Client: Isabelle

Country: United States

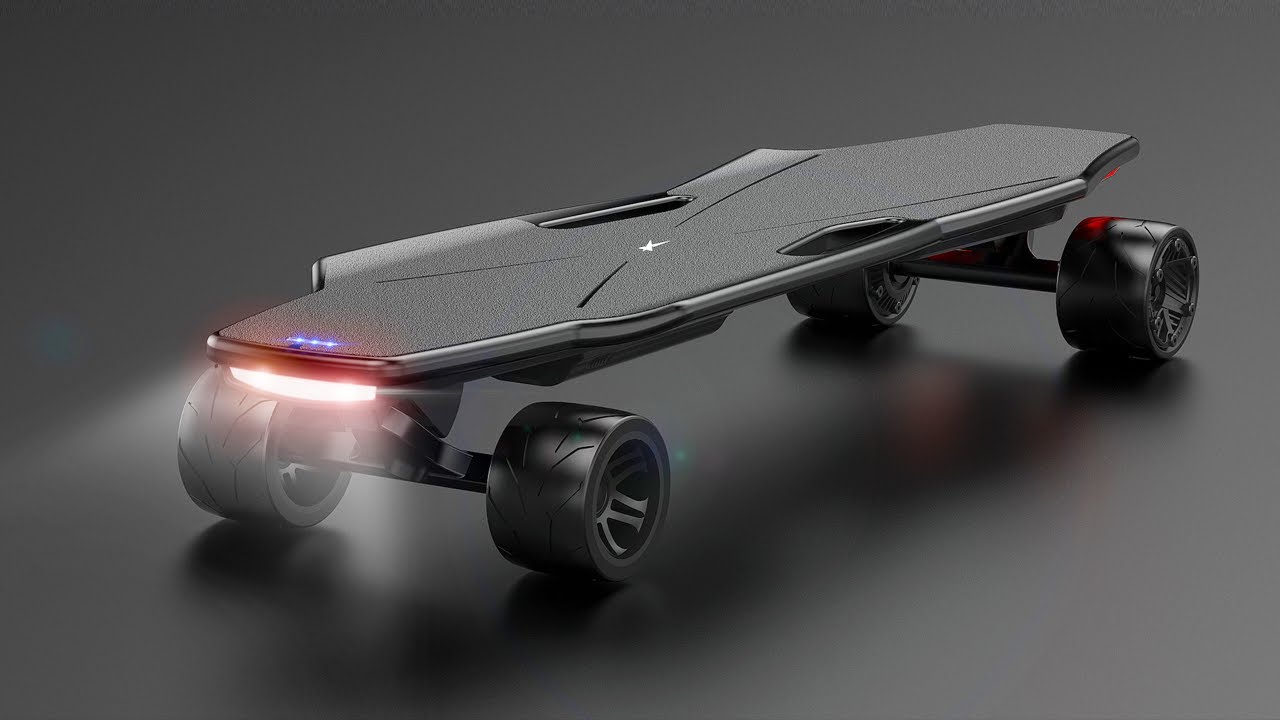

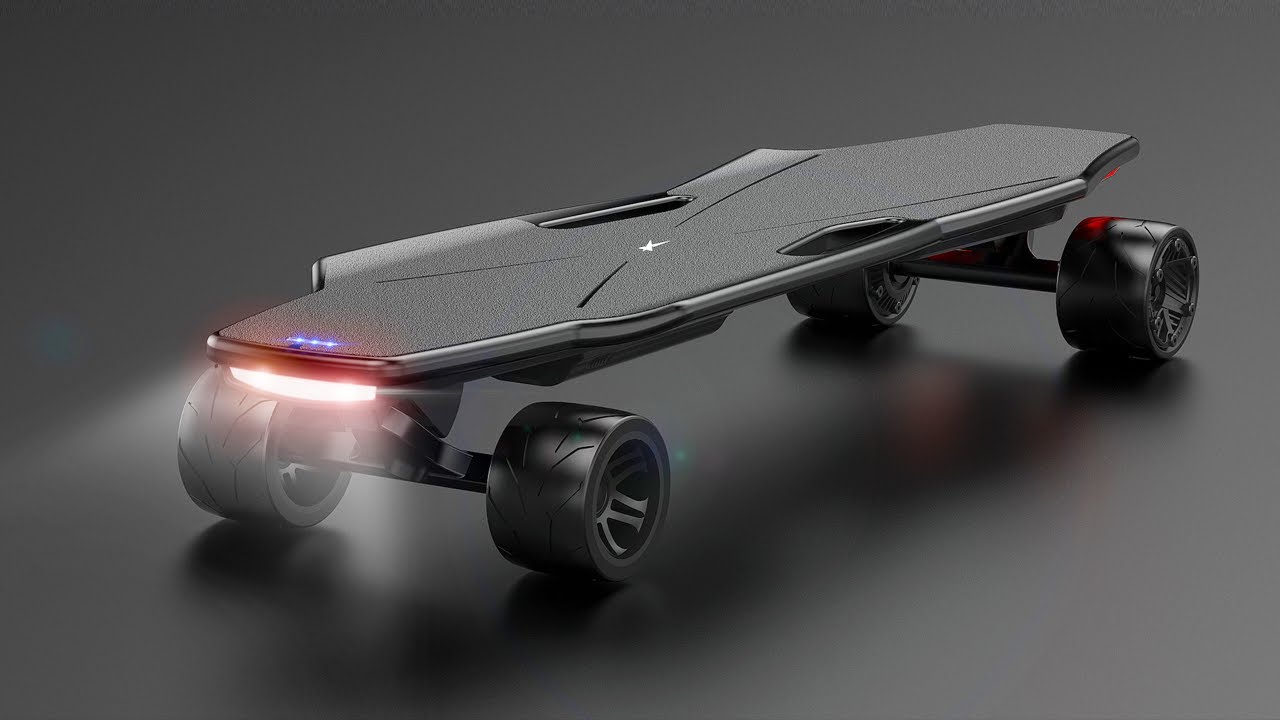

Industry: Electric Skateboard

Cooperation time: 2017

In 2017, customers found us through Google, they are a professional manufacturer of sports skateboard products. Their goal is to make an electric scooter that is easy to operate, has low noise, long motor life, stable operation, and can overcome different terrains. The motor is one of the core components of an electric scooter. Customers want us to work with them to develop motors that meet their needs

Small size: The appearance size of the customer's scooter has been determined, so the motor must meet the size requirements of the customer's product, and the diameter of the motor cannot exceed 50MM;

Low noise: Customers hope that there will be no harsh sound during the operation of the product to ensure that the product will increase the experience of the experiencer during the operation.

Long motor life: The life of the motor product needs to be at least 5000 hours

Low current energy saving: The motor adopts lithium battery. The efficiency of the motor is very important, and the efficiency of the motor must be controlled above 90%.

The motor and drive must be integrated, and the internal space needs to be reduced

The motor can overcome different terrains: the data of the motor must meet the customer's requirements, and the motor must have an IP67 protection level

1. Motor appearance size design: Our engineer team adopts the structure of external rotor brushless motor. When designing the motor, considering high efficiency, the magnetic material is selected from the highest level of NdFeB material; the raw material is selected from the same material as the UAV aircraft; in the design of windings and motor turns, more than 20 designs have been designed through simulation software. This kind of winding mode fully calculates the slot full rate and gap.

2. Noise: The mechanical noise of the motor itself is not high. From the point of view of mechanics and aerodynamics, we have reasonably optimized all the clearances that may generate noise, and the bearings are all imported international bearings.

3. Life: The life of the motor is at least 5000 hours or more

4. Electric bicycles must be able to overcome different terrains: in the case of the same size, the data of BG5060 is higher than that of other motors. Compared with other motors, the data is increased by 48.65%. The product data fully meets the daily use of customers

5. The integrated design of motor and drive saves both space and cost; we solve the drive problem by developing and writing code by ourselves, and control the cost well.

After repeated discussions by our technical team, the motor design and testing were revised, and the "BG5060" motors that met customer needs were all produced within one and a half months.

After 4 repeated sample tests, the product quality fully meets the requirements. Now officially entering the batch!

Very professional, if you have questions and designs in this area, leave it to BG Motor, they will take care of everything for you

BACK

BACK

BG Motor insisting on producing the best quality motors for our customers.