Client: Mr.Clusa

Country: South Korea

Industry:Automatic dryer

Cooperation time: 2012

Due to the rapid development of science and technology, people can use the fully automatic blow dryer after bathing, using high-efficiency and warm air to give customers skin-friendly and sterile physical and mental enjoyment, replacing the worry of using towels, or even avoiding them Damaged skin is damaged again. While relaxing the body and mind, it saves the cost of frequent cleaning of towels, and also contributes to reducing environmental pollution caused by washing and saving precious water resources

Customers find us through Google, they are a professional manufacturer of body dryer products. Their goal is to make a dryer that is small and quiet. At that time, the market was flooded with more expensive body dryer products because customers demanded low noise and small size, and customers valued the motor as one of the core components. Customers want us to work with them to develop a motor that meets their needs.

Small size: The appearance size of the customer's product has been completed, so it is required that our motor can meet the size requirements of the product

Low noise: Since this newly developed body dryer product is for domestic use, the noise during the use of the product needs to be reduced as much as possible and will not affect other indoor personnel

Drying problem: The customer needs to let the product dry most of the human body within the specified time, and the warm air blown out should not make people feel uncomfortable.

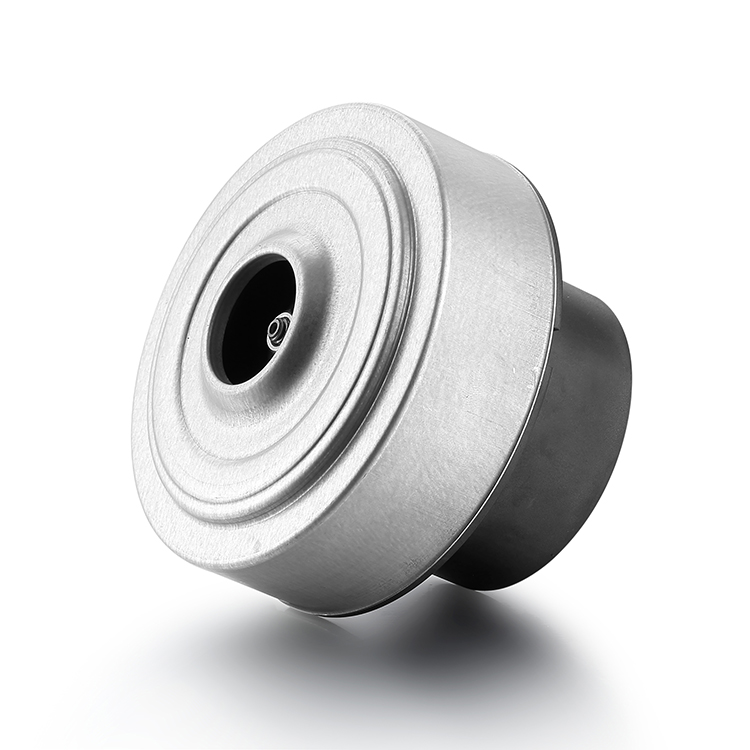

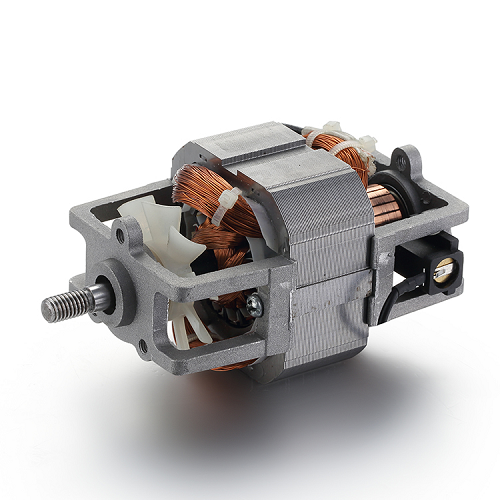

1. Motor appearance size design: Our engineer team adopts the vacuum cleaner motor (BG AC145) structure from BG Motor factory. When designing a (BG AC145- 220V) motor, considering high efficiency, the size of the motor must meet the product requirements; in the design of windings and motor turns, more than 20 winding methods are designed through simulation software, and the slot full rate is fully calculated. and clearance, engineers solve this problem through repeated tests and calculations

2. Noise: The mechanical noise of the motor itself is not high. Because the product needs to be considered from the perspective of indoor use, we have reasonably optimized all the gaps that may generate noise to ensure that the noise of the motor can meet customer requirements during operation

3. Drying problem: According to this problem, engineers use different power vacuum cleaner motors for repeated tests, 500W, 600W, 700W, 800W motors, and let people of different ages feel the wind blowing from the motor, and finally choose A 500W BG AC145- 220V motor.

After repeated discussions by our technical team, the motor design and testing were revised, and the "BG AC145- 220V" motors that meet customer needs have been fully produced within one month.

The customer purchases ten units of the sample after receiving the sample and testing it. The quality fully meets the customer's requirements, and the customer immediately placed a formal order for us.

I've been looking for suppliers in China before, but none of the products they provide meet my requirements, so I didn't have high hopes before working with BG, but now I believe they can provide me with high-quality motors, and I'm very happy work with you.

-Clusa (Chief Engineer)

BACK

BACK

BG Motor insisting on producing the best quality motors for our customers.