Most linear motion systems in various industries and industrial applications require moving parts such as bushings, also known as oil-impregnated and ball bearings. They have important features such as reduced part wear, longer life, lower noise and lower power consumption, and are used in machinery, speed applications, automotive projects, and even aerospace.

Because not every customer understands the difference between ball bearing types and oil-impregnated bearings. The following information will give you a detailed introduction

Bushing vs Ball Bearing: A Quick Overview

|

Bushings |

Ball Bearings |

|

More friction |

Deal with minor misalignments |

|

Not intended to take much lateral force |

Bearing design allows for easier management of heavy and high loads and axial loads and forces |

|

Common bushing materials are bronze, alloys, graphite, stainless steel, and similar heavy-duty metals |

Smoother motion than bushings |

|

Impregnated with oil for lubrication to become self-lubricating |

Built with tighter tolerances for a tighter fit |

|

More cost-effective than many linear ball bearings, roller ball bearings, rolling element bearings, and journal bearings. |

Available in various materials, which means you can purchase plastic bearings, steel bearings with corrosion resistance, and ceramic bearings. |

|

Quieter than ball bearings at low speeds and high speeds. |

Linear ball bearings can only be used on hardened shafts |

|

Can be used on hardened or non-hardened shafts |

The linear type of bearing must be used with hardened shafts like chrome-plated. |

|

Bushings, like drill bushings, generally require less maintenance than linear ball bearings |

You must lubricate the shaft periodically and perform maintenance to avoid contaminants |

|

They must overcome static high and low friction forces on moving parts |

Can lose their smooth motion, resulting in increased noise and jamming |

|

Wider tolerances that can negatively impact the fit on smooth rods |

Require more maintenance than bushings |

What are oil-impregnated bearings?

Oil-impregnated bearings, namely Porous Bearings, use metal powder as the main raw material. Oil-impregnated bearings are sintered bodies made by powder metallurgy, which are inherently porous and have pores that can be adjusted more freely during the manufacturing process. Technical advantages in quantity, size, shape and distribution

Features:

It has the characteristics of low cost, vibration absorption, low noise, and no need to add lubricating oil in a long working time. It is especially suitable for working environments that are not easy to lubricate or do not allow oil to be dirty. Porosity is an important parameter for oil-impregnated bearings. Oil-impregnated bearings that work at high speed and light load require a large amount of oil and high porosity; oil-impregnated bearings that work at low speeds and large loads require high strength and low porosity. This kind of bearing was invented in the early 20th century. Because of its low manufacturing cost and convenient use, it has been widely used and has become an indispensable part of the development of various industrial products such as automobiles, home appliances, audio equipment, office equipment, agricultural machinery, and precision machinery. A class of basic parts. Oil-impregnated bearings are divided into copper-based, iron-based, copper-iron-based, etc.

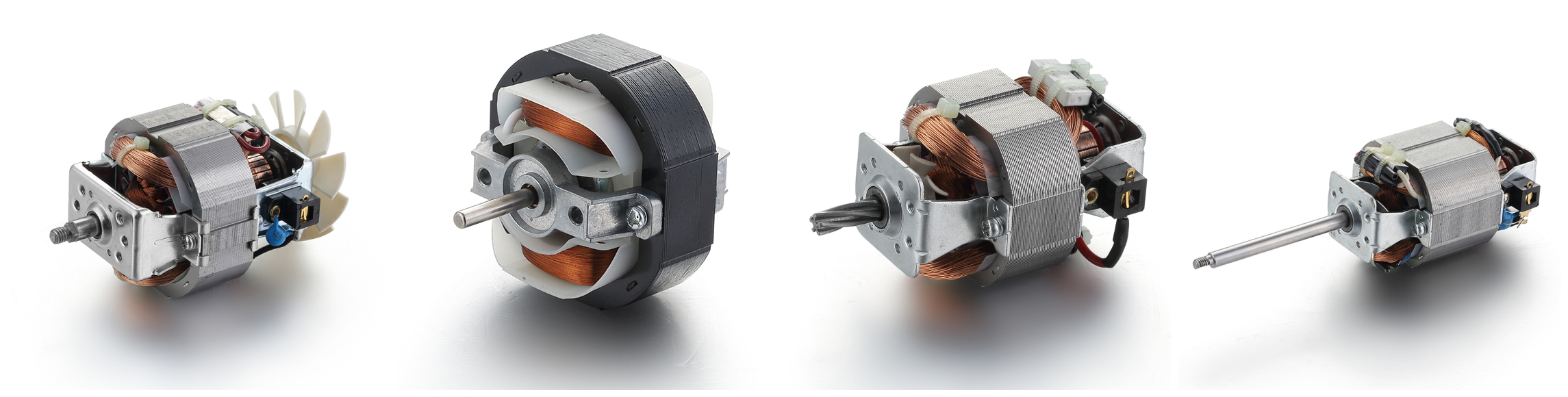

Common motor models are: BG AC6325, BG AC6335, BG AC5435, BG AC28, YJ58, etc.

Motor data:

Power Range: 10W-1200W

voltage Range: AC110-220V, 50/60Hz

Rated Speed Range: 4000-15000RPM

Size Range (diameter): 44MM-95MM

Shaft: Based on the drawing you offered, we can process the shaft into corresponding diameter, length and shape.

Front&back cover: We offer the professional moulding service with customers’ requirement and drawing.

The parts can be paired with universal motor: Planetary Gear Box/EMC/Overheat protector

What is a ball bearing?

Ball bearing is a kind of rolling bearing. The spherical alloy steel ball is installed between the inner steel ring and the outer steel ring to reduce the friction during the power transmission process and improve the transmission efficiency of mechanical power by rolling. Ball bearings cannot withstand large heavy loads and are more common in light industrial machinery. Ball bearings are also called ball bearings.

Ball bearings are generally used in low-load mechanical transmission equipment. Because the bearing area of the ball bearing is small, it is very easy to cause serious mechanical damage in the case of high-speed operation. Therefore, needle roller bearings are often used in heavy-load mechanical transmission to increase the bearing surface, improve the mechanical transmission efficiency, and reduce the mechanical damage.

The ball bearing changes the friction mode of the bearing and adopts rolling friction, which more effectively reduces the friction between the bearing surfaces, improves the service life of the fan bearing, and thus prolongs the service life of the radiator. The disadvantage is that the process is more complicated, the cost is increased, and it also brings higher working noise.

![]()

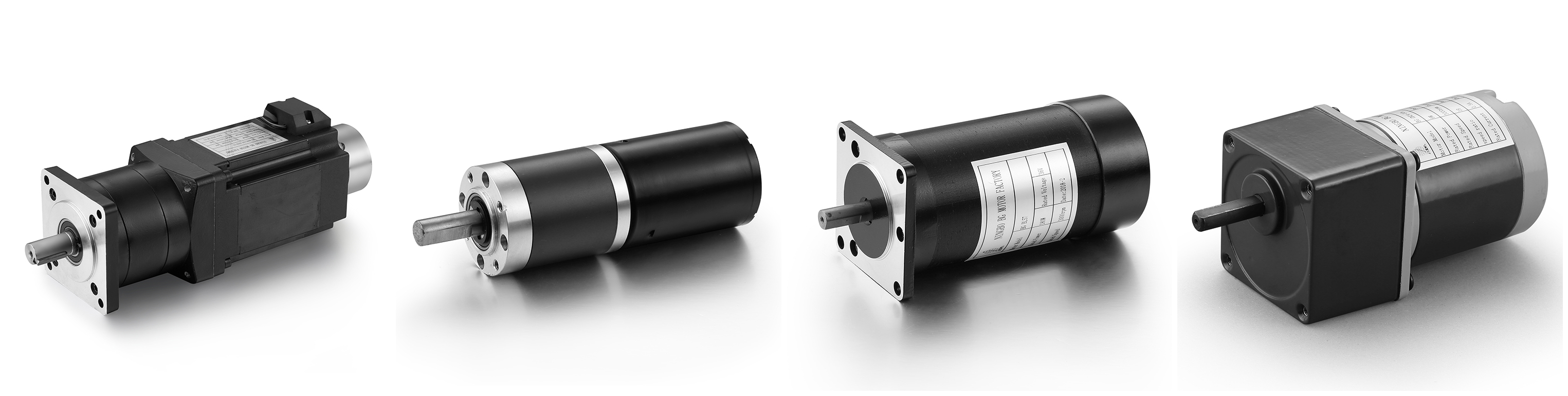

Common motor models are: BG 110BL01, BG62 ZYT01, BG42ZYT01, BG60ZYT12, BG 57BL01, etc.

Motor data:

Power Range: 1W-1000W

voltage Range: DC3V-220V

Rated Speed Range: 1500-6000RPM

Size Range (diameter): 28MM-130MM

Shaft: Based on the drawing you offered, we can process the shaft into corresponding diameter, length and shape.

Mounting hole: We can located the mounting hole with your requirement within reasonable range.

Protection Class: Based on your needs, up to IP65

Install method: Adjust motor into horizontal or vertical arrangement fit for your product.

The parts can be paired with brushless motor: Gear box, brake, and encoder

If you don't know about it, please contact our salesman directly, they will give you professional recommendations and answers based on your products

BACK

BACK

Yesterday, the 138th China Import and Export Fair (Canton Fair) was grandly open…

In the golden autumn of October, the fruits are fragrant. On this beautiful mome…

Dear friends, the 138th Canton Fair will be held in Pazhou, Guangzhou on October…

At BG Motor, we firmly believe that the strength of a team can carry dreams furt…

New Breakthrough at Conifer (Silicon Valley Startup)What’s new?Conifer has devel…

The 2025 World Robot Conference (WRC), held in Beijing, brought together top min…