For friends who are new to the planetary reducer, they will certainly be very interested in the planetary reducer. How to improve the bearing capacity of the planetary reducer? Now let's follow BG motor to learn about it.

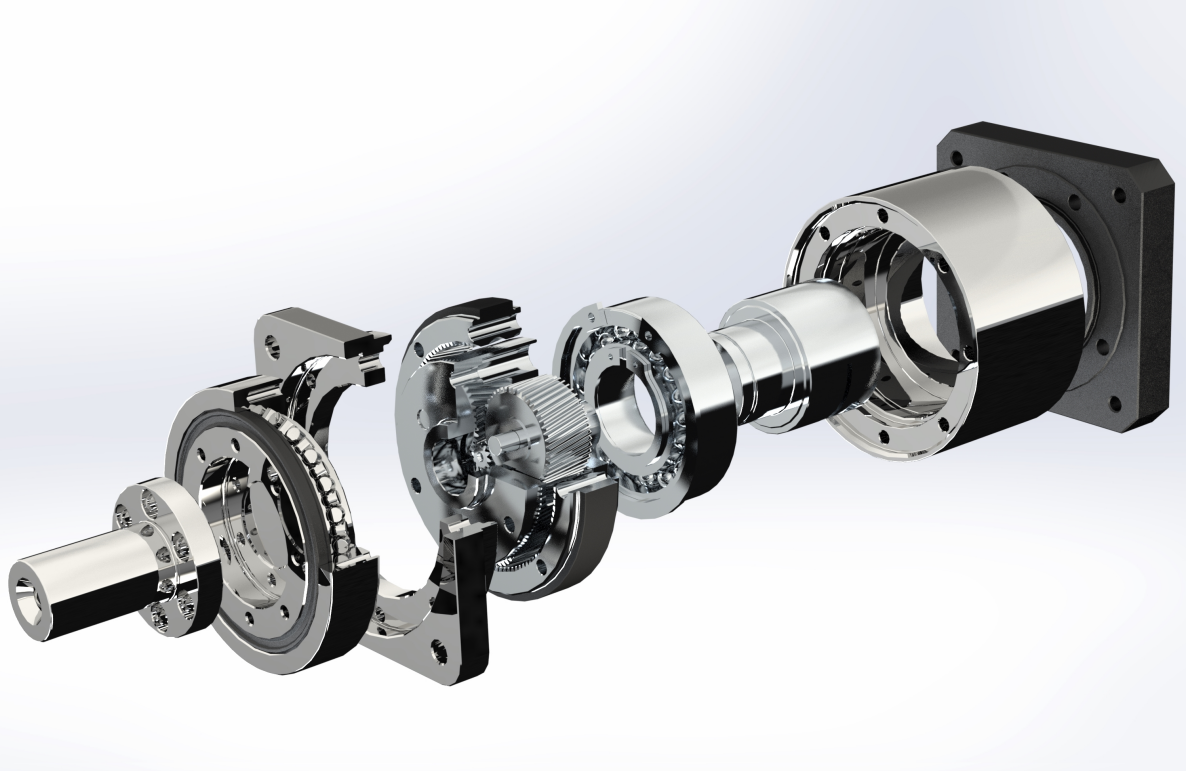

The planetary gearbox, i.e. the planetary reduction box, is also called the planetary gearbox. Its structure is a mechanism in which multiple planetary gears rotate around a sun gear. It is also a mechanism that reduces the transmission speed ratio and increases the motor torque in proportion.

Characteristics and Application

Features: Compared with a similar ordinary gearbox, it has stable transmission, large bearing capacity, small space, large transmission ratio, especially service life. If the gear is steel, the service life can reach 20000 hours, small volume, and beautiful appearance.

Application: the planetary gearbox is widely used. It was initially used with a motor. In addition to micro reduction motor, it is also used in sunshade industry, office automation, smart home, production automation, medical equipment, financial machinery, game console and other fields, such as automatic curtain, smart toilet, lifting system, cash counter, advertising lightbox and so on.

Planetary gearboxes on the market mainly have diameters of 16mm, 22mm and 28mm 32mm, 36mm, 42mm, 57mm, 60mm, 80mm, 86mm, 90mm, 110mm, matched with the motor, its function can achieve load torque: 1nm-200Nm, load output speed: 3-800rpm.

What are the ways to improve the bearing capacity of a planetary gearbox with the same diameter?

1. Increase the contact stress of the gear ring

The check strength of planetary reducer is usually to check the transmission contact stress of sun gear planetary gear, bending stress of sun gear planetary gear, and contact stress of planetary gear internal gear.

The contact stress of the ring gear usually fails first, so in order to increase the bearing capacity, we must first ensure the contact stress of the ring gear.

2. Gear modification

Tooth profile trimming, root trimming, and tooth end trimming are good methods to improve the transmission performance of heavy-duty gears, because for heavy-duty gears, generally, tooth end trimming can prevent tooth end overload caused by tooth alignment error.

3. Adjustment of displacement coefficient

The correct selection of displacement coefficient can increase the bearing capacity of gears by 20% to 30%.

4. Control gear accuracy and error

The tooth surface strength is not only related to the gear accuracy grade but also related to the value of base pitch error. If the base pitch error of the gear is large, the rolling pressure on the gear teeth is also large.

5. Select the material of gear

Forged Steel / cast steel / non-metallic material/alloy steel/nylon. The materials will be very different due to different purposes, and the selection of materials is very important.

6. Root reinforcement

The bending strength of gear has a great relationship with the surface condition of the tooth root, especially the decarburization layer and other defects on the surface of the tooth root of carburized and quenched gear, which is difficult to ensure the residual pressure and reduce the bending fatigue strength of tooth root. Therefore, tooth root strengthening measures are taken to improve the fatigue strength.

7. Increase tooth width

When the outer diameter requirements of planetary reducer remain unchanged, appropriately increasing the width of internal gear can effectively increase the bearing capacity of gear.

BACK

BACK

On May 5, the 137th Canton Fair officially concluded. This "Made in China f…

Focusing on the industrial trend of the 2025 Canton Fair, BG Motor continues to …

On April 16, 1963, Martin Luther King Jr. famously wrote in Birmingham Prison th…

The 137th Canton Fair in the spring of 2025 will officially kick off on April 15…

Historical trends in electric vehiclesThe development of electric vehicles (EVs)…

In February 2025, BG Motor ushered in the traditional Lantern Festival celebrati…