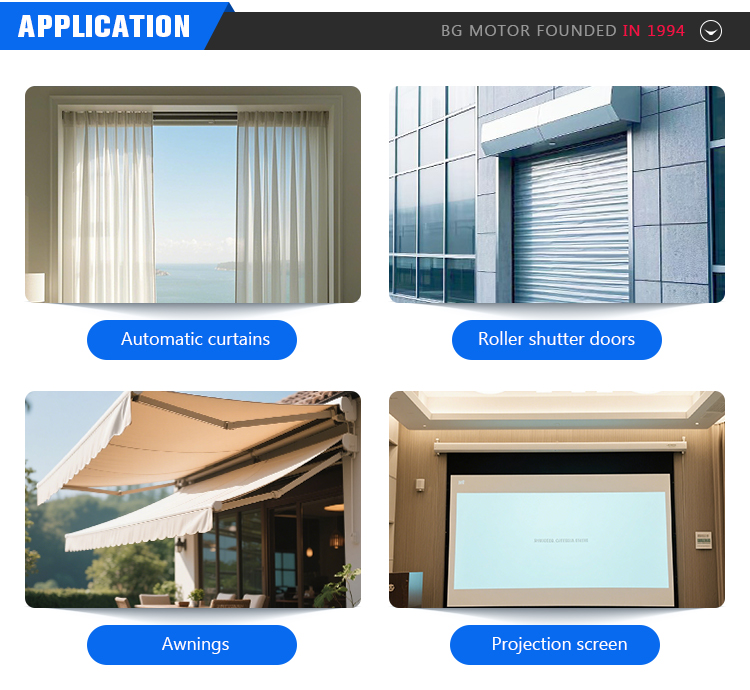

Tubular motors have become the first choice in many industries due to their compact design, smooth operation, small size, high torque, and easy automation. Especially in devices such as motorized roller shutters, motorized curtains, sun visors, etc., tubular motors also play a key role in simplifying control and improving resource utilization as buildings become more intelligent and automated, while increasing the comfort experience.

Tubular motors have become the first choice in many industries due to their compact design, smooth operation, small size, high torque, and easy automation. Especially in devices such as motorized roller shutters, motorized curtains, sun visors, etc., tubular motors also play a key role in simplifying control and improving resource utilization as buildings become more intelligent and automated, while increasing the comfort experience.

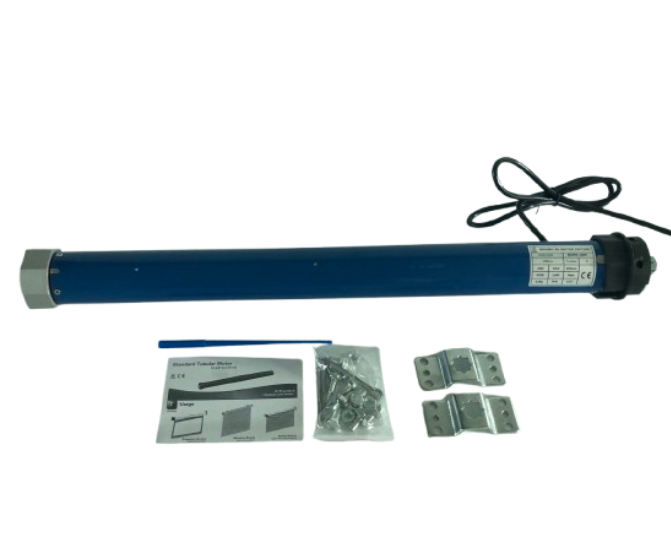

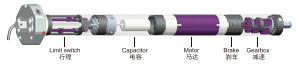

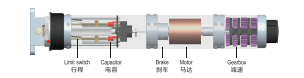

The cylindrical design allows the tubular motor to be hidden inside the tube or roller, saving space and keeping the system clean and streamlined design. Despite its small size, it provides enough torque to lift heavy blinds, doors or curtains. It can be easily integrated with remote controls, smart home systems, or centralized building control systems, and supports smart braking settings with timers, lights, wall switches, and more.

25 series:25mm, 0.7-2N.m, 28rpm, 7.6-25w, continuous working time 5min, 100-240V/50Hz(60Hz)

35 series:35mm, 3-13N.m, 14-33rpm, 98-140w, rated current 0.4-1.6A, continuous working time 4min, divided into 230v/60Hz and 230V/50Hz

45 series:45mm, 10-60N.m, 10-32rpm, 125-235w, 0.5-2.5A, continuous working time 4min, maximum limit 22-45 turns, 220V/50Hz, 120V/60Hz

59 series:59mm, 60-140N.m, 7-15rpm, 340-450w, rated current 1.5-3.7A, continuous working time 4min, 24 turns, 230V/50Hz, 120V/60Hz

92 series:92mm, 230-300N.m, 9-15rpm, 880-1027w, continuous working time 4min, rated current 4.75-8.17A, 22 turns, 230V/50Hz, 120V/60Hz

A variety of electronic built-in acceptance motors are available: electronic stroke limit + built-in wireless receiver + third stroke point + jog dimming function + fixed size roller shutter + single-key reboundable mechanical switch function +···

1. Elegant operation function: The opening and closing curtain has its own light closing and light opening function, and when it runs to the near stroke point, it will decelerate and open more elegantly.

2. Motor memory formation function: with electronic memory stroke, no manual setting is required, and the electronic stroke function can be automatically calibrated

3. Built-in receiving function: with any Felger transmitter, the opening and closing curtain can be controlled individually or group

4. Stop function in case of resistance: the curtain will automatically stop running when it encounters obstacles

5. Light touch start function: hand pull the curtain 20mm to automatically start the motor, no need for manual control

6. Power-off manual function: when the power is off, it is like pulling a curtain by hand

7. Long life and durability: the use of synchronous drive belt, anti-aging and antiseptic, use more than 15,000 times, according to twice a day, can be used for 20 years.

8. External dry contact switch function: through the dry contact, it can be connected to a mechanical switch or a light touch switch

Accessories: tracks, rubber belts, brackets, hanging wheels, transmission box combinations, hooks, finished tracks, etc.

Control system: switches, receivers, transmitters, timers, infrared sensors, etc. BG adopts 433MHS, has strong anti-interference, long transmission distance, high-quality imported chips, stable and reliable product performance and long life

In addition, you can also watch the complete production process of BG Motor through this link.

Ningbo Yinzhou Bogong Motor Factory is located in Ningbo, the capital of the electromechanical industry. As a professional OEM manufacturer specializing in door and window motors and control system solutions, Bogong can customize personalized products according to different customer requirements - from every component to each finished product.

FElERGE tubular motor and remote controller system can be widelyused to Automatic Roller Blinds, Automatic Venetian Blinds, AutomaticRoller Shutter, Automatic Awning, Automatic Roller Door, AutomaticClothes Pole, Automatic Projection Screen . In architectural area it playthe role of natural lighting, heating and cooling, natural ventilationfunction. In same time of convenient operation works as well as savingenergy, In Summer can save around 28% air-condition energy inWinter can save 10 % heating installation energy.

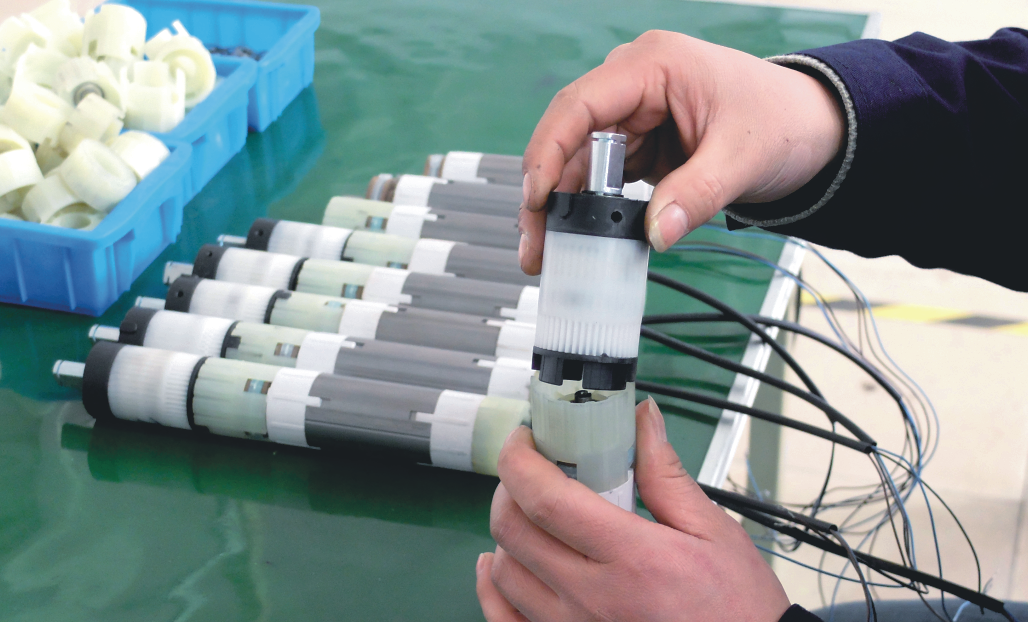

BG roduction lines are designed based on Toyota's U-shaped production line model, with each assembly line meticulously divided into 12 operational steps. While effectively ensuring an 8-hour production capacity of 600PCS, this configuration maximizes operational efficiency. The high degree of flexibility in this setup not only guarantees the adaptability required for OEM production but also effectively meets the diverse needs of various clients.

Every motor from BG undergoes 100% full inspection across 6 processes before shipment, complemented by rigorous sampling inspections from FQC (Final Quality Control) and OQC (Outgoing Quality Control). Additionally, stringent aging tests strictly guarantee both product reliability and traceability.

From the project approval, to research, testingproduction and transportation, there are manyprofessional equipments and technology toensure our product performance and quality canbe controlled in a high level.

BACK

BACK

On April 16, 1963, Martin Luther King Jr. famously wrote in Birmingham Prison th…

The 137th Canton Fair in the spring of 2025 will officially kick off on April 15…

Historical trends in electric vehiclesThe development of electric vehicles (EVs)…

In February 2025, BG Motor ushered in the traditional Lantern Festival celebrati…

The new year has begun, and BG Motor is officially back to work! After a refresh…

Dear Customers, Partners and Employees,On the occasion of the Spring Festival, B…