The influence of the rare earth neodymium magnet manufacturing process on the motor?

Rare earth neodymium magnets (NdFeB), commonly known as neodymium magnets, are currently the strongest permanent magnets. They are mainly made of alloys of neodymium (Nd), iron (Fe) and boron (B). , to wind turbines and many other industries. The magnetism of a magnet is the sum of the orbital angular momentum magnetic moment and the intrinsic magnetic moment of all electrons in the magnet, of which the intrinsic magnetic moment (mainly the electron spin magnetic moment) is the most important contributor. Neodymium magnets are powerful but less conspicuous magnets that have more magnetism in their smaller size compared to other magnets, making them a versatile option especially for small spaces , but can meet the needs of high magnetic products.

Manufacturing Process of Neodymium Magnets (NdFeB)

Neodymium rare earth magnet alloys are made from an alloy mainly composed of neodymium (Nd), iron (Fe) and boron (B), with the addition of additional elements, depending on the grade of magnets produced and the temperature required for operation Typically consisting of aluminum (AL), niobium (Nb), and dysprosium (Dy), after mixing, the elements are placed in a vacuum furnace where they are heated and alloyed through a vacuum induction melting process that uses electrical current to melt the elements while keeping them contamination-free thing.

melting and grinding

Once all the ingredients are obtained, they are usually melted with an electric current to form lumps or bars. These alloy ingots are then ground or ground into powder and mixed in preparation for pressing by means of a jet mill, which allows the creation of particles of a specific size. The composition and mixture of the alloy determines the strength, grade and other properties of the magnet, and for the production of neodymium magnets, the abrasive particles are typically around 3 microns in size.

Press and magnetize

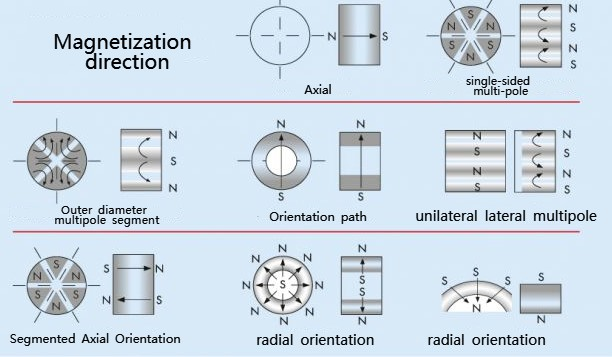

After the grinding process, the particles are pressed together. The method used varies depending on the magnet grade produced and the manufacturer. The three main pressing methods are axial, transverse and isostatic pressing. During pressing, an external magnetic field is applied to align and set the magnetic domains of the particles in one direction, called the magnetization direction. After the pressing process is complete, the material is demagnetized prior to sintering, which involves heating the material in an oxygen-free environment to extremely high temperatures but below the material's melting point. After pressing by applying a magnetic field to give the preferred direction of magnetization, magnet manufacturers end up with a block that is sintered to give it sharper magnetism.

sintering

After pressing, the magnets are not yet very strong, and sintering helps lock the magnetic particles in place by applying heat, carefully heating the alloy mixture to a temperature high enough to stick but low enough to avoid liquefaction. Sintering fuses the already pressed particles together to form a solid mass, and a complete magnet is rapidly cooled through a process called quenching, maximizing magnetic properties and minimizing the potential for alloy variant with poorer magnetic properties.

Machining

Sintering typically shrinks magnets, often requiring specific sizes and shapes for their respective applications, so a process called machining is used to define the shape and tolerances. After cooling, the magnets are machined into the desired shape using wire-cut electric discharge or diamond cutting tools, and cleaned and dried before electroplating to prevent corrosion.

Plating

Neodymium will corrode, so to prevent corrosion, there is a coating on the magnet. Most neodymium magnets are first plated with a layer of nickel, then plated with a layer of copper, and finally plated with a layer of nickel. It can also be used according to specific requirements. Other professional coatings and coatings.

magnetization

Now the magnets are almost ready, but they are not yet fully magnetic, in other words, they have been assigned a pole orientation, but the magnetic force has not been activated, and they will not exert their full magnetic power to attract or repel. To activate their magnetism, industrial magnetizers are often used. A magnet block is placed in it and exposed to a strong magnetic field, then the magnet is placed inside the electromagnetic coil and exposed to a magnetic field at least 3 times stronger than the magnet requires and magnetized to saturation for maximum magnetic output, which This is achieved by aligning the magnet and its magnetization with the magnetic field.

Magnetic pole direction

Pole Orientation The easiest way to identify a magnet's poles is to use a numeric pole identifier, or to use a magnet with an identified pole. A compass is enough to identify the pole orientation of a magnet. When using a compass to identify the poles of a magnet, it is important to remember that the poles are attracted to their opposite poles. The compass needle itself is a small magnetic rod, so there is a North Pole and one South Pole.

The alignment of the magnetic poles can be observed by using a magnetic viewing film, which reacts to the magnetic field lines of the magnet below it. The dark areas of the viewing film represent the pole faces and the light areas represent the gaps between the poles. By measuring the gap between the magnetic field lines, the pole spacing (frequency) can be determined, and the magnetic viewing membrane does not indicate whether the north pole is north or south. Magnetic observation films contain a colloidal solution of tiny nickel flakes suspended in a viscous oily substance. Nickel is ferromagnetic and the flakes react under the action of a magnetic field. When suspended in solution and simultaneously exposed to a magnetic field, they can rotate unhindered, aligning them along magnetic flux lines.

in conclusion

The performance of the magnet is also affected by the crystal structure. The structure of some crystals is conducive to the formation of relatively strong magnetic anisotropy. When designing a magnet, it is also necessary to consider how to optimize the crystal structure to obtain better performance. The process of making a neodymium magnet is a complex and interesting process, it is important to do it in a professional manner, and the way the magnet is formed affects how it functions. There are two methods of manufacturing neodymium magnets: bonded NdFeB and sintered NdFeB.

Bonded NdFeB magnets are actually formed by injection molding, while sintered NdFeB magnets are formed by evacuation and then heated at high temperature.

Because the bonded NdFeB magnets are injection-molded, they contain a binder, and the density is generally only 80% of the theoretical value. The sintered NdFeB magnet is heated at high temperature through a complex process, so in terms of magnetic properties, the bonded NdFeB magnet is attenuated by about 30% relative to the sintered NdFeB magnet.

Sintered NdFeB is an anisotropic magnet produced by powder sintering. Generally, only blanks can be produced after sintering, and then through machining (such as wire cutting, slicing, grinding, etc.), magnets of various shapes can be formed. Sintered NdFeB is a brittle and hard material that is difficult to process. It has large losses during processing, high cost, poor dimensional accuracy, and poor corrosion resistance. The surface needs electroplating. But the advantage is that the performance is higher, and it has reached more than 50M.

Most of the motors we produce are made of sintered NdFeB, all of which are guaranteed in terms of motor performance. If you are interested in our motors, please browse the products on our official website, we are ready to recommend for you at any time.

BACK

BACK

Yesterday, the 138th China Import and Export Fair (Canton Fair) was grandly open…

In the golden autumn of October, the fruits are fragrant. On this beautiful mome…

Dear friends, the 138th Canton Fair will be held in Pazhou, Guangzhou on October…

At BG Motor, we firmly believe that the strength of a team can carry dreams furt…

New Breakthrough at Conifer (Silicon Valley Startup)What’s new?Conifer has devel…

The 2025 World Robot Conference (WRC), held in Beijing, brought together top min…