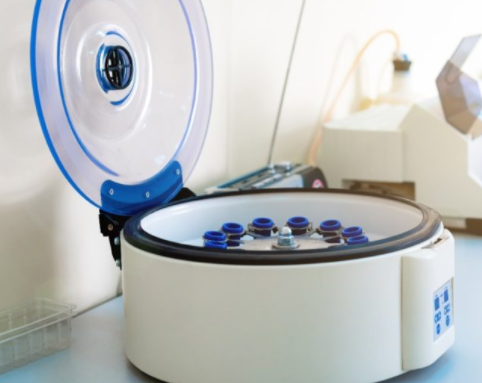

Medical equipment-Medical equipment

Client: Andrew Oyama

Country: UK

Industry: Medical Equipment

Cooperation time: 2016

With people around the world becoming more and more health conscious and having regular medical check-ups every year.As our company's vision is to drive the life better, we are keen to move into the medical equipment industry. In 2016, through the introduction of other British customers, we met with a 50-year-old medical device manufacturing company in the UK.After our in-depth conversation with them, they have a new project, and hope we can participate in their product design, as well as using the most advanced technology in the motor industry, and develop a long-life medical device with them. After about 6 video conferences, we clarified the whole idea of the customer and the motor product they want to make.

What they need:24v low noise ,high torque(25N.m) DC Planetary motor.

The motor was requested to continuously work for 24 hours

Low noise,≤60dB

Lifespan,required to be over 20000 hours

Small size,need to reach 20N.m within the diameter below 58mm

Based on the requirement,what they need is a DC motor inline with gear box, after our careful consideration and research, DC planetary gear motor can make that, relatively easy to install, and the efficiency of the motor can reach more than 85%. We use the best ball bearings, all the raw materials inside the motor with the highest H-class insulation level, to ensure that the service life of the motor will reach more than 20,000 hours.The motor is a physical performance The noise of the motor can be controlled at 50dB, the main source of noise is the planetary gearbox, our engineers calculate through the principles of mechanics and structure, using the theory of the principle of the bevel to change the material and direction of the gear to ensure the lowest noise of the motor.

After receiving our motor products, the customer passed 3 different performance and lifespan tests, all of which were completed to meet their standards.

When we started this project.To be honest,we don’t trust BG Motor to meet our quality requirements, we usually look for Japanese suppliers to work with. After communicated with them,the whole team of BG Motor was very enthusiastic and professional, we exchanged hundreds of emails.

They impressed me,very smart,and also giving their opinions and ideas which solved us a lot of trouble and save time on the motor.

-Andrew Oyama

BACK

BACK