What is a brushed DC motor:

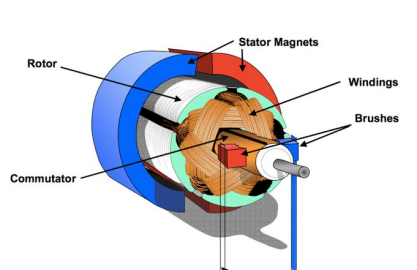

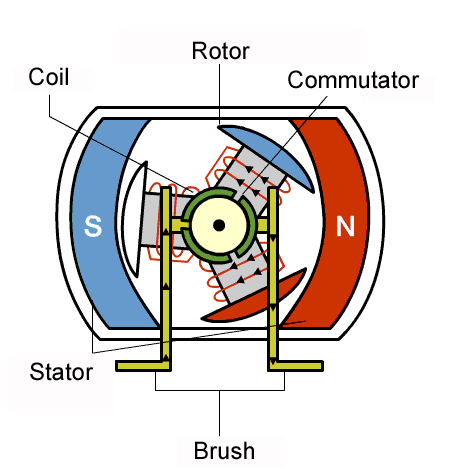

A brushed motor is a DC motor with fixed main poles, brushes on the stator, armature windings and commutator on the rotor. The electrical energy from the DC power supply enters the armature winding through the brushes and commutator to generate armature current. The magnetic field generated by the armature current interacts with the main magnetic field to generate electromagnetic torque, which makes the motor rotate and drives the motor to rotate.

The brush motor has a simple mechanism, easy to produce and process, easy to maintain, and easy to control; the DC motor also has the performance of fast response speed, large starting torque, and can provide rated torque from zero speed to rated speed.

The working principle of a brushed DC motor

There are magnets in the fixed part of the brushed DC motor, which is called the main pole here; there are brushes in the fixed part. The rotating part has a toroidal core and a winding wound on the toroidal core.

A pair of DC-excited stationary main magnetic poles N and S are installed on the fixed part (stator) of the two-pole brushed DC motor, and an armature core is installed on the rotating part (rotor). There is an air gap between the stator and the rotor. An armature coil composed of two conductors A and X is placed on the armature core. The head and end of the coil are respectively connected to two arc-shaped copper plates, which are called commutating plates. The commutator segments are insulated from each other, and the whole composed of commutator segments is called a commutator. The commutator is fixed on the rotating shaft, and the commutator segments and the rotating shaft are insulated from each other. A pair of fixed brushes B1 and B2 are placed on the commutator. When the armature rotates, the armature coil is connected to the external circuit through the commutator and the brush.

Types of brushed DC motors

① Motor with brushed disk winding. The brushed disk winding motor is bonded with rare earth materials on a cylinder body, and the disk winding made of enameled copper wire is placed in the cylinder body to form a rotor. The motor phase is adjusted by mechanical inverter. The mechanical inverter adjusts the voltage phase by friction between a fixed carbon brush and a rotating copper commutation surface. The brushes of this kind of motor have been worn out during use, and the service life of the motor is difficult to exceed 2000h. At the same time, due to the high speed of the motor, a two-stage gear reduction must be adopted. This brings about two problems. One is that the noise is large, and the other is the efficiency loss. The rated efficiency of the motor after deceleration can often only reach 68%. ~72%. The capacity of the battery used in electric bicycles is limited, generally 36V/12Ah. If the motor efficiency is not high, it will increase the power consumption and affect the continued mileage.

②Motor with brush printing winding. The brush printed winding motor uses printed copper foil as the winding, and the weight of the motor is reduced. Since this motor is all produced on an automatic production line, the process is reliably guaranteed, so that the life of the motor is increased to 3000h, the noise is greatly reduced, and the efficiency is increased to 72% to 76%. But this kind of motor has "buzzing" high-frequency noise, and the efficiency is still not ideal after gear reduction. The use of the brushed inverter makes the motor's lifespan unable to be improved.

③ Brushed winding motor. This kind of motor presses the wound copper wire into a new type of winding, and its efficiency can be increased to 74% to 78%. This kind of motor is still adopted by many electric bicycle manufacturers, but its efficiency, noise and life defects are still problems that must be improved.

The hub-type gear-driven brushed DC motor is composed of a disk-shaped armature brushed motor and a gear reduction and transmission system. The disk armature is a rotor that rotates at a high speed. The structure of the wheel-type geared brushed DC motor, the torque of the motor is transmitted to the first-stage gear through the shaft, and the hub shell is driven to rotate through the gear reduction.

The disk-shaped armature of the brushed geared hub motor is thin, small in size, light in weight, and easy to install. After the windings are prepared, use resin and glass fiber to put them into the mold for hot pressing. During operation, due to

the friction between the brush and the commutator, and the gear meshing and decelerating, the running sound of the brush motor is louder than that of the brushless motor. In order to adapt to the wheel hub structure, the brush motor is designed as a low-speed motor with an armature placed outside as a rotor, and a magnet placed inside the motor as a stator. Multiple pieces of magnets are equipped with multiple windings, and a low-speed motor with a design speed of about 180r/min. Shown is the armature winding that has not been pressure-shaped in the outer rotor of the motor. Inside the winding, there are commutating segments neatly arranged in a plane ring. Shown is a stator with 10 magnets arranged at intervals in the outer rotor. Two holes are opened on the middle hub plate. The brush holder of the brush is set on the back side of the hole, and the brush with the wire is The spring pops out of the brush holder.

The stator shaft end of the brush motor is covered with a nut, whose function is to prevent the thread on the shaft from being damaged during processing. Arrange the brush and put it into the brush holder, and then send this end into the hole shown in Figure 2-3(a), the brush can contact the commutator plane, and press the commutator with the elastic force of the spring. , And the magnetic steel just enters the outer rotor winding, leaving only a small annular air gap. The larger the diameter of this annular air gap, the greater the torque produced by the motor.

Due to the improvement in the design of the brushed motor, there is no need for gear reduction, which can achieve low noise and low cost. Many low-priced electric bicycles widely use this type of motor. However, this kind of motor has small torque, small load, poor climbing ability, and consumes a lot of electricity during use. Mechanical brush inverters are still used. The problem of motor life has not been solved. Therefore, medium and high-end electric bicycles are not used. This kind of motor.

working principle

The basic components of all BDC motors are the same: stator, brushes and commutator. Each component will be described in more detail later.

stator

The stator generates a fixed magnetic field around the rotor. This magnetic field can be generated by permanent magnets or electromagnetic windings. The type of BDC motor is divided by the structure of the stator or the way the electromagnetic winding is connected to the power supply (for different types of BDC motors, please refer to the types of stepper motors).

Rotor

The rotor (also called the armature) consists of one or more windings. When these windings are excited, a magnetic field is generated. The magnetic poles of the rotor magnetic field will attract the opposite magnetic poles of the stator magnetic field, thereby causing the stator to rotate. During the rotation of the motor, the windings are continuously excited in a different sequence, so the magnetic poles produced by the rotor will never overlap with the magnetic poles produced by the stator. This conversion of the magnetic field in the rotor winding is called commutation.

Brushes and commutator

Unlike other motor types (ie, brushless DC motors and AC induction motors), BDC motors do not require a controller to switch the direction of the current in the electrode windings, but mechanically complete the commutation of the BDC motor windings. A split copper sleeve is installed on the shaft of the BDC motor, which is called a commutator. As the motor rotates, the carbon brushes slide along the commutator and contact different segments of the commutator. These segments are connected to different rotor windings, so when power is applied through the brushes of the motor, a dynamic magnetic field is generated inside the motor. It is important to note that the brush and the commutator are the most easily lost parts of the BDC motor due to relative sliding between the two.

Permanent magnets

Permanent Magnet Brushed DC (PMDC) motors are the most common BDC motors in the world. This type of motor uses permanent magnets to generate the stator magnetic field. PMDC motors are commonly used in applications including fractional horsepower motors because permanent magnets are more cost-effective than winding stators. The disadvantage of PMDC motors is that the magnetic properties of permanent magnets will gradually decline over time. Some PMDC motors also have windings on the permanent magnets to prevent magnetic loss. The linearity of the PMDC motor performance curve (voltage vs. speed curve) is very good. There is a linear relationship between current and torque. Since the stator magnetic field is constant, this type of motor responds very quickly to voltage changes.

Simultaneously

The excitation coil of Shunt-wound Brushed DC (SHWDC) motor is connected in parallel with the armature. The current in the excitation coil and the current in the armature are independent of each other. Therefore, this type of motor has excellent speed control capabilities. SHWDC motors are usually used in applications that require five or more horsepower. In SHWDC motors, there is no magnetic loss problem, so they are generally more reliable than PMDC motors.

Cross-excitation

The excitation coil of the Series-wound Brushed DC (SWDC) motor is connected in series with the armature. Since the current in both the stator and armature increases with increasing load, this type of motor is ideal for high-torque applications. The disadvantage of the SWDC motor is that it cannot control the speed precisely like PMDC and SHWDC motors.

Re-excitation

Compound Wound (CWDC) motors are a combination of parallel and series motors. CWDC motors can generate two kinds of magnetic fields: series excitation and parallel excitation. CWDC motor combines the performance of SWDC and SHWDC motor, it has a larger torque than SHWDC motor, and can provide better speed control than SWDC motor.

Basic drive circuit

The drive circuit is used in applications that use a certain type of controller and require speed control. The purpose of the drive circuit is to provide a method for the controller to change the winding current in the BDC motor. The drive circuit allows the controller to pulse-width modulate the supply voltage of the BDC motor. In terms of power consumption, this speed control method is much more efficient than the traditional analog control method in changing the speed of the BDC motor. Traditional analog control requires an additional rheostat in series with the motor windings, which reduces efficiency. There are many ways to drive a BDC motor. Some applications only require the motor to run in one direction. The former adopts low-end drive, and the latter adopts high-end drive. The advantage of using low-side drivers is that FET drivers are not necessary.

The purpose of the FET driver is:

1. Convert the TTL signal driving the MOSFET to the level of the supply voltage.

2. Provide enough current to drive the MOSFET

3. Provides level conversion in half-bridge applications.

For the vast majority of PIC® microcontroller applications, the second point is usually not applicable, because the I/O pins of the PIC microcontroller can provide a current of 20 mA.

Note that in each circuit, there is a diode across both ends of the motor to prevent Back Electromagnetic Flux (BEMF) voltage from damaging the MOSFET. BEMF is generated during the rotation of the motor. When the MOSFET is turned off, the windings of the motor are still energized and a reverse current will be generated. D1 must have a suitable rating to be able to consume this current.

The bidirectional control of a BDC motor requires a circuit called an H bridge. The H-bridge gets its name from the appearance of its schematic diagram, which can make the current in the motor windings move in two directions. To understand this, the H bridge must be divided into two parts, or two half bridges. Q1 and Q2 form a half bridge, and Q3 and Q4 form another half bridge. Each half-bridge can control the turn-on and turn-off of one end of the BDC motor so that its potential is the supply voltage or ground potential. For example, when Q1 is turned on and Q2 is turned off, the left end of the motor will be at the potential of the supply voltage. Turning on Q4 and keeping Q3 off will ground the opposite end of the motor. The IFWD marked with an arrow shows the direction of current flow in this configuration.

Note that there is a diode (D1-D4) across each MOSFET. These diodes protect the MOSFET from the current spikes generated by the BEMF when the MOSFET is turned off. These diodes are only needed when the diodes inside the MOSFET are not enough to consume BEMF current. Capacitors (C1-C4) are optional. The value of these capacitors is usually no greater than 10pF, and they are used to reduce the RF radiation due to the buckling of the commutator.

In the forward and backward modes, one end of the bridge is at ground potential and the other end is at VSUPPLY. The IFWD and IRVS arrows depict the circuit path of the forward and backward operating modes, respectively. In coast mode, the terminals of the motor windings remain suspended, and the motor coasts by inertia until it stops. Brake mode is used to quickly stop the BDC motor. In brake mode, the terminal of the motor is grounded. When the motor rotates, it acts as a generator. Short-circuiting the leads of the motor is equivalent to an infinite load on the motor, which can quickly stop the motor. The IBRK arrow depicts this. When designing an H-bridge circuit, a very important matter must be considered. When the input of the circuit is unpredictable (such as during the startup of the microcontroller), all MOSFETs must be biased to the off state. This will ensure that the MOSFETs on each half-bridge of the H-bridge will never be turned on at the same time. Turning on the MOSFETs on the same half-bridge at the same time will cause a short circuit of the power supply, which will eventually damage the MOSFETs and render the circuit unable to work. The pull-down resistor on the input of each MOSFET driver will achieve this function.

speed control

The speed of a BDC motor is proportional to the voltage applied to the motor. When using digital control technology, pulse width modulation (PWM) signals are used to generate the average voltage. The winding of the motor acts as a low-pass filter, so a PWM signal with sufficient frequency will generate a stable current in the winding of the motor. The relationship between average voltage, supply voltage and duty cycle is given by the following formula:

Formula 1: VAVERAGE= D ×VSUPPLY

There is a proportional relationship between speed and duty cycle. For example, if a rated BDC motor rotates at 15000 RPM at 12V, when a signal with a 50% duty cycle is applied to the motor, the motor will (ideally) rotate at 7500 RPM. The frequency of the PWM signal is the focus of consideration. If the frequency is too low, the motor speed will be too low, the noise will be large, and the response to the duty cycle changes will be too slow.

If the frequency is too high, the efficiency of the system will be reduced due to the switching loss of the switching device. The rule of thumb is to modulate the frequency of the input signal in the range of 4 kHz to 20 kHz. This range is high enough, the noise of the motor can be attenuated, and the switching loss in the MOSFET (or BJT) can also be ignored at this time. Generally speaking, it is a good way to find a satisfactory PWM frequency by experiment for a given motor. How to use PIC microcontroller to generate PWM signal to control the speed of BDC motor? One method is to alternately flip the output pin level by writing special assembly or C code (1). Another method is to choose a PIC microcontroller with a hardware PWM module. The modules provided by Microchip with this function are CCP and ECCP modules. Many PIC microcontrollers have CCP and ECCP modules. Please refer to the product selection guide for devices with these functional modules.

Note 1:Microchip's application note AN847 gives an assembly code example for pulse width modulation of I/O pins using firmware.

The CCP module (abbreviation for Capture Compare and PWM (Capture Compare and PWM)) can output a 10-bit PWM signal on an I/O pin. 10-bit resolution means that the module can achieve 210 (ie 1024) possible duty cycle values in the range of 0% to 100%. The advantage of using this module is that it can autonomously generate PWM signals on the I/O pins, which frees the processor and gives it time to complete other tasks. The CCP module only requires the developer to configure the parameters of the module. The configuration module includes setting frequency and duty cycle registers. The ECCP module (short for Enhanced Capture Compare and PWM (Enhanced Capture Compare and PWM)) not only provides all the functions of the CCP module, but can also drive a full-bridge or half-bridge circuit. The ECCP module also has an automatic shutdown function and a programmable dead time delay.

Note2:Microchip's application note AN893 gives a detailed description of configuring the ECCP module to drive the BDC motor. This application note also contains firmware and driver circuit examples.

Feedback mechanism

Although the speed of a BDC motor is generally proportional to the duty cycle, there is no perfect motor. Heat, commutator wear and load will affect the speed of the motor. It is a good idea to introduce some kind of feedback wit in a system that requires precise control of speed. Speed control can be achieved in two ways. The first way is to use some type of speed sensor. The second way is to use the BEMF voltage generated by the motor.

Sensor feedback

There are a variety of sensors that can be used for speed feedback. The most common are optical encoders and Hall effect sensors. The optical encoder consists of multiple components. Install a sheave on the shaft at the non-drive end of the motor. An infrared LED provides a light source on one side of the wheel, and a phototransistor detects light on the other side of the wheel. Light passing through the slot in the wheel turns on the phototransistor. When the rotating shaft rotates, the phototransistor will turn on and off according to whether the light passes through the wheel groove or not. The frequency of transistor on and off characterizes the speed of the motor. In applications where the motor is shifted, an optical encoder will also be used to feedback the motor position.

Hall effect sensors are also used to provide speed feedback. Similar to an optical encoder, a Hall-effect sensor requires a rotating element connected to the motor and a stationary element. The rotating element is a wheel with one or more magnets mounted on its outer edge. The stationary sensor detects the passing magnet and generates TTL pulses.

Back Electromagnetic Flux (BEMF)

Another form of providing fast feedback for BDC motors is BEMF voltage measurement. The BEMF voltage is proportional to the speed. Figure 11 shows where the BEMF voltage is measured in the bidirectional drive circuit. A voltage divider is used to reduce the BEMF voltage to the 0-5V range so that it can be read by the analog-to-digital converter. The BEMF voltage is measured between PWM pulses when one end of the motor is floating and the other end is grounded. In this case, the motor acts as a generator and produces a BEMF voltage proportional to the speed.

Due to differences in efficiency and materials, all BDC motors will behave slightly differently. Experiments are the best way to determine the BEMF voltage for a given motor speed. The reflective band on the motor shaft helps the digital tachometer to measure the motor's speed (in RPM). When reading the digital tachometer and measuring the BEMF voltage, the relationship between the motor speed and the BEMF voltage will be obtained.

Note: Microchip's application note AN893 provides firmware and circuit examples for reading BEMF voltage using PIC16F684.

Excitation method of DC motor

Different from the synchronous motor, because the stator and rotor of the DC motor, that is, the main magnetic pole and the armature flow through the DC current, the main magnetic pole excitation winding can be connected in parallel with the armature winding, or in series with the armature winding, or Separately powered by other DC power sources. According to the different ways of obtaining the excitation current of the main magnetic pole, they are called different excitation methods.

To sum up

The use and control of the brushed DC motor are very simple, so its design cycle is relatively short. PIC microcontrollers, especially microcontrollers with CCP or ECCP modules are ideal for driving BDC motors

BACK

BACK

Yesterday, the 138th China Import and Export Fair (Canton Fair) was grandly open…

In the golden autumn of October, the fruits are fragrant. On this beautiful mome…

Dear friends, the 138th Canton Fair will be held in Pazhou, Guangzhou on October…

At BG Motor, we firmly believe that the strength of a team can carry dreams furt…

New Breakthrough at Conifer (Silicon Valley Startup)What’s new?Conifer has devel…

The 2025 World Robot Conference (WRC), held in Beijing, brought together top min…