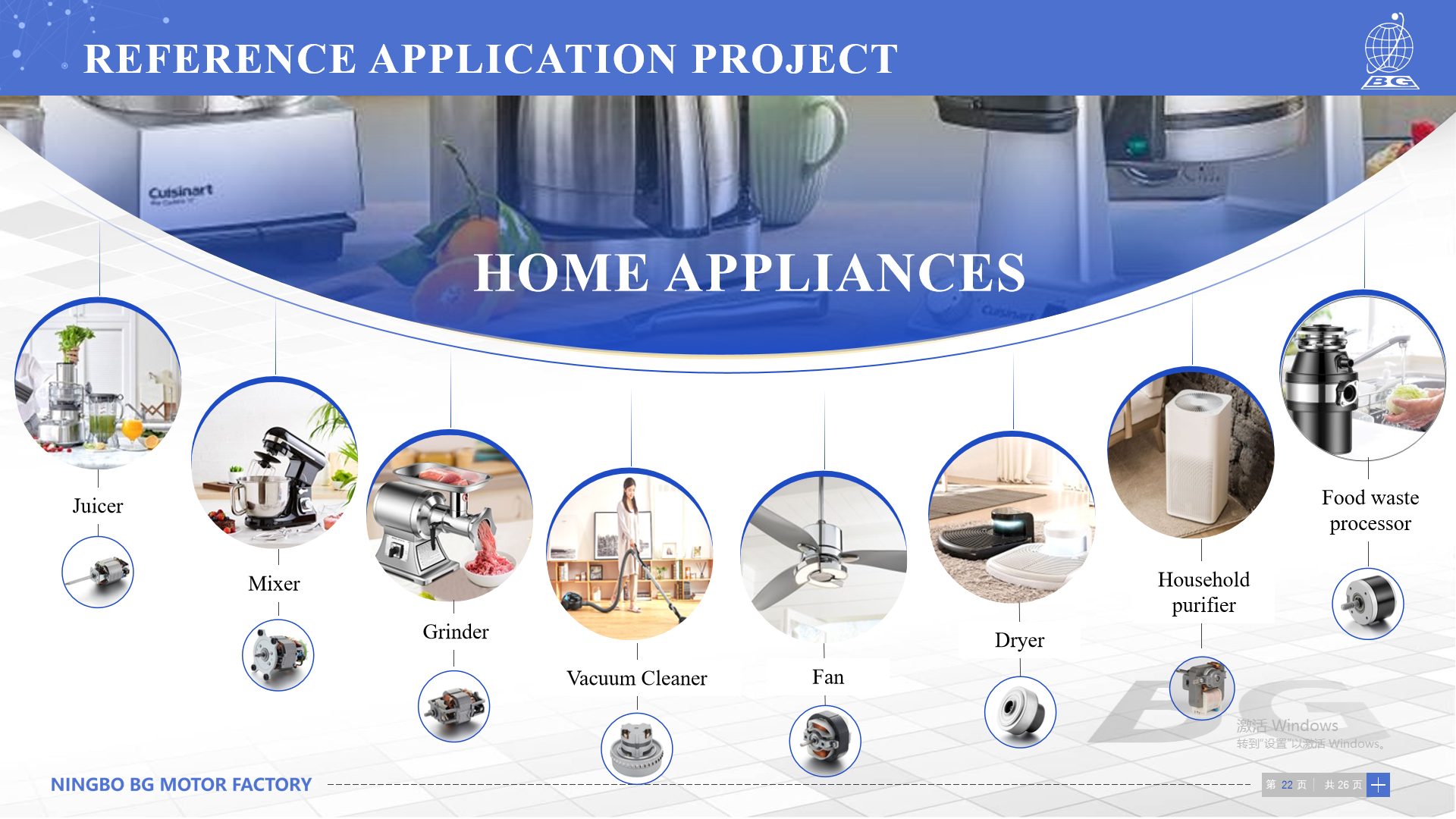

Applications

Motor Selection Details

01Application Scenarios:

Understand the specific application environment and use of motors, such as toys, power tools, home appliances, industrial equipment, etc.

- 02Materials:

100% pure copper wire or 30% pure copper wire + 70% aluminum wire, bearing: ball bearing or oil impregnated bearing

03Power Requirements:

Determine the operating voltage and frequency of the motor. Shaded pole motors are usually single-phase motors, so it is necessary to know the customer's power specifications (e.g. 220V, 50Hz or 110V, 60Hz).

04Power And Torque Requirements:

According to the application scenario, the final speed and power required by the motor will also be different depending on the weight of the blade, and it is best to provide the diameter and weight of the blade.

05Speed Requirements:

Understand the specific requirements of customers for motor speed. Shaded pole motors are usually fixed-speed motors, but the rotational speed may vary from model to model.

06Physical Size Limitations:

Confirm the space constraints of the motor at the time of installation, including the diameter, length, and mounting method of the motor.