Two main types of brushless motors are introduced: inner rotor type motors and outer rotor type motors.

Brushless motors combine permanent magnets, windings, pole sensors, and drive circuitry to perform the functions of a motor. This motor is excellent in both speed regulation and energy saving. Compared to using inverters and firing angle control to control the speed of induction motors, these motors can be used in a wide speed range from low to high speed rotation. In addition, permanent magnets are used in the rotor, and since there is no need to induce current in the rotor like an induction motor, the BLDC motor is small in size, high in output power, and high in efficiency.

However, brushless DC motors have traditionally been expensive and have limited applications due to the need for permanent magnets, pole sensors, and dedicated drive circuits in the rotor.

In recent years, with the increase in the degree of integration of electronic components, the development of electronic equipment has reduced the cost and size of driving circuits. In addition, in order to cope with global warming, the requirements for energy saving are getting higher and higher, and brushless DC motors have been widely used in energy-saving appliances such as air conditioners, refrigerators, and washing machines, as well as drive motors and vehicles. Electric motors for electric and hybrid vehicles. Their compact size and high output power allow them to be used in a variety of applications,

Includes cooling fans for touchscreen panel computers, disk drive devices, and drones.

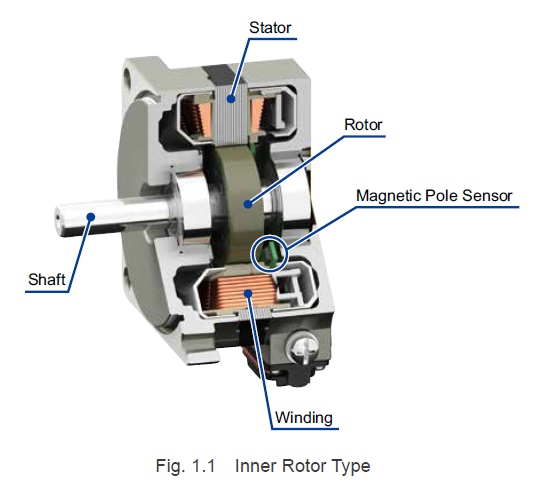

Brushless Motor------Inner Rotor Series

For the "inner rotor" type, the rotating part (aka rotor) is inside the stator, and the segmented permanent magnets are mounted on the outer surface of the rotor. It provides excellent acceleration and deceleration responsiveness due to small rotor diameter and low moment of inertia. In addition, since the stator is located close to the surface of the motor, the heat dissipation is good, and a compact motor with high output power can be realized.

This is a typical configuration for a brushless motor and is versatile. In my opinion, they save space or increase the efficiency of material handling applications such as pulleys driving conveyors and/or wheels driving AGVs.

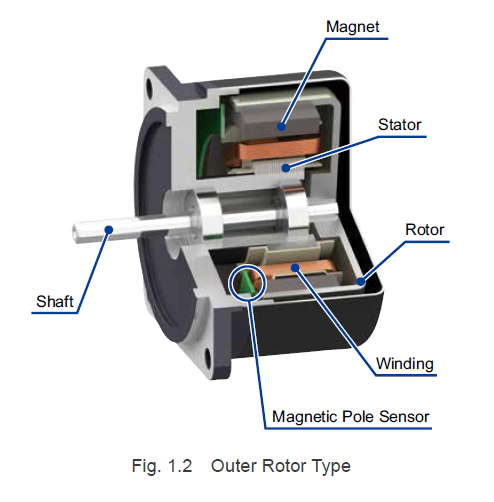

Brushless Motor------Outer Rotor Series

For the "outer rotor" type, the rotor is located outside the stator and the permanent magnets are located inside the rotor. Segmented permanent magnets are now mounted on the inner surface of the rotor. The position of the stator and permanent magnets is opposite to that of the inner rotor type. Due to the large moment of inertia, the cup-shaped rotor has poor acceleration and deceleration response and is not suitable for agile movement, but it can still provide excellent speed stability.

Due to the larger diameter of the rotor, more magnets can be mounted compared to the inner rotor type, and the number of magnetic poles is increased compared to the inner rotor type. This makes it possible to achieve high output power in a compact size.

The outer rotor type has a narrower range of applications. The greater inertia of the rotor makes it more difficult to start and stop quickly. Poor heat radiation characteristics limit operating time. However, if the motor is designed with thermal ventilation, radiation or cooling in mind, the application can extend to cooling fans and drones, etc.

BACK

BACK

Yesterday, the 138th China Import and Export Fair (Canton Fair) was grandly open…

In the golden autumn of October, the fruits are fragrant. On this beautiful mome…

Dear friends, the 138th Canton Fair will be held in Pazhou, Guangzhou on October…

At BG Motor, we firmly believe that the strength of a team can carry dreams furt…

New Breakthrough at Conifer (Silicon Valley Startup)What’s new?Conifer has devel…

The 2025 World Robot Conference (WRC), held in Beijing, brought together top min…