Model Number: BG 43L300X001

Range of Power: 300-600W

Range of Voltage:12-48V

Max. Flux: 120-150m³/h

Max. Vacuum: 18-20Kpa

Lifespan: 1200Hours

Application: Fume/Smoke extraction、Vacuum cleaner、Sprayer、Hand dryer

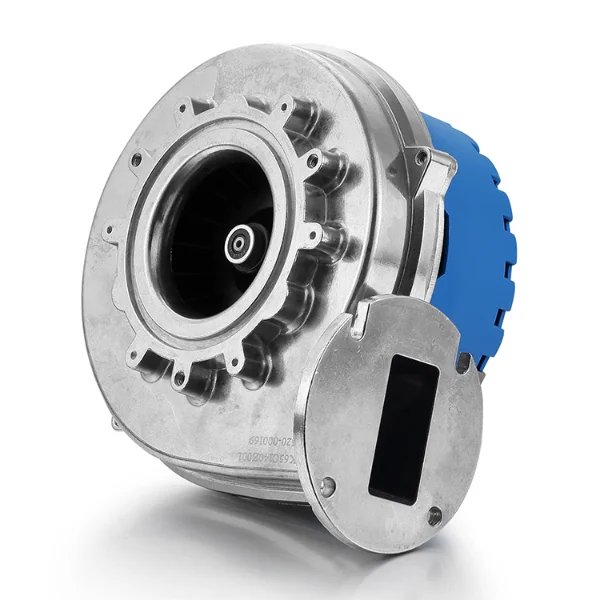

Model Number: BG73

Range of Power: 700W、1200W

Range of Voltage: 230V 50/60Hz

Max Air Flow: 300m³/h

Maximum Vacuum Presure: 7Kpa

Weight: 2.52kg

Fan System:Tangential By Pass

Application:Tangential Fume/Smoke extraction/Dust collector、Dental equipment、Packing equipment、Laser machine、Sterilizer、Environmental protection equipment、Combustion equipment、Air-purification equipment

Model Number: BG65

Range of Power: 110W

Range of Voltage: 230V 50/60Hz

Max Air Flow: 115m³/h

Maximum Vacuum Presure: 3Kpa

Weight: 1.0kg

Application: Fume/Smoke extraction、Dental equipment、Care equipment、All kinds of gas heating devices and food processing equipment

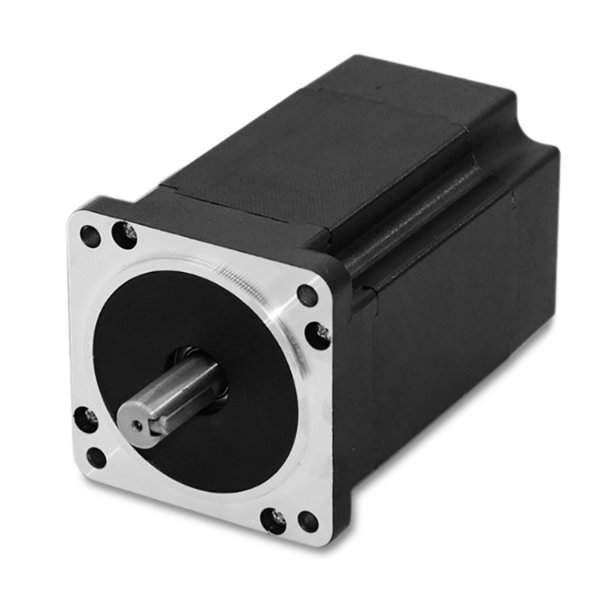

Model Number: BG 86BL115

Range of Power: 300-800W

Range of Voltage:12-310VDC

Range of Rated Speed: 1500-6000rpm

Range of Rated Torque: 0.65-2.5N.m

Lifespan: 5000-20000Hours

Model Number: BG 51C500x001

Range of Power: 300-800W

Range of Voltage:110-230VDC 50-60Hz

Maximum Flow: 130-220m³/h

Maximum Suction: 9-30Kpa

Lifespan: 1000Hours

Application: Fume/Smoke extraction、Sprayer、Hand dryer、Dental equipment、Care equipment、Laser machine

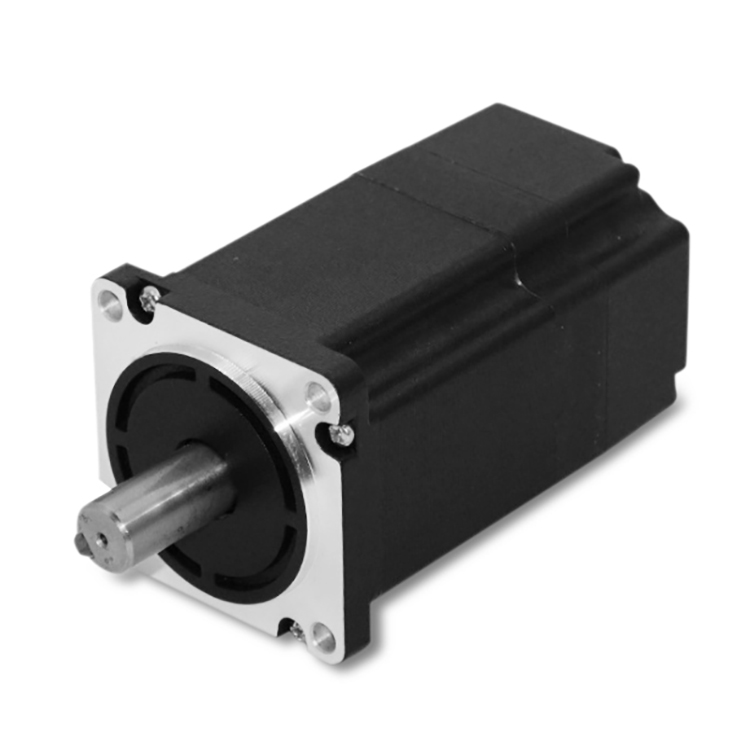

Model Number: BG 110BL140

Range of Power: 400-2000W

Range of Voltage:24-310VDC

Range of Rated Speed: 1500-4000rpm

Range of Rated Torque: 1.27-6.37N.m

Lifespan: 5000-20000Hours

Model Number: BG 57BL01

Range of Power: 35-200W

Range of Voltage:12-310VDC

Range of Rated Speed: 1000-6000rpm

Range of Rated Torque: 0.06-0.32N.m

Lifespan: 5000-20000Hours

Model Number: BG 86BL80

Range of Power: 300-800W

Range of Voltage:12-310VDC

Range of Rated Speed: 1500-6000rpm

Range of Rated Torque: 0.65-2.5N.m

Lifespan: 5000-20000Hours

Model Number: BG26

Range of Power:100W-300W

Range of Voltage:22.2V

Max Air Flow:80m³/h

Maximum Vacuum Presure:22.5Kpa

Weight: 0.26kg

Fan System:Through Flow

Application:Through Fume/Smoke extraction、Vacuum tool、Sprayer、Medical equipment、Handle vacuum cleaner、Packaging unit

Model Number: BG 86BL90

Range of Power: 300-800W

Range of Voltage:12-310VDC

Range of Rated Speed: 1500-6000rpm

Range of Rated Torque: 0.65-2.5N.m

Lifespan: 5000-20000Hours

Model Number: BG60

Range of Power:800W、1200W

Range of Voltage: 230V 50/60Hz

Max Air Flow: 150m³/h

Maximum Vacuum Presure: 25Kpa

Weight: 2.60kg

Fan System:Tangential By Pass

Fan System:Tangential Fume/Smoke extraction、Sprayer、Dental equipment、Care equipment、Laser machine、Sterilization equipment

Model Number: BG 80

Range of Power: 200-600W

Range of Voltage:12-310VDC

Range of Rated Speed: 1500-6000rpm

Range of Rated Torque: 0.64-1.7N.m

Lifespan: 5000Hours

Model Number: BG36

Range of Power: 350W

Range of Voltage: 24V

Max Air Flow: 71.4m³/h

Maximum Vacuum Presure: 17Kpa

Weight: 0.90kg

Fan System: Tangential By Pass

Application: Tangential Fume/Smoke extraction、Vacuum tool、Fuel cell、Medical equipment、Handle vacuum cleaner

Model Number: BG 60BL01

Range of Power: 150-400W

Range of Voltage:12-310VDC

Range of Rated Speed: 1500-6000rpm

Range of Rated Torque: 0.48-1.27N.m

Lifespan: 5000-20000Hours

Model Number: BG57

Range of Power: 600W、1200W

Range of Voltage: 230V 50/60Hz

Max Air Flow:174m³/h

Maximum Vacuum Presure: 14.1Kpa

Weight: 2.5kg

Fan System:Tangential By pass,2 Stage

Application:Fume、Sprayer、Sterilizer、Medical equipment、Laser machine、Printing machine、Lithium electricity equipment

Model Number: BG 42BL60

Range of Power: 25-105W

Range of Voltage:12-48VDC

Range of Rated Speed: 1500-6000rpm

Range of Rated Torque: 0.06-0.33N.m

Lifespan: 5000-20000Hours

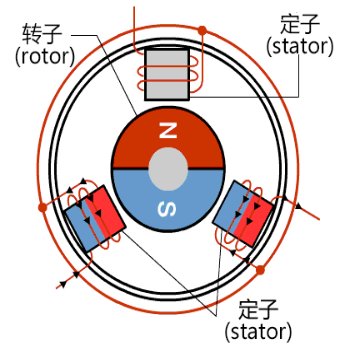

Brushless DC Motor (BLDC) is a motor that uses an electronic controller to replace the mechanical commutator in a traditional brushed motor to control the rotation of the motor rotor.

Brushless motors are DC motors that do not use brushes and commutators. Due to their high efficiency, controllability, low noise, and long life, they are widely used in various precision instruments and equipment, such as industrial automation, medical centrifuges, smart home devices, etc.

The stator is the stationary part of the motor, usually composed of multiple electromagnetic coils. It is the main source of magnetic field for BLDC motors. By passing electricity through the stator coil, an alternating magnetic field is generated to drive the rotor to rotate.

The stator is usually made of laminated silicon steel sheets to enhance the concentration of the magnetic field and reduce energy loss.

The rotor is the rotating part of the motor, usually made of permanent magnetic material (such as neodymium iron boron magnets). The rotor and stator interact through the magnetic field to achieve rotation.

The rotor of the brushless motor has no brushes, which reduces wear and heat generation, thereby greatly extending the service life of the motor.

Electronic Commutation System (Electronic Commutator):

The commutation of the brushless DC motor is completed by an external electronic controller. The actual position of the rotor is determined by a sensor that detects the rotor position (such as a Hall sensor), and then the electronic switch is controlled according to the position and speed information to ensure the correct switching of the current in the stator coil, thereby controlling the rotation direction and speed of the rotor.

This electronic control method avoids the physical contact between the brush and the commutator, thereby reducing friction loss and noise.

The brushless motor needs to be matched with a controller to achieve precise control and commutation. The controller controls the speed, torque and position of the motor by providing current to the stator winding and adjusting the magnitude and direction of the current.

The main task of the controller is to adjust the operating state of the motor according to the sensor feedback to ensure that the motor runs smoothly and efficiently.

The Hall sensor is used to detect the angle and position of the rotor and provide feedback signals to the controller. Through the Hall sensor, the controller can accurately control the timing of current switching, thereby ensuring precise control of the motor at various positions.

Bearings are used to support the rotor and allow it to rotate smoothly. Brushless DC motors usually use high-precision bearings to ensure that the motor can maintain low friction and stable operation when running at high speed. The working principle of brushless DC motors is based on the law of electromagnetic induction. The current on the stator generates an alternating magnetic field, and the permanent magnets on the rotor interact with the magnetic field of the stator to generate torque. When the direction and magnitude of the current in the stator coil change, the direction and magnitude of the magnetic field also change, thereby driving the rotor to rotate continuously. In brushed motors, the commutator contacts the rotor through brushes to control the switching of current; in brushless motors, electronic controllers and Hall sensors replace this physical structure to achieve a more efficient and frictionless commutation process.

· Long life: Since there is no wear of brushes, the service life of brushless motors is much longer than that of brushed motors.

· Low noise and low vibration: Brushless motors have no friction between brushes and commutators, so they are quieter and vibrate less during operation.

· High efficiency: There is no brush friction loss, and the rotor is made of permanent magnet material, which has high energy efficiency.

· Low maintenance requirements: Since there are no brushes, the complexity and frequency of motor maintenance are reduced.

· Higher power density: Brushless motors can usually provide more power in a smaller volume, which is suitable for applications with compact space requirements.

Comparison between brushless and brushed motors In general, brushless motors have longer life, higher efficiency, stronger precision, lower noise, lower maintenance costs, and more intelligent and extensive applications, making them the first choice for modern production and manufacturing.

Household appliances: such as vacuum cleaners, air conditioners, electric fans, etc. ·

Power tools: such as electric drills, electric screwdrivers, etc.

Robots: used to drive robot joints, electric wheels, etc.

Electric vehicles: motors used to drive electric vehicles.

UAVs: as drive motors for flight power systems.

Brushless motor fans: silent, energy-saving and environmentally friendly, more suitable for home and office use

Large equipment: brushless motors are the first choice for the production and manufacturing of various large equipment because of their precision performance and high efficiency.

Brushless DC motors have gradually become the preferred motor type for many industries and applications due to their high efficiency, low noise, long life and good speed regulation characteristics.

BG motor was established in 1994 and is a motor manufacturer and supplier integrating R&D, production and sales.

BG Motor is supported by quality and driven by technology. Strict quality control and customized solutions have won us a lot of praise from customers. In the future, we will continue to be committed to becoming the most trusted motor manufacturer in the world.

Over the past few decades, the company has been constantly exploring and researching. So far, BG Motor has developed into a manufacturer with 12,000 square meters of factory buildings and fully automatic production lines, making the cost of products more advantageous. The main products are DC brushless motors, DC brush motors, AC motors, worm gear motors, vacuum cleaner motors, robot motors and motor accessories.

In the field of brushless motors, we have a number of patents and a professional R&D team, providing customized services, striving to provide customers with the most satisfactory motor solutions, and becoming the world's most trusted motor manufacturer.

BG motor has always been committed to doing it with heart, seeking perfection, daring to take responsibility, and honesty as its core values. Turning a better life, continuing to provide customers with the mission of providing customers with the best motor solutions and services. In the future, we will continue to forge ahead, just as the founder's original wish, insisting on providing customers with the highest quality motors.