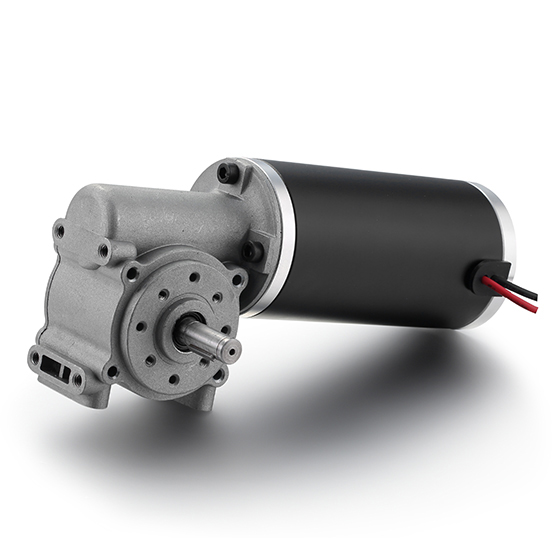

Model Number: BG 110ZYT218

Range of Power: 180-600W

Range of Voltage:12-220VDC

Range of Rated Speed: 15-150rpm

Range of Rated Torque: 13-130N.m

Lifespan: 2000Hours

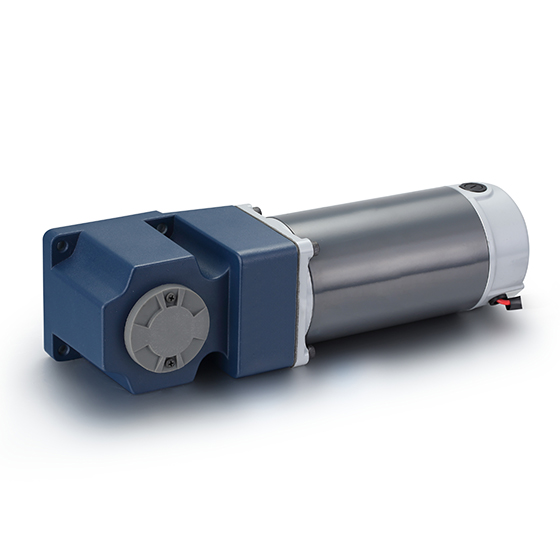

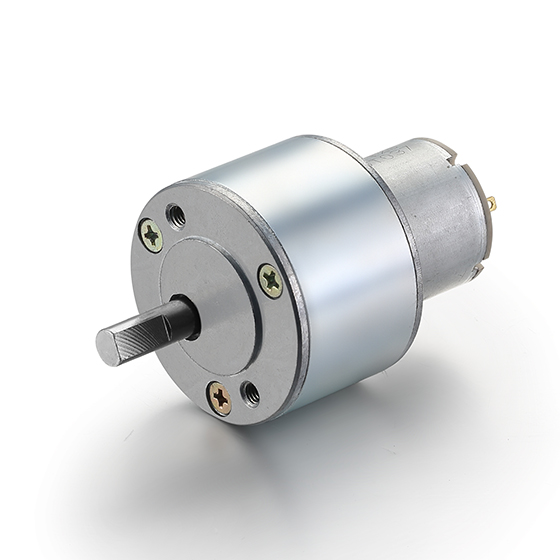

Model Number: BG 35-63

Range of Power: 45-100W

Range of Voltage:12-48VDC

Range of Rated Speed: 45-120rpm

Range of Rated Torque: 2-6N.m

Lifespan: 800Hours

Model Number: BG 86BL01

Range of Power: 300-800W

Range of Voltage:24-310VDC

Range of Rated Speed: 1500-6000rpm

Range of Rated Torque: 0.65-2.5N.m

Lifespan: 5000Hours

Model Number: BG 36-63

Range of Power: 52-125W

Range of Voltage:12-110VDC

Range of Rated Speed: 45-120rpm

Range of Rated Torque: 2-6N.m

Lifespan: 1000Hours

Model Number: BG 63ZYT-30k

Range of Power: 52-125W

Range of Voltage:12-110VDC

Range of Rated Speed: 1500-5000rpm

Range of Rated Torque: 0.15-0.4N.m

Lifespan: 1000Hours

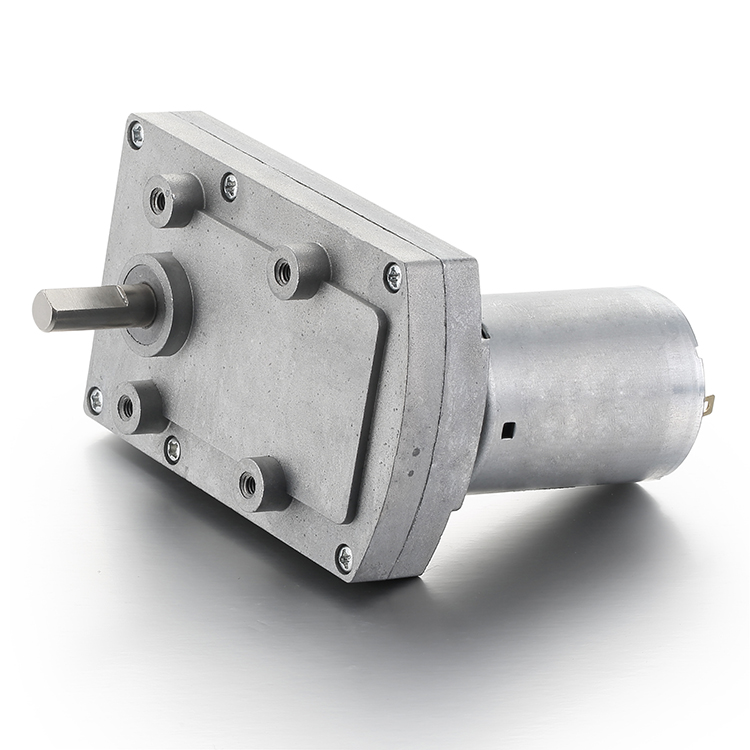

Model Number: BG 103ZYT94

Range of Power: 150-350W

Range of Voltage:12-48VDC

Range of Rated Speed:330-365 rpm

Range of Rated Torque: 4.5-5N.m

Lifespan: 1000Hours

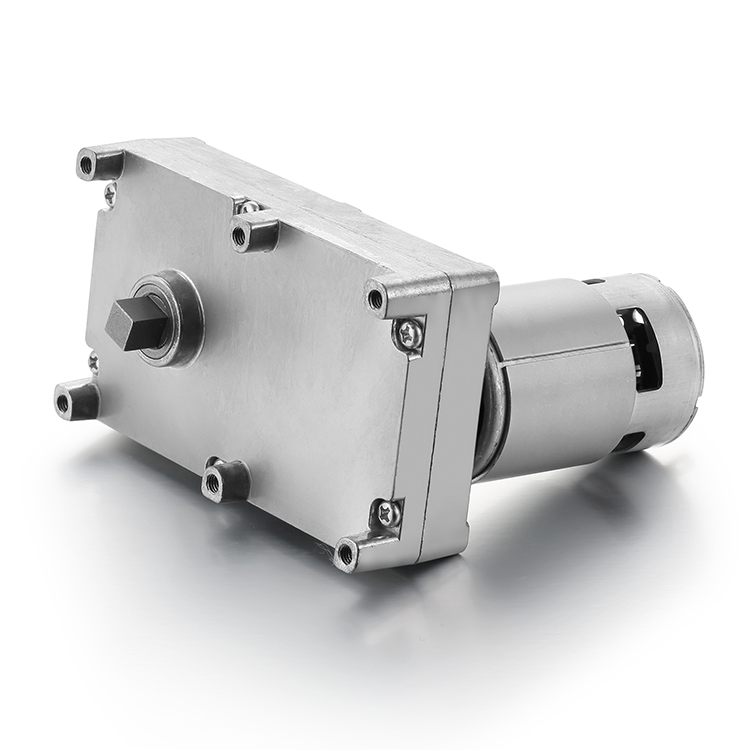

Model Number: BG 90ZYT196

Range of Power: 40-250W

Range of Voltage:12-220VDC

Range of Rated Speed: 17-400rpm

Range of Rated Torque: 3.6-60N.m

Lifespan: 1000Hours

Model Number: BG 90ZYT

Range of Power: 175-230W

Range of Voltage:24-48VDC

Range of Rated Speed: 1500rpm

Range of Rated Torque: 3.34-4.39N.m

Lifespan: 5000Hours

Model Number: BG 555

Range of Power: 3-13.5W

Range of Voltage:12-24VDC

Range of Rated Speed: 4-125rpm

Range of Rated Torque: 0.7-5N.m

Lifespan: 1000Hours

Model Number: BG 545

Range of Power: 3-9W

Range of Voltage:12-24VDC

Range of Rated Speed: 2-625rpm

Range of Rated Torque: 0.1-3N.m

Lifespan: 1000Hours

Model Number: BG 555

Range of Power: 3-13.5W

Range of Voltage:12-24VDC

Range of Rated Speed: 4-125rpm

Range of Rated Torque: 0.7-5N.m

Lifespan: 1000Hours

Model Number: BG 45ZYT

Range of Power: 12-50W

Range of Voltage:12-48VDC

Range of Rated Speed: 3-92rpm

Range of Rated Torque: 0.5-5N.m

Lifespan: 1000Hours

Model Number: BG 45ZYT76

Range of Power: 12-50W

Range of Voltage:12-48VDC

Range of Rated Speed: 3-92rpm

Range of Rated Torque: 0.5-5N.m

Lifespan: 1000Hours

Model Number: BG 545

Range of Power: 3-9W

Range of Voltage:12-24VDC

Range of Rated Speed: 2-625rpm

Range of Rated Torque: 0.1-3N.m

Lifespan: 1000Hours

Model Number: BG 50ZYT94

Range of Power: 30-80W

Range of Voltage:12-110VDC

Range of Rated Speed: 22-40rpm

Range of Rated Torque: 5-10N.m

Lifespan: 1000Hours

Model Number: BG 38

Range of Power: 1-3.6W

Range of Voltage:6-24VDC

Range of Rated Speed: 2-625rpm

Range of Rated Torque: 0.04-3N.m

Lifespan: 1000Hours

A worm gear motor is a reduction device that combines a worm and a worm wheel, and is usually used to convert the high-speed rotation of a motor into a low-speed, high-torque output. It is widely used in equipment that requires precise control of speed and torque, such as automated machinery, robots, transmission systems, etc.

The structure of worm gear motor is:

1. Worm: The worm is a spiral gear, usually made of high-strength material, responsible for transmitting the rotational motion of the motor to the worm wheel.

2. Worm wheel: The worm wheel is a disc-shaped gear with a helical tooth design that can mesh with the worm, receive the power of the worm and achieve deceleration.

3. Motor: The motor is the power source of the entire device, usually a DC motor or an AC motor.

4. Housing: Protects internal components and provides structural support.

5. Bearing: Supports the motor shaft and worm shaft to reduce friction and wear.

Self-locking function:The worm gear motor has a self-locking function, which can prevent reverse movement, and is suitable for lifting and safety braking and other occasions that need to prevent reverse movement.

Compact structure:The worm gear motor provides a large reduction ratio while being relatively small in size and compact in structure

Low vibration and noise:Due to the large gear contact surface, the vibration and noise of worm gear motors are low.

Smooth transmission:The meshing mode of the worm gear ensures the stability of the transmission, which is suitable for occasions that require stable transmission.

In addition, BG also provides customized solutions, including power, torque, size, appearance, etc., please refer to customized solution for specific webpages

Automation equipment: widely used in industrial automation systems such as conveyors, assembly lines and packaging equipment, providing precise speed control and high torque output.

Robotics: used in robot joints and drive systems to support flexible movement and high-precision positioning.

Electric doors and windows: used for the switch control of automatic doors and windows, providing stable power and safety.

Lifting equipment: In elevators, freight elevators and lifting platforms, worm gear motors provide the required torque and stability.

Household appliances: such as washing machines, refrigerators and other electric equipment, as a drive component to ensure efficient operation.

Agricultural machinery: used in automated agricultural equipment, such as seeders and irrigation systems, to improve work efficiency.

Medical equipment: used in drive systems in medical devices, such as electric beds and medical transport equipment, to provide safe and reliable performance.

Wind turbines: used to adjust the drive angle of the fan to ensure optimal power generation efficiency.

Transportation: in electric vehicles and rail transit systems, it provides power transmission and speed regulation.

Robotic arms: used for precision control of robotic arms to achieve complex control tasks.

BG worm gear motors are suitable for a variety of industries and application scenarios with their high efficiency, low noise and self-locking characteristics to meet the needs of different customers.

1. Load control: ensure that the motor load is within the rated range. Overload may cause the motor to overheat or damage.

2. Lubrication and maintenance: regularly check and replenish lubricating oil to reduce friction and wear and extend the service life of the motor.

3. Installation angle: Follow the manufacturer's installation requirements, avoid excessive tilt, and ensure the correct alignment of the motor and reducer.

4. Power supply stability: Ensure that the power supply voltage and frequency are stable to avoid voltage fluctuations affecting the operation of the motor.

5. Heat dissipation design: Provide sufficient heat dissipation space to avoid overheating of the motor, especially under high load conditions.

6. Protective measures: Ensure that the housing of the motor and reducer is intact to prevent dust, moisture, etc. from entering and affecting the performance of the motor.

7. Regular inspection: Regularly check the various components of the motor and reducer, including bearings, gears and cables, to detect and deal with potential problems in a timely manner.

8. Starting method: Use a suitable starting method to avoid direct starting with load to prevent current shock from damaging the motor.

9. Vibration monitoring: Monitor the vibration of the motor during operation. Abnormal vibration may indicate internal faults or wear.

10. Safe operation: Follow relevant safety operating procedures to prevent accidents caused by misoperation.

Following these precautions can improve the performance and reliability of the worm gear reducer motor and ensure its long-term stable operation.

BG Motor's unrivalled production advantages

1. As the original motor manufacturer, it directly connects with customers and there is no problem of intermediary traders.

2. It can provide free customized solutions, have a professional team of technical personnel, and do its best to solve practical problems for customers and gain customer trust.

3. Adopt green and environmentally friendly materials, actively assume the sense of social responsibility of enterprises, and while pursuing industrial development and progress, actively protect the natural ecological environment, not only save energy and reduce emissions, but also minimize noise.

4. It has a super-large production plant of 12,000 square meters and five automated production lines, which can be delivered and arrived as soon as possible.

5. Since its establishment in 1994, BG Motor has more than 30 years of production experience. Over the years, we have actively overcome various problems and obstacles and resolutely stand together with our customers! Resolutely not retreat! Resolutely assume the responsibilities of the company! You can contact us at any time and place, and we always serve you sincerely.

6. The gear reduction motors we produce have been fully recognized by the market and are widely used in high torque and high precision scenarios, such as robots, AGV cars, lifting equipment, home equipment, etc.

Archimedes once said: Give me a fulcrum and I will lift the entire earth.Then, I want to say - give BG Motor a chance, and you will have the most perfect product!