Client: Mr.Scott

Country: USA

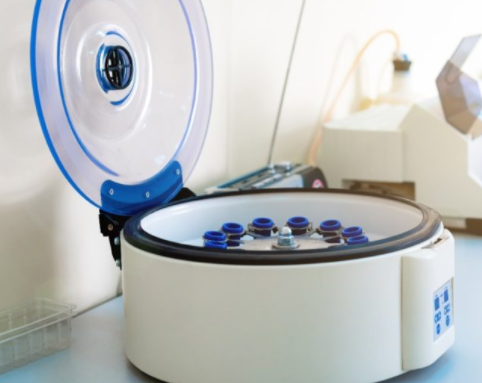

Industry: Centrifugal Machine

The customer is a well-known company in the United States, which has a history of nearly 90 years; They are the world's leading manufacturers of clinical desktop centrifuges. The blood bank centrifuges they produce need to process millions of blood samples every day for patient testing and diagnosis; Because the centrifuge works at a very high frequency every day, the life and noise requirements of the motor will be very high, and it is hoped that the motor can have a long service life;

The required motor data are: rated voltage: 120V AC, rated power: 120W, rated speed: 12000rpm rated torque: 13.5 Oz-in;

Motor Size: Max diameter: 38-50mm , Max Length: 80mm;

Motor life: 10 times a day, 365 days a year, 5-year life, about 13000 hours;

The technical difficulty of this motor is that the service life of the motor, especially at high speed, is a test for every component;

When the temperature of the motor is too high, it must be considered whether demagnetization will occur when the motor runs for a long time;

In the case of high speed, the internal structure of the motor shall be designed to ensure that the motor must have high efficiency;

Size of motor:

According to the customer's requirements, there are clear requirements for the size of the motor; We choose the motor bg5060 of the existing mold to meet the requirements of the customers; Because the motor of bg5060 is an outer rotor brushless motor, the previous structural design was DC, which needs to be converted into AC. we developed a mini control board, especially for customers inside the motor, and the final output of the motor is AC120V voltage; In this way, it can not only meet the size requirements of customers but also meet the voltage requirements;

High speed of motor:

We adopt a 12-pole design structure to ensure the minimum clearance of the motor; The final output rated speed reaches 12000rpm;

Motor power:

In order to ensure that the power of the motor can fully reach the rated 120W, the magnetic raw material of the rotor uses the highest strength neodymium iron boron magnetic raw material, and perfectly matches the number of poles of the motor;

All materials are made of materials with higher insulation grade, so as to ensure good heat dissipation performance and high-temperature resistance at high speed;

BG motor's motor technical solution is very good, which perfectly solves the motor problem for us; Before that, we had been purchasing motors in our own countries, and we were very proud that 100% of them were made in the United States. Since we couldn't find a suitable supplier for this motor, we tried to contact BG motor. We were very satisfied with BG motor's rapid solution and customized motor, and were full of confidence in our long-term cooperation.!

--Mr.Scott (Chief technical engineer)

BACK

BACK

BG Motor insisting on producing the best quality motors for our customers.