Founded in 1994, BG Motor has more than 30 years of experience in motor production, and has always focused on the R&D and manufacturing of high-quality motors. We not only have strong technical strength, but also equipped with advanced automated production lines, including DC brush motors, DC brushless motors, AC motors, worm gear motors and planetary geared motors, to ensure the efficient and stable output of products.

Customized service is our core strength. We provide free customized solutions with a deep understanding of the specific needs of our customers, and design and manufacture the most suitable motor for each customer from the application scenario to optimize performance, improve efficiency and reduce energy consumption. Whether it is in the fields of smart home, medical equipment, industrial automation, auto parts, intelligent robots, etc., we can provide precisely matched drive solutions to help customers solve technical problems in practical applications and enhance product competitiveness.

High efficiency and energy saving, no carbon brush design, longer life

Low noise, low interference, suitable for high-end precision equipment

The speed control is accurate, and it can be intelligently adjusted with the driver

Suitable for high-end applications such as power tools, smart homes, robots, medical devices, etc

Simple structure, low cost and high cost performance

Large starting torque, suitable for short-term and high-load scenarios

Easy to maintain, suitable for small and medium-sized equipment

Mainly used in household appliances, small power tools, auto parts, etc

High torque, high precision, low noise

Small size and compact structure, suitable for space-constrained equipment

Can be matched with brushless/brushed motors to meet different needs

Used in automation equipment, smart door locks, medical equipment, etc

Strong self-locking function, suitable for preventing equipment from rotating

High reduction ratio, high output torque

Suitable for applications that require high torque output at low speeds

Commonly used in electric sofas, electric beds, industrial control equipment, etc

High speed, high torque

Compact and miniaturized design, high IP rating such as waterproof and dustproof protection type

It can be used in a variety of household appliances such as coffee machines, grinders, juicers, meat grinders, bathroom fans, etc

BG Motor has five automated production lines to ensure high efficiency and consistency in mass production of products

Precision machining equipment is used to ensure the stability and reliability of the motor

CE, CCC, FCC, ISO9001 certifications ensure compliance with international quality standards

Adopt strict quality inspection process, including noise test, load test, life test, etc

It holds a number of practical patents and has significant technical advantages

The energy efficiency level of the motor meets the high efficiency standard, helping customers reduce energy consumption

The use of environmentally friendly materials, in line with international environmental protection requirements, can be successfully exported to Europe and the United States

Customized support for non-standard motors

In many applications, standard motors do not fully meet the specific needs of the customer. With more than 30 years of experience in the industry, BG Motor not only provides standardized motor products, but also provides users with precise customized support to obtain unusual data, dimensions and models to ensure that the motor is perfectly matched to their application.

✅ Full technical parameters

Provide detailed specifications of torque, speed, current, voltage, noise level, life test data and other specifications of all motors

Detailed performance curves can be provided according to different load conditions

✅ Engineering simulation data

Provide performance simulation data of the motor under different temperatures, humidity, loads and other working conditions

Finite Element Analysis (FEA) to predict the heat distribution of the motor, electromagnetic field strength and other data

✅ Lifetime and reliability data

Provide test data of the motor under different working environments (high temperature, low temperature, high humidity).

Fatigue test, impact test, life curve analysis can be provided according to customer needs

✅ Special environmental adaptability data

Provide IP level test data for waterproof, dustproof, shockproof and other requirements

Suitable for medical, power tools, outdoor equipment and other fields

✅ Custom-sized motors

Provide non-standard size design, which can adjust the diameter, length, shaft diameter and installation method of the motor

Suitable for applications with limited space and special installation methods

✅ 3D/2D design models

Complete 3D (STEP, IGES) and 2D (DXF, DWG) models are available for direct integration into the product design

Support engineers to simulate in CAD, SolidWorks, Creo, AutoCAD, etc

✅ Rapid sample customization

With rapid proofing ability, samples can be provided in a short time for adaptation testing

Suitable for prototype development, special experimental projects, small batch testing

Fast response and efficient service

Our team consists of experienced engineers, business staff and technical support experts to ensure that customers’ needs are quickly and accurately understood.

Provide multilingual support (English, German, Spanish, etc.) to ensure that communication between customers around the world is accessible.

✅ Response mechanism within 24 hours

Customer's technical consultation, quotation requirements, project feedback, BG Motor guarantees to give a preliminary reply within 24 hours.

Complex technical problems, promise to give detailed solutions or optimization suggestions within 48 hours.

✅ Regular project follow-up

BG Motor will arrange regular return visits to customers to ensure that the project progress is transparent and customer needs are implemented.

Each order is followed up by a dedicated person to avoid missing information and delays.

✅ Clarify the delivery cycle and strictly implement it

When confirming the order, we will confirm the detailed production plan and delivery cycle with the customer, and strictly follow the schedule.

Equipped with 5 automated production lines, greatly improving delivery efficiency and avoiding delays.

✅ One-stop solution to reduce the burden on customers

BG Motor provides one-stop motor solutions from R&D, design, production to after-sales, so that customers do not need to coordinate with multiple suppliers and avoid delays caused by communication problems.

We can provide personalized customized services and quickly respond to changes in customer needs.

✅ Strict quality control to avoid repeated rework

All motors are strictly tested (torque test, life test, temperature rise test, etc.) before leaving the factory to ensure that the quality is qualified.

Reduce the risk of secondary communication and rework due to quality issues, and improve the overall efficiency of the project.

✅ Transparent service with full traceability

BG Motor will have a clear responsible person for each project, and all progress, problems, and delivery can be tracked at any time.

The customer can contact the person in charge at any time through email, video conference, and instant messaging tools (such as WeChat, WhatsApp) to obtain the progress of the project.

✅ Solve the problem as soon as possible

If any technical or production issues arise during the project, our team will provide immediate feedback and propose solutions instead of passing the buck.

Provide fast repair, replacement and upgrade services to ensure that the customer's production will not be affected.

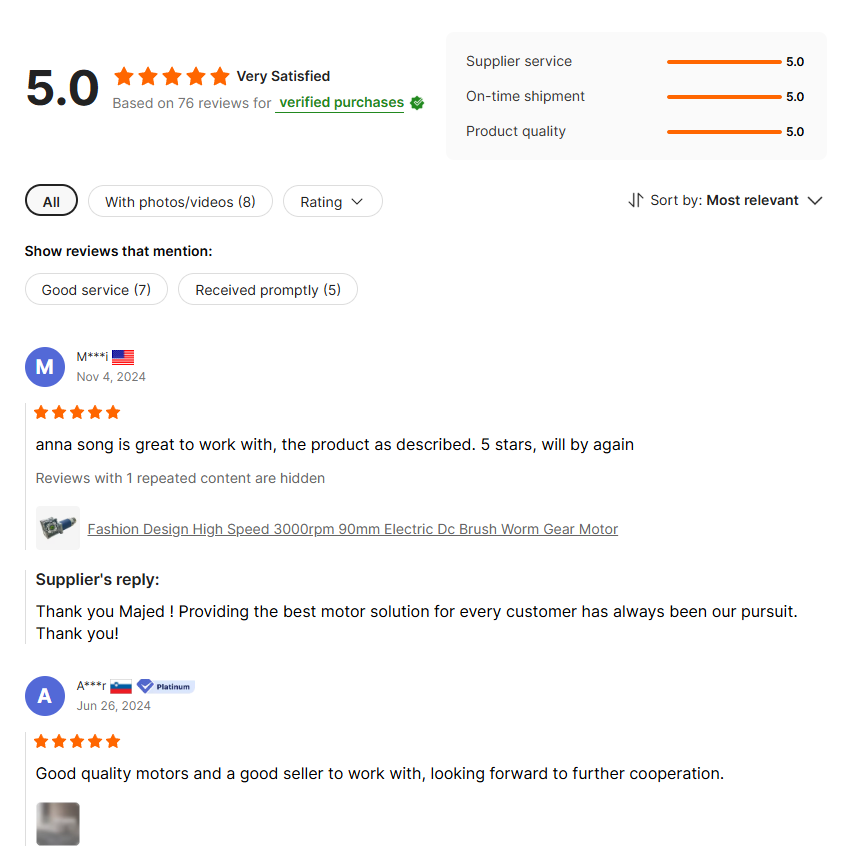

✅ Long-term cooperation, word-of-mouth witness

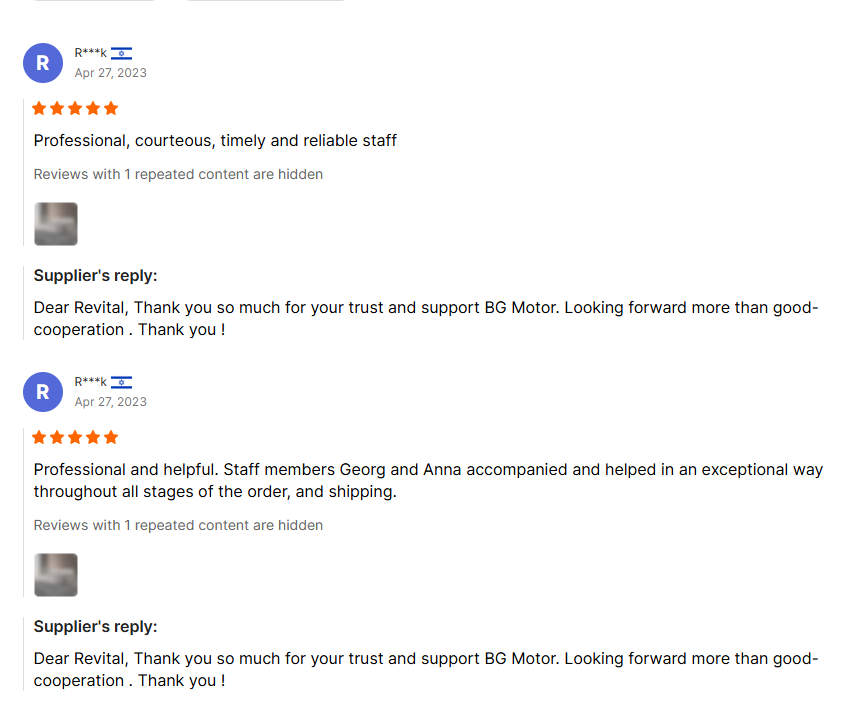

BG Motor has established long-term cooperative relationships with many well-known brands around the world, and our customers highly recognize our reliability and sense of responsibility.

Customer testimonial: BG Motor never shies away from problems, but comes up with solutions as quickly as possible, which is exactly why we chose them!

BACK

BACK

Focusing on the industrial trend of the 2025 Canton Fair, BG Motor continues to …

On April 16, 1963, Martin Luther King Jr. famously wrote in Birmingham Prison th…

The 137th Canton Fair in the spring of 2025 will officially kick off on April 15…

Historical trends in electric vehiclesThe development of electric vehicles (EVs)…

In February 2025, BG Motor ushered in the traditional Lantern Festival celebrati…

The new year has begun, and BG Motor is officially back to work! After a refresh…