As an important electromechanical energy conversion device in industrial production, the motor has a complex structure, and each component may affect the vibration of the motor. The research on motor vibration involves many aspects, such as electromagnetism, energy conversion, mechanical rotation, etc. During the working process of the motor, the radial vibration of the shaft will inevitably occur. Some vibrations are generated under normal operating conditions. This vibration is allowed for a long time, such as slight vibration of the shaft; but some vibrations are caused by the motor A special signal that appears in a certain faulty operating state, such as excessive radial vibration of the shaft caused by the rotor balance of the motor. The main causes of excessive vibration of the motor shaft are as follows:

01 The rotor of the motor is unbalanced

Rotor unbalance refers to the unbalance that occurs when the rotor mass centerline does not coincide with the rotating shaft rotation centerline. This imbalance will generate a huge dynamic load on the motor rotor and increase the radial vibration of the rotating shaft. According to the mechanism of unbalance, it can be divided into three types: static unbalance, couple unbalance, and dynamic unbalance. Static unbalance means that the rotor mass centerline is away from and parallel to the shaft centerline; The geometric center line intersects with the center of gravity of the rotor; dynamic unbalance refers to an unbalanced state in which the mass center line and the geometric center line are neither parallel nor intersected. The main factors that lead to the imbalance of the rotor quality of the motor are:

(1) Uneven material and inaccurate processing. In the manufacturing process of the motor rotor, due to uneven material or inaccurate processing, the cross section of the rotor is asymmetrical to the center line of rotation, or the residual deformation during the processing and heat treatment of the rotor.

(2) Uneven wear. During the operation of the motor rotor, the uneven wear of the fan blades and the uneven deposition of dirt on the blades cause the center of gravity of the rotor to shift.

(3) Heavy load thermal deformation. Shaft deformation of the motor under heavy load and thermal deformation during operation.

(4) Overhaul damage. When the motor is installed or overhauled, the quality of the rotor is damaged due to technical operations, such as connection errors caused by disassembly or replacement of certain components.

(5) Component aging. As the service time of the motor increases, the aging of the components or the deterioration of the operating environment will cause some parts of the motor to loosen or fall off, resulting in a sudden unbalance of the rotor. Balance, such as motor center hole plugs, moving blades, balance masses and rotor accessories such as pull gold. Among them, the falling off of the moving blade and the pulley is tangentially flying out along the direction of rotor rotation, which is referred to as flying off; the balance mass is loose or falling off due to vibration. According to statistics, about 70% of the sudden unbalance of the rotor is caused by flying off.

02 Bearing misalignment

Bearing misalignment refers to the deviation of the bearing coordinates and installation position, which is often produced by the constraints and restrictions of the processing environment and installation conditions. Due to the structure of the motor, its bearings have different stiffness and damping in the horizontal direction and vertical direction. The misalignment of the bearing will increase the difference in stiffness and damping in these two directions. Even if there is an oil film in the bearing, it cannot make up for it. kind of difference. Even if there is an oil film in the bearing, it cannot make up for this difference. When the degree of misalignment of the rotating shaft is too large, the working condition of the bearing will be deteriorated, additional load will be added on the rotor, the force on the rotor will be uneven, and the rotor may even be unstable or cause friction. Rotor misalignment has a great impact on the motor, and may even cause irreversible damage to the motor.

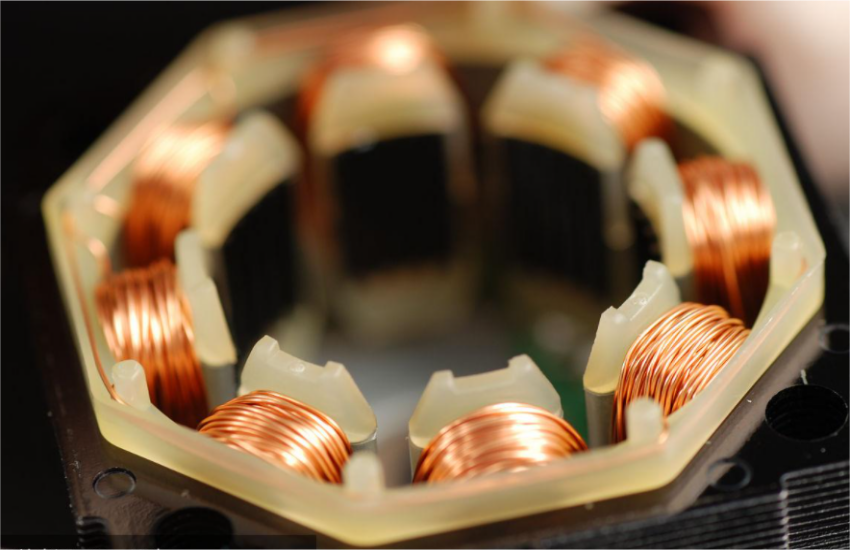

03 Grinding between stator and rotor

During the operation of the motor, due to the unbalanced force on the rotor, the rotation center of the shaft and the geometric center of the rotor do not coincide, which may cause wear or collision between the rotor and the stator. The rubbing between the stator and the rotor is a common fault in the operation of the motor. According to the wear situation, it can be divided into full-circle rubbing and partial rubbing. The full-circle rubbing means that the stator and rotor are always in contact during the rotation of the motor; It means that only part of the rotor is in contact with the stator after one revolution. The rubbing between the stator and the rotor will damage the motor to a certain extent. If it is light, it will increase the vibration of the motor, and if it is serious, it will damage the rotor and stop the motor. There are generally the following reasons for the friction of the stator and rotor:

(1) The machining and manufacturing of the motor rotor is not accurate. As a result, the mass of the rotor is unbalanced or the rotor is bent, resulting in increased vibration of the motor shaft. When the amplitude reaches the value of the dynamic and static gap, it will cause friction between the stator and the rotor.

(2) The rotor is misaligned.

(3) Improper design of the dynamic and static clearance value of the motor. Since the value of the dynamic and static clearance of the motor is generally closely related to the experience of the designer, security inspection and maintenance personnel, if the value is too small, it will cause friction between the stator and the rotor.

BACK

BACK

Yesterday, the 138th China Import and Export Fair (Canton Fair) was grandly open…

In the golden autumn of October, the fruits are fragrant. On this beautiful mome…

Dear friends, the 138th Canton Fair will be held in Pazhou, Guangzhou on October…

At BG Motor, we firmly believe that the strength of a team can carry dreams furt…

New Breakthrough at Conifer (Silicon Valley Startup)What’s new?Conifer has devel…

The 2025 World Robot Conference (WRC), held in Beijing, brought together top min…