A brushless DC motor is a type of DC motor that does not use brushes and commutators. Because of its high efficiency, controllability, low noise, long life and other advantages, it is widely used in various precision instruments and equipment, such as industrial automation, medical centrifuges, smart home equipment and so on.

You might say: everything is so wonderful, what makes them start turning?

So with your original curiosity, let's explore the mystery of operation together.

Motors play a vital role in the operation of various equipment. As the core component that provides power, the motor directly affects the performance, efficiency, reliability and service life of the equipment. The following are the importance of the motor for the operation of the equipment:

Motors are the main power source for many devices such as robots, automated production lines, home appliances, medical equipment, etc. It drives the operation of various parts of the equipment by converting electrical energy into mechanical energy. For example, in a robot, a motor drives the robot's joints and moving parts; In industrial equipment, electric motors provide the necessary torque and speed to ensure that the equipment operates efficiently and according to its intended function.

The performance of the motor directly affects the operating efficiency of the equipment. High-efficiency motors minimize energy loss and improve the overall efficiency of the equipment. For example, brushless DC motors (BLDCs) provide higher conversion efficiency by reducing brush friction and electrical losses, helping devices to complete their tasks with lower energy consumption. This is particularly important for energy saving, emission reduction, and reduced operating costs.

The stability of the motor determines the reliability of the equipment. In many industrial and production equipment, motors must be able to withstand long periods of high-load operation to ensure trouble-free, continuous and stable operation. High-quality motors have a longer service life and fewer failure rates, which is essential to ensure the long-term stability of the equipment.

Precise control of the motor is essential for some high-precision applications. For example, in an automated production line, the precise control of the motor directly affects the precision of the machining and assembly process, which in turn determines the quality of the product. In the field of robotics, motors are able to control the robot's motion flexibility and response speed, allowing it to perform complex tasks and operations.

Many motors (especially inverter motors, servo motors, etc.) are able to adjust the speed and torque according to demand, providing greater flexibility and adaptability to the equipment. By adjusting the speed and load capacity of the motor, the equipment can be adjusted accordingly according to the different requirements of the working environment and tasks. For example, in a conveyor belt system, the speed of the motor can be adjusted according to the needs of material conveyance, thus improving the efficiency and accuracy of the production line.

The motor has a great impact on the noise and vibration of the equipment. Due to its brushless design, the brushless DC motor (BLDC) can significantly reduce noise and vibration, providing a smoother and quieter operating environment. Low-noise motors are especially important in equipment that requires quiet operation, such as medical equipment, home appliances, etc.

The performance of the motor also affects the safety of the equipment. Poor-quality, poorly designed, or overloaded motors can cause overheating, short circuits, or failures, which in turn can compromise the safety of your equipment. High-quality motor design and precise temperature control system can effectively avoid these problems and ensure the safety of the equipment in long-term use.

With the continuous development of intelligent manufacturing and automation, the role of motors in automation equipment is becoming more and more important. The high-performance motors are capable of supporting complex motion control, automatic adjustment and intelligent operation. For example, in automated robots and AGVs (automated guided vehicles), motors work closely with the control system for precise path planning and task execution.

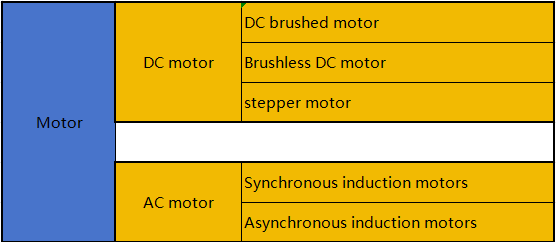

Motors are mainly divided into two types, DC motors and AC motors.

DC motors are further divided into: DC brushed motors, DC brushless motors and Stepper motors

AC motors: Synchronous motors and Asynchronous motors.

Among them, DC motors use DC current drive and are mainly used in power tools, electric vehicles, fans, robots and other applications

AC motors use AC power and are mainly used in industrial production, home appliances, pumps and other equipment.

In this article, we will focus on the technical description of brushless motors.

Brushless DC Motor (BLDC) is an electric motor that uses an electronic controller to replace the mechanical commutator in the traditional brushed motor to control the rotation of the motor rotor.

The structure of the brushless DC motor mainly consists of the following core parts:

(Power-on mode, power-up phase,synthesized magnetic flux )

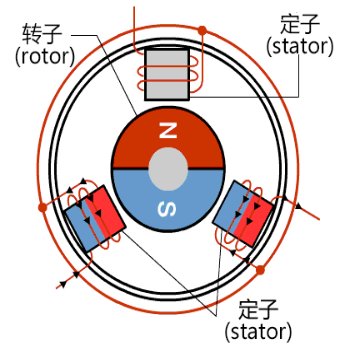

Stator:

The stator is the stationary part of the motor, usually composed of multiple electromagnetic coils. It is the main source of magnetic field of the BLDC motor. By energizing the stator coil, an alternating magnetic field is generated to drive the rotor to rotate.

The stator is usually made of laminated silicon steel sheets to enhance the concentration of the magnetic field and reduce energy loss.

Rotor:

The rotor is the rotating part of the motor, usually made of permanent magnetic material (such as neodymium iron boron magnets). The rotor and stator interact through the magnetic field to achieve rotation.

The rotor of the brushless motor has no brushes, which reduces wear and heat generation, thereby greatly extending the service life of the motor.

Electronic Commutator:

The commutation of the brushless DC motor is completed by an external electronic controller. The actual position of the rotor is determined by a sensor that detects the rotor position (such as a Hall sensor), and then the electronic switch is controlled based on the position and speed information to ensure the correct switching of the current in the stator coil, thereby controlling the direction and speed of rotation of the rotor.

This electronic control method avoids physical contact between the brush and the commutator, thereby reducing friction loss and noise.

Controller:

The brushless motor needs to be matched with a controller to achieve precise control and commutation. The controller controls the speed, torque and position of the motor by supplying current to the stator winding and adjusting the magnitude and direction of the current.

The main task of the controller is to adjust the operating state of the motor according to the sensor feedback to ensure that the motor runs smoothly and efficiently.

Hall Sensor:

The Hall sensor is used to detect the angle and position of the rotor and provide feedback signals to the controller. Through the Hall sensor, the controller can accurately control the timing of current switching, thereby ensuring precise control of the motor at various positions.

Bearing:

The bearing is used to support the rotor and allow it to rotate smoothly. Brushless DC motors usually use high-precision bearings to ensure that the motor can maintain low friction and stable operation when running at high speeds.

The working principle of brushless DC motor is based on the law of electromagnetic induction. The current on the stator generates an alternating magnetic field, and the permanent magnet on the rotor interacts with the magnetic field of the stator to generate torque. When the direction and magnitude of the current in the stator coil changes, the direction and magnitude of the magnetic field also change, driving the rotor to rotate continuously.

In a brushed motor, the commutator contacts the rotor through the brushes to control the switching of the current; in a brushless motor, the electronic controller and Hall sensor replace this physical structure, achieving a more efficient and frictionless commutation process.

· Long life: Since there is no wear of brushes, the service life of brushless motors is much longer than that of brushed motors.

· Low noise and low vibration: Brushless motors have no friction between brushes and commutators, so they are quieter and vibrate less during operation.

· High efficiency: There is no brush friction loss, and the rotor is made of permanent magnet material, which has high energy efficiency.

· Low maintenance requirements: Since there are no brushes, the complexity and frequency of motor maintenance are reduced.

· Higher power density: Brushless motors can usually provide more power in a smaller volume, which is suitable for applications with compact space requirements.

·Household appliances: such as vacuum cleaners, air conditioners, electric fans, etc.

· Power tools: such as electric drills, electric screwdrivers, etc.

· Robots: used to drive robot joints, electric wheels, etc.

· Electric vehicles: motors used to drive electric vehicles.

· Drones: as drive motors for flight power systems.

· Brushless motor fan: silent, energy-saving and environmentally friendly, more suitable for home and office use

· Large equipment: Brushless motors are the first choice for the production and manufacturing of various large equipment because of their precision performance and high efficiency.

Brushless DC motors have gradually become the preferred motor type for many industries and applications due to their high efficiency, low noise, long life and good speed regulation characteristics.

Founded in 1994, BG motor is a motor manufacturer and supplier integrating R&D, production and sales.

BG Motor is supported by quality and driven by technology. Strict quality control and customized solutions have won us a lot of praise from customers. In the future, we will continue to be committed to becoming the most trusted motor manufacturer in the world.

Over the past few decades, the company has been constantly exploring and researching. Up to now, BG Motor has developed into a manufacturer with 12,000 square meters of plant and fully automatic production lines, making the cost of products more advantageous. The main products are DC brushless motors, DC brush motors, AC motors, worm gear motors, vacuum cleaner motors, robot motors and motor accessories.

In the field of brushless motors, we have multiple patents and a professional R&D team, providing customized services, striving to provide customers with the most satisfactory motor solutions, and becoming the world's most trusted motor manufacturer.

BG motor has always been committed to its core values of doing things with heart, striving for excellence, taking responsibility, and being honest. It is our mission to turn a better life around and continue to provide customers with the best motor solutions and services. In the future, we will continue to forge ahead, just as the founder originally wished, and insist on providing customers with the highest quality motors.

BACK

BACK

Electric Motors: The Backbone of Modern Machinery Electric motors power our wor…

Since its establishment in 1994, Bogong has been deeply involved in the …

Precision and power are essential in modern machinery. High torque motors fulfil…

Torque in a motor refers to the rotational force generated to perform work. It’s…

Thanksgiving in the United States is a major holiday, celebrated on the fourth T…

Alternating current (AC) powers nearly every modern device. However, many people…