Precise motion in many mechanical systems depends on effective monitoring and control of motors. The encoder, on the other hand, makes motion control possible by sensing the speed and position of the motor and sending feedback signals to the control components. Motors equipped with encoders are widely used in automatic curtains, conveyor systems, motor assembly equipment and robots. So do you know there are several types of encoders and how to select them?

I. Encoders Can be Classified in the Following Ways.

1. According to the working principle of encoder detection, it can be divided into: magnetic encoder and optical encoder. Magnetic encoders use magnetic field changes to generate and provide the absolute position of the rotor through magnetic induction devices. The optical encoder converts the mechanical geometric displacement or rotation angle of the output shaft into pulse (incremental) or digital (absolute) through photoelectric conversion.

2. According to the Different Ways of Engraving the Code Disc:

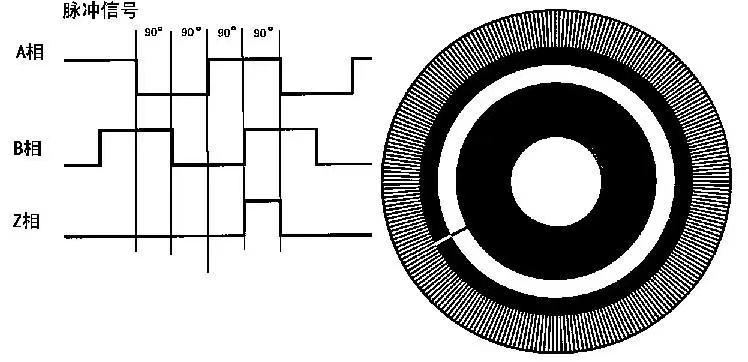

(1) Incremental type: that is, a pulse signal is sent every time the unit angle is rotated (also a sine and cosine signal is sent, and then it is subdivided, and a pulse with a higher frequency is chopped), usually A-phase, B-phase , Z-phase output, A-phase and B-phase are pulse outputs delayed by 1/4 period of each other. The forward and reverse rotation can be distinguished according to the delay relationship, and the frequency can be multiplied by 2 or 4 by taking the rising and falling edges of A-phase and B-phase. ; Phase Z is a single-turn pulse, that is, one pulse is sent out per turn.

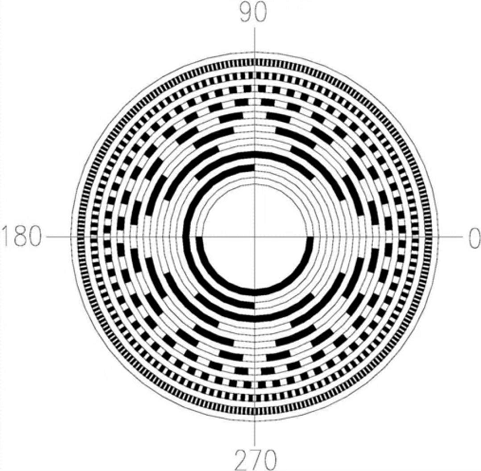

(2) Absolute value type: It corresponds to one circle, and the angle of each reference emits a unique binary value corresponding to the angle. Multiple positions can be recorded and measured through the external circle marking device.

3. According to the output type of the signal, it is divided into: voltage output, open collector output, push-pull complementary output and long-line drive output.

4. Classification in the Form of Encoder Mechanical Installation

(1) Shaft type: Shaft type can be divided into clamping flange type, synchronous flange type and servo installation type.

(2) Bushing type: The bushing type can be divided into semi-empty type, full-empty type and large-diameter type.

II. The Advantages and Disadvantages

Magnetic Encoder:

The magnetic device replaces the traditional code disc, makes up for these defects of the photoelectric encoder, and is more shock-resistant, corrosion-resistant, pollution-resistant, more reliable in performance and simpler in structure.

Optical Encoder:

The photoelectric encoder calculates the accuracy by engraving lines on the code disc, so the higher the precision, the larger the code disc and the larger the encoder volume. Suitable for clean and pollution-free environment; complex structure; large volume.

III. Precautions for Encoder Selection

Three parameters should be noted:

1. Whether the mechanical installation size (including positioning stop, shaft diameter, and installation hole position), cable outlet method, installation space volume, and working environment protection level meet the requirements.

2. Resolution: that is, the number of pulses output per revolution when the encoder is working, whether it meets the design and use accuracy requirements. The number is from 6 to 5400 or higher. The product of the resolution and the frequency multiplier is the number of pulses. The more the number of pulses, the higher the resolution and the higher the accuracy. Generally, most of the encoders have 2500 lines per revolution, 4 times the frequency and output a signal of 10000/revolution.

3. Electrical interface: The common encoder output methods include push-pull output (F-type HTL format), voltage output (E), open collector (C, common C is NPN-type tube output, C2 is PNP-type tube output), long-term driver output. Its output mode should match its control system.

BACK

BACK

Yesterday, the 138th China Import and Export Fair (Canton Fair) was grandly open…

In the golden autumn of October, the fruits are fragrant. On this beautiful mome…

Dear friends, the 138th Canton Fair will be held in Pazhou, Guangzhou on October…

At BG Motor, we firmly believe that the strength of a team can carry dreams furt…

New Breakthrough at Conifer (Silicon Valley Startup)What’s new?Conifer has devel…

The 2025 World Robot Conference (WRC), held in Beijing, brought together top min…