Client: Mr. Brule

Country: US

Industry: Milk Shaker

Cooperation time:2021

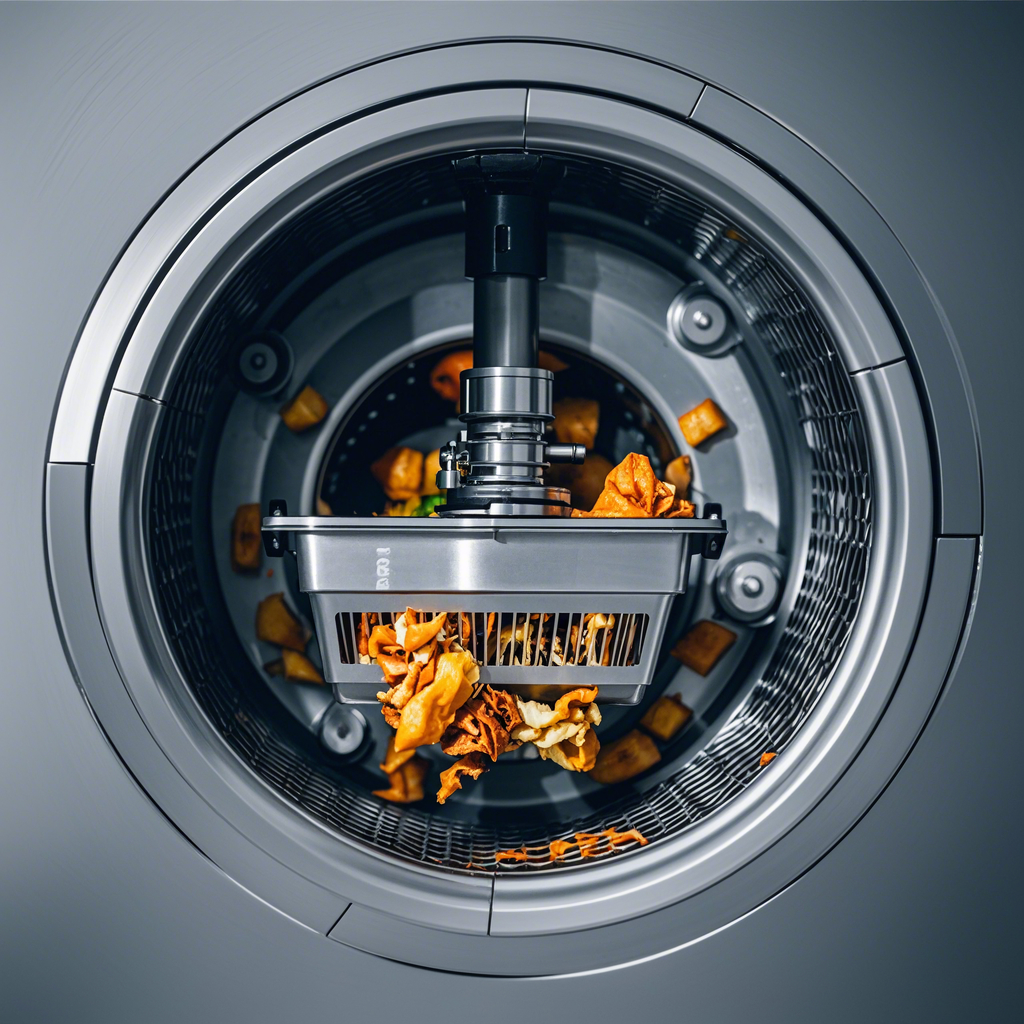

As people pay more and more attention to food safety and hygiene issues, making your own beverages at home has gradually become a trend. Household small juicers, blenders, milkshake machines, etc. are becoming more and more popular in the market.

Mr Brule found us through Alibaba in October 2021. The customer was originally a milk producer. After discovering the market prospect of the milkshake machine, he wanted to develop and manufacture a milkshake mixer by himself, so that the customer could make safe, hygienic and diversified dairy products at home. The motor used by the customer before is a DC brush motor, but the speed is too low and the cost is high, so I want to find a more suitable motor solution.

1. The motor used by the customer before is a DC brush motor, but the cost is high, and the motor speed cannot meet the customer's requirements.

2. For the safety of customers, the motor must be able to automatically stop running when it is overloaded.

3. Low noise: Because the milkshake machine developed by the customer is a household appliance, it is necessary to reduce the noise during the use of the product as much as possible.

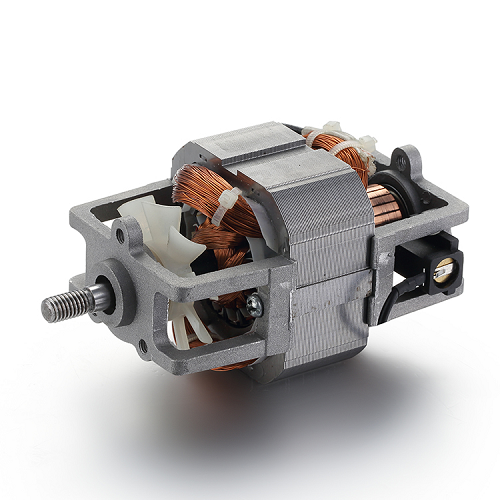

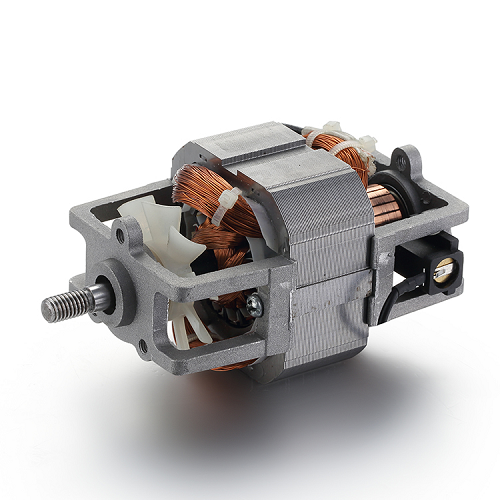

1. Single-phase series motor has the characteristics of low cost and high speed, and is often used in small household appliances, such as mixers, juicers, etc., and single-phase series motor belongs to AC and DC motors, and can also be made into DC motors. .

2. Considering that solid edible raw materials are likely to be used in the milkshake machine process, we appropriately increase the torque of the motor according to our experience in the process of manufacturing the motor. In order to prevent the motor from overloading, the motor is equipped with an overheat protector, and the corresponding protection function is activated when the motor temperature exceeds a certain threshold.

3. The mechanical noise of the motor itself is not high. Since the product needs to be considered from the perspective of indoor use, we have reasonably optimized all the gaps that may generate noise to ensure that the noise when the motor is running meets customer requirements.

One month of motor production, two weeks of customer motor testing, and the customer is very satisfied with the results.

"BG Motor provides a very professional motor solution! Our milkshake machine has now entered the market test and the market feedback is good. It is expected that we will start purchasing larger quantities in the second quarter of next year."

BACK

BACK

BG Motor insisting on producing the best quality motors for our customers.