Description

| Environmental Conditons | —20℃~50℃ | Number of Phases | / |

| Rotation Direction | CW/CCW | Insulation Class | B-H |

| Noise | ≤65dB | Protection Class | IP40 |

| Work Condition | S1.S2.S3 |

Advantages

- 01High Efficiency:

Due to the brushless design that eliminates frictional losses between the brushes and the commutator, BLDC motors are generally more efficient than brushed motors, especially under high load conditions.

- 02Low Maintenance:

Since there are no brushes, BLDC motors do not need to be replaced regularly, reducing maintenance costs and time.

- 03High Reliability And Long Life:

The brushless design reduces mechanical wear and improves the reliability and service life of the motor

- 04High Power Density:

BLDC motors can provide high power output in a small volume, which is suitable for application scenarios where space is limited.

05Precise Speed And Position Control:

Due to the electronic commutation mode of BLDC motors, precise speed and position control can be realized, which is suitable for applications that require high-precision control.

06Quiet Operation:

The brushless motor operates with low noise because there is no frictional noise of the brushes and commutators.

07High Speed:

BLDC motor can achieve high speed, suitable for high-speed applications, such as power tools and high-speed rotating equipment.

08Better Thermal Management:

The stator of brushless motors is usually surrounded by the rotor, which has a better heat dissipation effect and helps to improve the efficiency and life of the motor.

Motor Technical Data

| Model | Voltage | No-load | Rated Load | Stall | Body Length | ||||||

| Speed | Current | Power | Speed | Torque | Current | Torque | Current | ||||

| V | rpm | A | W | rpm | Kg.cm | A | Kg.cm | A | L:mm | ||

| BG-775DC-1235S | 12 | 4600 | 0.60 | 32 | 3500 | 0.90 | 4.4 | 2.70 | 13.20 | 66.5 | |

| BG-775DC-2445S | 24 | 6000 | 0.30 | 40 | 4500 | 0.90 | 2.2 | 2.70 | 6.60 | 66.5 | |

| Model | Reduction ratio | 1:X | 1:16 | 1:32 | 1:48 | 1:89 | 1:120 | 1:169 | 1:225 | 1:326 | |

| BG-50ZYT-1237S-XK | NO-load speed | rpm | 308 | 154 | 103 | 55 | 41 | 29 | 22 | 15 | |

| Rated speed | rpm | 231 | 116 | 77 | 42 | 31 | 22 | 17 | 11 | ||

| Rated torque | N.m | 0.89 | 1.78 | 2.66 | 4.94 | 6.66 | 9.38 | 12.21 | 18.09 | ||

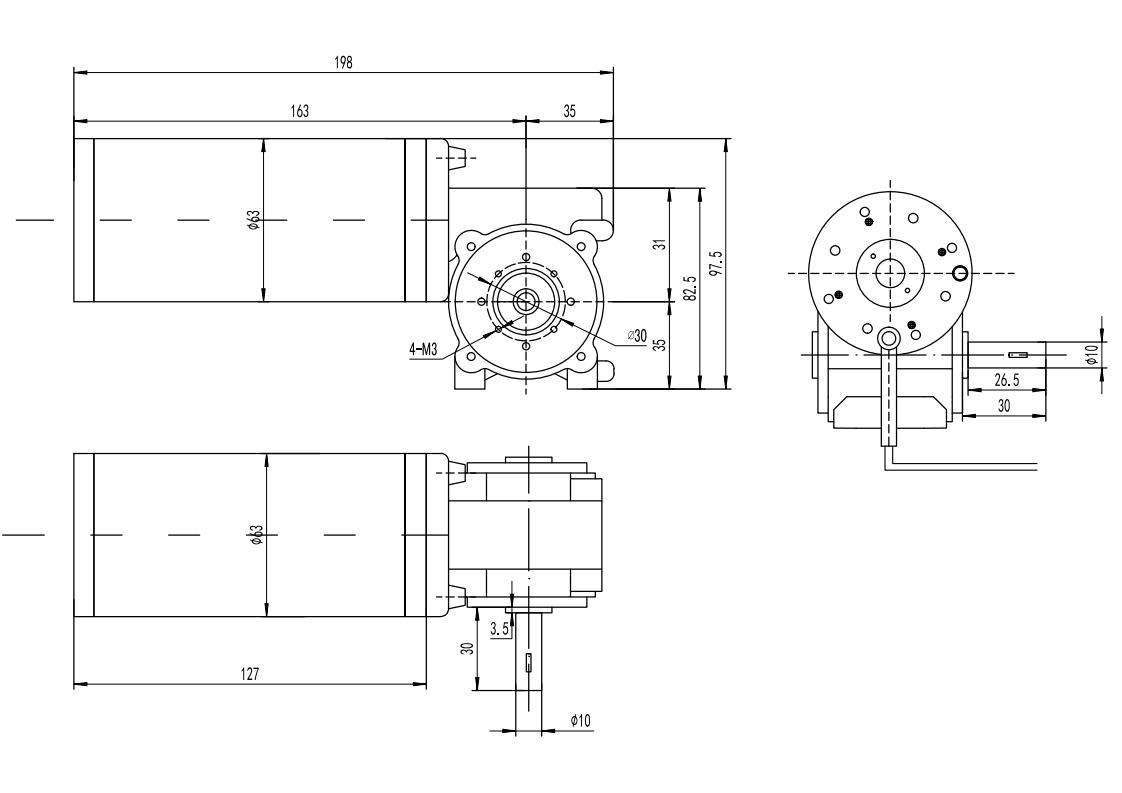

Mechanical Dimensions

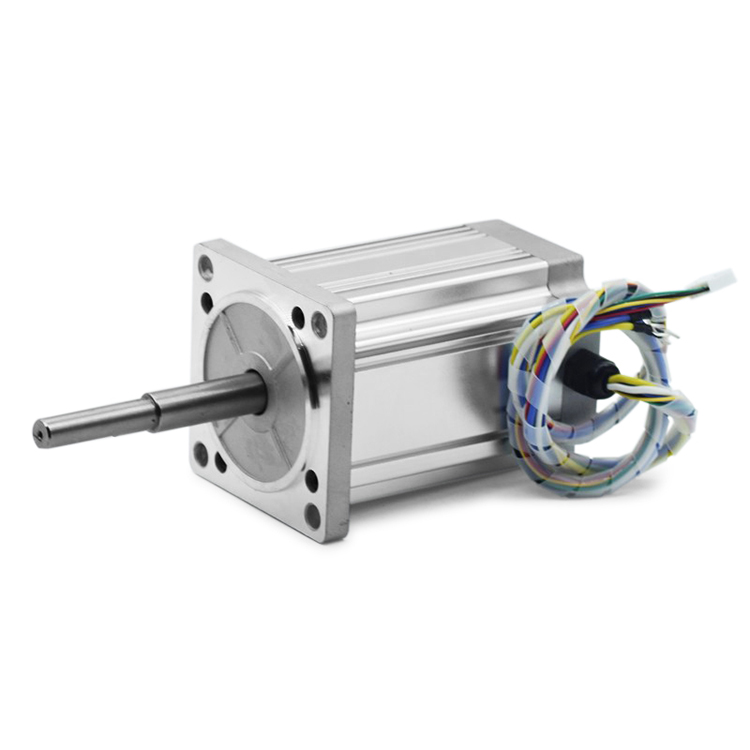

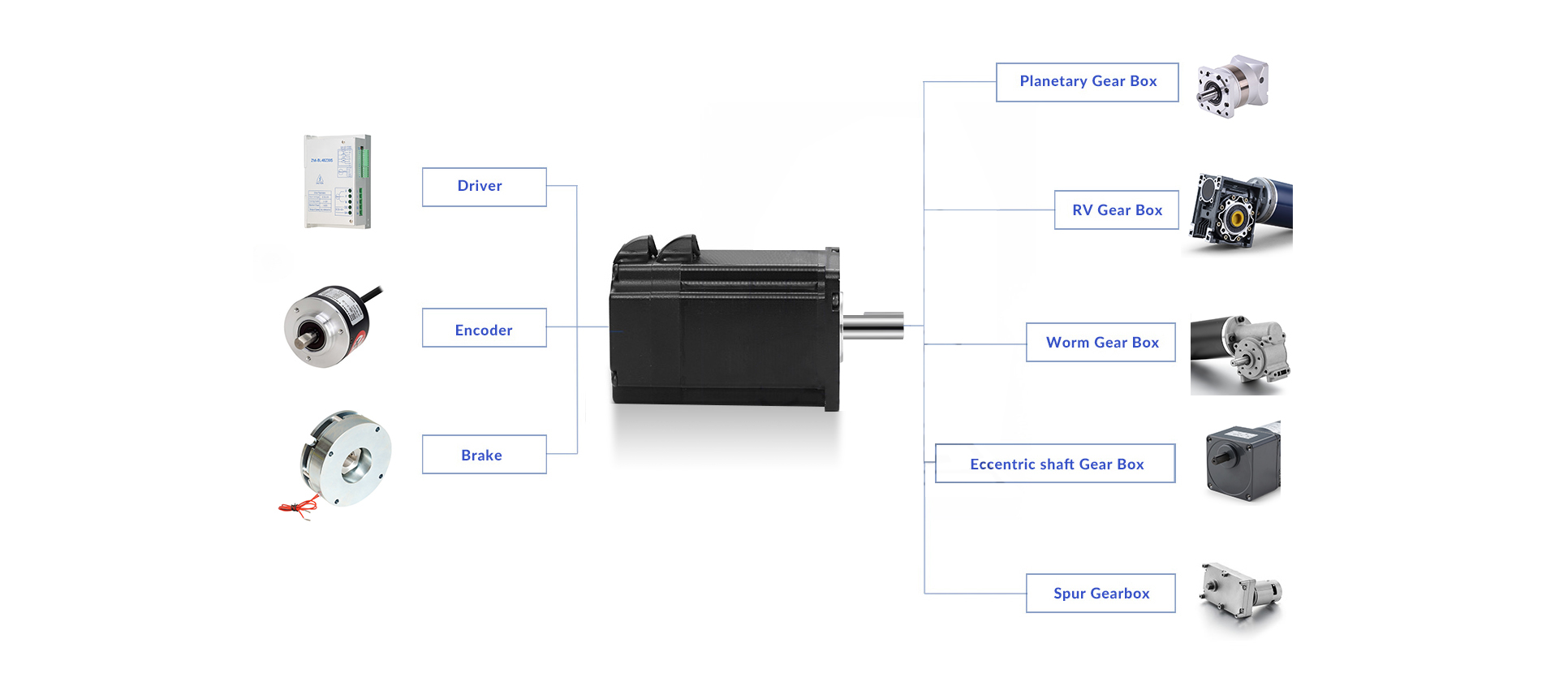

Customizable solutions

Can provide custom voltage, electrical performance, circuit, etc.

And shaft, installation flange, lead wire, high-temperature class, drive, etc.

If you have any other needs, please contact our sales engineers.

Parts

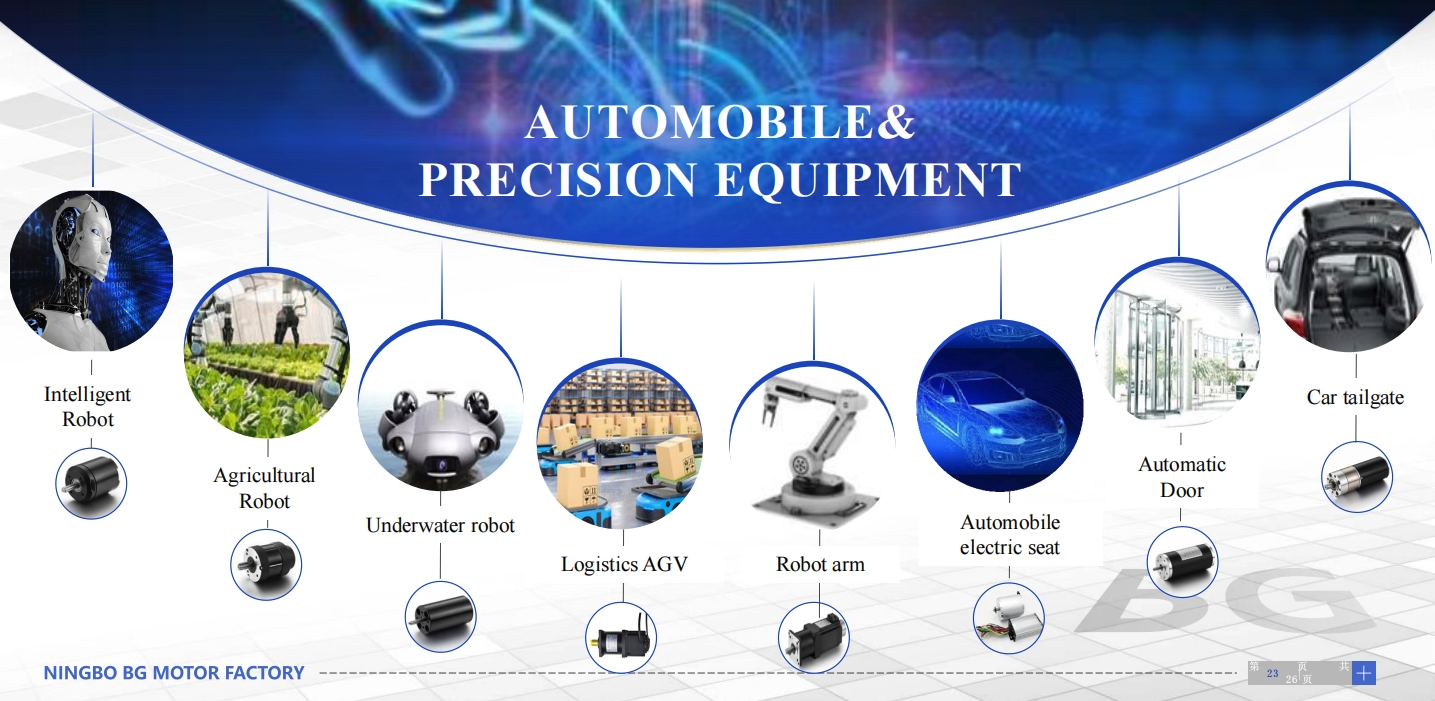

Applications

Motor Selection Details

01Application Requirements:

Specific application scenarios (e.g., industrial robots, drones, power tools, AGVs, medical equipment, etc.)

Required operating environment (e.g., temperature range, humidity, dust and water resistance, etc.)02Motor Specifications:

Rated voltage and currentRated power and peak poweSpeed range (RPM, rpm)Torque requirements (rated torque and maximum torque)Efficiency requirements

03

Dimensions & Weight:

Dimensions (diameter, length, etc.)Weight Limit

04Control Requirements:

Control type (e.g. open-loop control, closed-loop control)、Type of sensor required (e.g. Hall sensor, encoder)

05Connection & Installation:

Type and size of shaft、Installation method (flange mounting, base mounting, etc.Wiring method and connector type.

06Power Requirements:

Power supply type (DC power, battery, AC power, etc.)Rated voltage range and allowable voltage fluctuations.

07Environmental Conditions:

Ingress protection (e.g. IP rating)、Operating temperature range、Operating temperature range、Operating temperature range.

08Other Special Requirements:

Noise level (for noise-sensitive applications, choose a low-noise, low-vibration motor).

Electromagnetic Compatibility (EMC)、Lifetime and reliability requirements.