1. The direction of the oil road

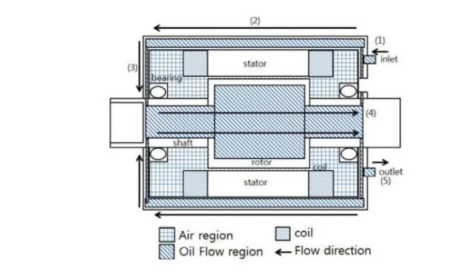

First of all, let's take a look at the overall solution of the motor oil cooling we are going to discuss. The direction of the oil circuit is shown in the following figure:

Compared with the traditional scheme, this scheme is special in that the cooling oil circuit of the rotor is added on the basis of the general stator water cooling scheme. The cooling oil flows into the casing from the front cover, forms an annular oil path in the stator iron core, collects into the rotor from the rear cover, and reaches the outlet of the front cover from the inside of the rotor.

2. Motor oil cooling structure

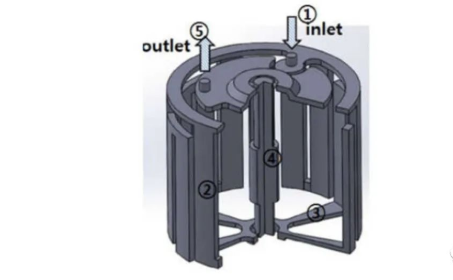

In order to realize the above oil circuit, the structure of the front and rear covers and the casing of the motor is shown in the following figure:

It is worth mentioning that the axial oil passage of the motor casing adopts multiple inlet and outlet methods, so that the flow resistance of the oil passage is relatively small.

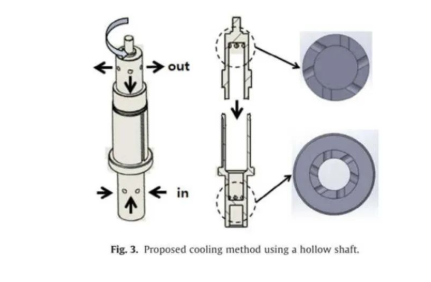

In addition, for the rotor, it adopts the form of two-stage processing and then welding, the rotor The structure is as follows:

3. Simulation iterative process

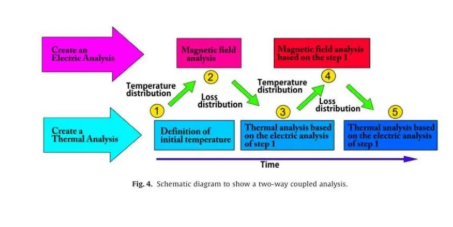

The basic process of simulation is shown in the following figure:

The simulation process is based on the bidirectional coupling analysis of the temperature field and the electromagnetic field. First, the initial temperature is given, and then the loss at this temperature is calculated through the electromagnetic simulation, and then the loss is transferred to the temperature field analysis. This is repeated iteratively until steady state. In order to shorten the simulation time, 2D digital model is used for electromagnetic field simulation, and 3D digital model is used for temperature field simulation. For the heat transfer coefficient of rotor and stator relative to the air gap, refer to the empirical value.

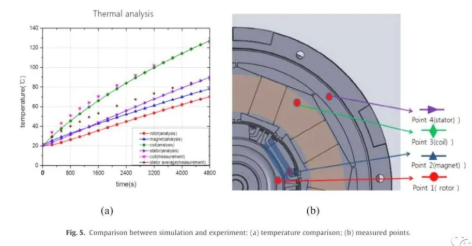

4.the actual measurement verification

The different positions and actual temperature values of the motor are measured and compared with the simulated values. Taking the working state of 2300rpm and 7.38Nm as an example, the simulation error can be obtained within 10%. The specific values are shown in the figure below:

5. Optimization of the motor

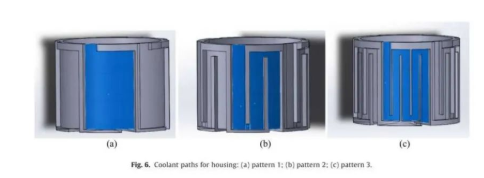

(1). Case cooling oil passage

The oil passages in three different forms are as follows:

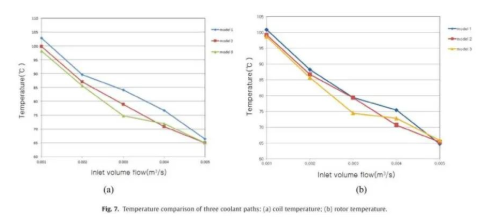

Analyze the stator and rotor temperatures of the three structures under the conditions of different flow rates as shown below:

It can be seen from the chart that we can determine the oil passage structure of the casing after comprehensive consideration according to the system flow and temperature requirements. It is obvious that from a to b, when the cooling oil flow is low, the cooling effect of the winding is significantly improved, while the cooling effect of c is not significantly improved compared to b; when the cooling oil flow is high, the cooling effect of c Neither the winding nor the rotor is as good as b, even if its structure is more complex. This shows that when we design the oil passage of the casing, we need to design in combination with the flow of cooling oil, so as to find an optimal cooling scheme that matches the flow and passage design.

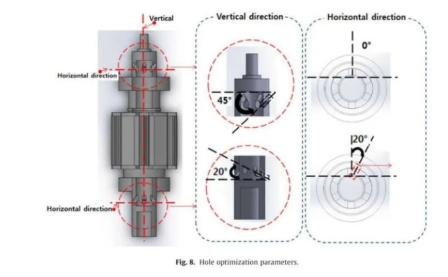

(2). Rotor inlet and outlet

The angle of the oil inlet and oil outlet of the rotor is an optional variable, and the variable can be set to the angle as shown in the figure below.

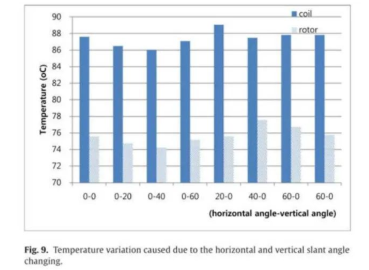

By simulating several sets of specific angle values, the results shown in the figure below can be obtained.

The comparison shows that the third group of combinations is the optimal solution.

6. Test method

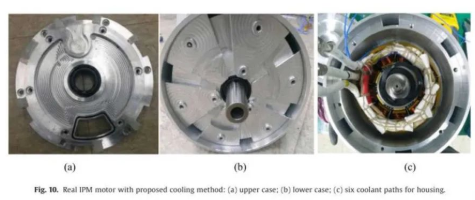

The actual prototype has six oil cooling channels on the stator casing. As shown below:

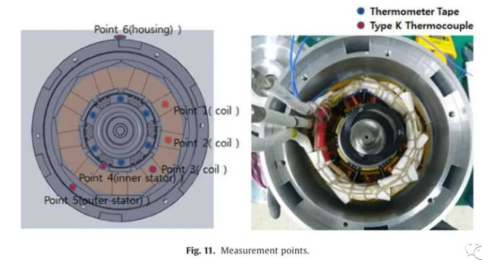

To measure the temperature of the stator and rotor, the thermistor is placed on the stator coil, iron core, and casing, which cannot be directly measured on the rotor, and is measured by label paper. The measurement points are as follows:

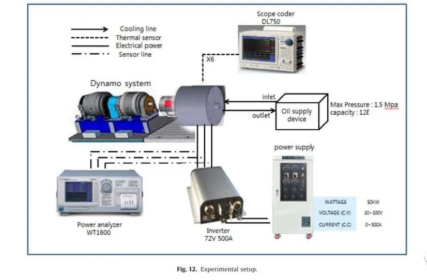

Test system:

7. Test results

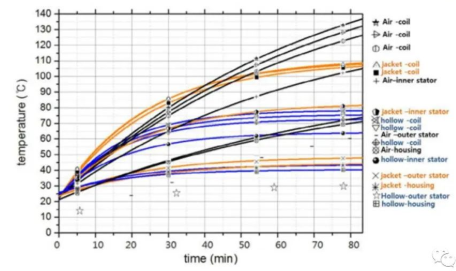

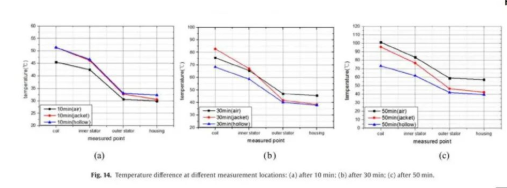

Three conditions: air cooling, single housing oil cooling and housing plus shaft oil cooling

result:

After 80 minutes of air cooling, the motor temperature is 130 ° C, and it has not reached equilibrium

After 80 minutes of oil cooling, the motor temperature reaches 110°C and reaches equilibrium

After 30 minutes of oil cooling of the housing and shaft, the motor temperature is 80°C, and the balance is reached.

In addition, compared from the time axis, the cooling effect of single-shell oil cooling and shell-shaft oil cooling is roughly the same before 10 minutes. After 30 minutes, the cooling effect of the two is significantly different, and the trend of this difference is expanding. .

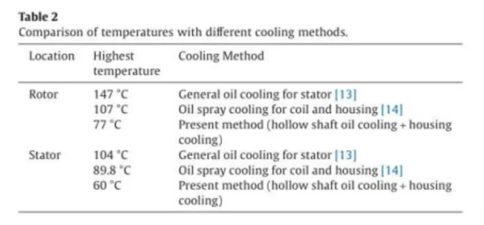

The cooling effect of this scheme is compared with the common single shell cooling and fuel injection scheme, as shown in the following table:

8. Summary

Compared with the traditional air cooling scheme, the coil temperature is reduced by 50%, and compared with the single-shell oil cooling scheme, the coil temperature is reduced by 38%, so it is an effective scheme to improve the cooling capacity of the motor.

BACK

BACK

Yesterday, the 138th China Import and Export Fair (Canton Fair) was grandly open…

In the golden autumn of October, the fruits are fragrant. On this beautiful mome…

Dear friends, the 138th Canton Fair will be held in Pazhou, Guangzhou on October…

At BG Motor, we firmly believe that the strength of a team can carry dreams furt…

New Breakthrough at Conifer (Silicon Valley Startup)What’s new?Conifer has devel…

The 2025 World Robot Conference (WRC), held in Beijing, brought together top min…